Mastering Design Instrumentation Training with Smart Plant Instrumentation

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Instrumentation is one of the vital factors in the design and implementation of control systems, covering complex automation processes, safety, and efficiency in today's fast-moving industrial scenes. This type of skill has never been in greater demand than it is in current times. Some of the skills these designers must be trained in include but not be limited to Design Instrumentation Training and Smart Plant Instrumentation Training. Knowledgeable effective designers will be familiar with both practices so as to thrive effectively in the modern industrial environment.

Understanding Design Instrumentation Training

Design instrumentation training is a direct medium through which professionals can understand technical instrumentation design and implementation. What essentially constitutes an instrumentation system comprises sensors, transmitters, controllers, and so on, considering regard to monitoring as well as controlling an industrial process. Proper training aids engineers with knowing how to select the right instruments to integrate into a system, while further ensuring they function well.

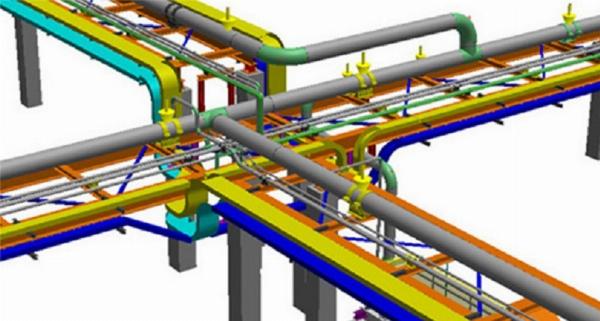

Design instrumentation is essentially the design of a system architecture with optimal balance between accuracy, reliability, and cost efficiency. The instrumentation training usually incorporates aspects such as instrument selection, signal conditioning, control loop design, and systems integration for engineers. They will learn to design instrumentation systems that are not only technically adequate but also scale with industrial demands.

Instrumentation Training: A Hands-on Experience Design Engineers experience real-life case studies with hands-on approach. They understand the applied challenges they are likely to encounter onsite. Instrumentation training also equips engineers with the ability to troubleshoot such prevalent problems as interference of signals or malfunctioning of sensors, allowing the system to work throughout highly demanding environments.

Instrumentation Training for a Smart Plant

Smart Plant Instrumentation Training offers this niche software designed to streamline instrumentation systems design. Hexagon's Smart Plant Instrumentation tool is a full-fledged software solution that automates many tasks involved in the management of instrumentation data throughout a project's lifecycle. One central place where instrumentation work complexities are taken care of Design and its upkeep. Complete operations can now manage instrumentation work complexities.

Training in Smart Plant Instrumentation enables the engineers to perform a data organization even across many systems and project stages in an efficient manner. It simplifies making reports, creating loop diagrams, and so on, thereby managing wiring details. The exposure of Smart Plant Instrumentation among the engineers enhances their ability and minimizes errors in the routine works as well as saves time doing so accurately.

Smart Plant Instrumentation Training makes the engineers conversant with advanced features such as data validation and version control. All these play a very essential role in the management of large-scale projects. The software interfaces perfectly with other design tools, thereby facilitating efficient coordination among different teams and systems. In modern projects, precision and efficiency are high on the order of precedence.

Working of Design Instrumentation in Conjunction with Smart Plant Instrumentation

Whereas Design Instrumentation Training helps build in-depth foundational knowledge on robust instrumentation systems, Smart Plant Instrumentation Training goes a step further into the automation of such systems and optimizing them for the best results possible. Together, they provide an all-rounded package whereby these engineers can cope with the stringent demands placed upon them in the modern industrial world.

For example, engineers may be required to design an instrumentation system that would measure temperature, pressure, and flow within a chemical process in a big industrial plant. They would go through Design Instrumentation Training wherein they will learn about how sensors have to be selected and about the planning and design of control loops to ensure that it is safe and efficient. After the design phase, there follows training on Smart Plant Instrumentation Training to make it possible for them to handle data from the system with little or no problem, generate documentation after some time, and perform maintenance of the system.

The integration of Design Instrumentation Training into Smart Plant Instrumentation Training is what helps engineers bridge the gap created during the design of the system and information management. This combination ensures that instrumentation systems created are well-designed and hence easy to maintain and update throughout the project lifecycle.

Benefits of Mastering Both Design Instrumentation and Smart Plant Instrumentation

There are plenty of rewards to learning Design Instrumentation Training and Smart Plant Instrumentation Training. In addition to teaching the engineer, it brings added value by making the level of engineering skill higher, hence boosting the price of an engineer in the marketplace. Some of these benefits include the following:

Increased Efficiency: With much of the labor-intensive work in instrumentation systems automated by Smart Plant Instrumentation, the engineers have leeway in focusing on design and problem-solving.

Better Accuracy: Use of Smart Plant Instrumentation would help engineers avoid errors, ensuring instrumentation data in the entire project lifecycle is accurate and updated.

Streamlined Workflow: Smart Plant Instrumentation enables designing other processes on a traditional design workflow in such a way that it integrates with other workflows. All teams that are involved in the projects would be able to work seamlessly and communicate with each other efficiently, eliminating all forms of bottlenecks.

Scalability: As projects grow into complexity, the requirement to process instrumentation data efficiently increases. Smart Plant Instrumentation has everything needed to scale up without compromise on control and accuracy.

Compliance and Documentation: Both Design Instrumentation Training and Smart Plant Instrumentation Training allow engineers to easily generate all relevant reports and documentation required by regulatory compliance in industries such as oil and gas, pharmaceuticals, and manufacturing.

Career Opportunities and Industry Demand

Going forward, the induction of industries into automation is not going to stop; simultaneously, the demand for professionals having skills in Design Instrumentation Training and Smart Plant Instrumentation Training will be increasing, and companies will also require engineers who can design robust, scalable systems while also managing data properly by using advanced software tools.

Training in all these competencies can lead one into various positions within the oil and gas, energy, manufacturing, and chemical processing industries. There are many career paths open for instrumentation engineer, automation engineer, and control systems engineer, among others. The training in this book, which covers both design and smart plant instrumentation, will help readers position themselves to address these careers well.

Call to Action

Whether you want to progress your career through advanced instrumentation skills, we can assist with both Design Instrumentation Training and SmartPlant Instrumentation Training in mastering the tools and techniques for more complex industrial projects. Get in touch with us today on how we can help enhance your expertise in this fast-changing industry!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.