Metal Injection Molding India for Precision Parts

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

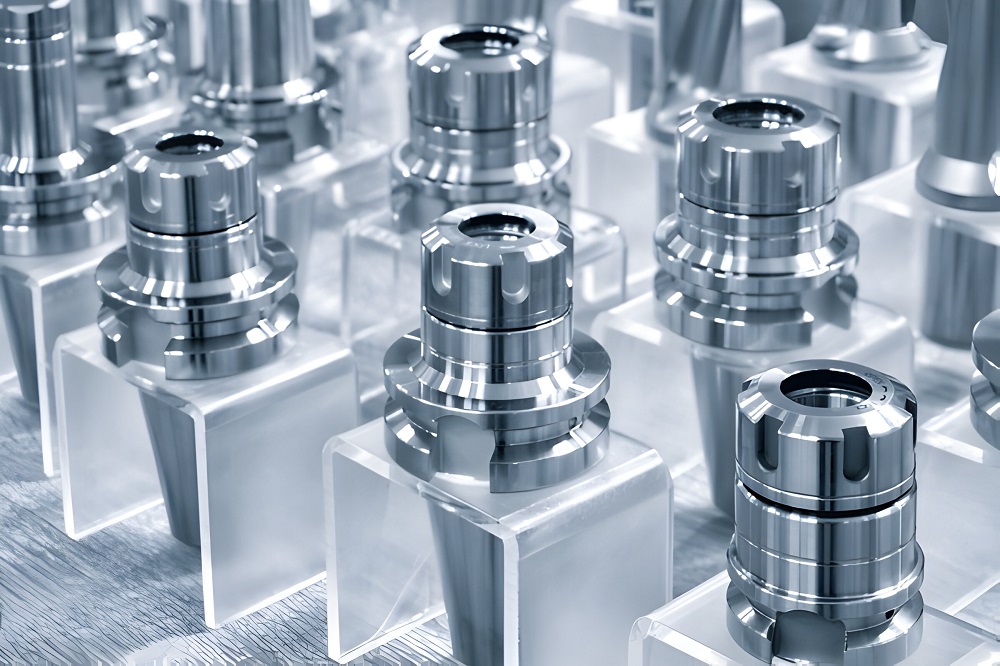

Modern industries need small, strong, and accurate metal parts. These parts must meet tight tolerances and complex shapes. Traditional methods like casting or machining often fall short. That’s where Metal Injection Molding (MIM) comes in.

India is now a leading provider of this technology. Many global companies trust Metal Injection Molding India for making precision parts. In this article, we will explore what MIM is, how it works, and why India is a top choice for precision metal parts.

1. What Is Metal Injection Molding (MIM)?

Metal Injection Molding is a process that combines metal powders and plastic binders. This mix is molded into shape and then heated to remove the binder. Finally, the part is sintered to form solid metal.

Steps in the MIM process:

Feedstock preparation – Metal powder is mixed with a binder.

Injection molding – The mix is injected into a mold to create the part shape.

Debinding – The binder is removed from the molded part.

Sintering – The part is heated at high temperature to form dense metal.

This method is ideal for making small and complex metal parts with high precision.

2. Why Precision Matters in Industries

Precision parts are used in many industries. These parts must fit perfectly, work smoothly, and last long.

Industries that need precision parts:

Automotive – Fuel systems, gears, sensors

Medical – Surgical tools, implants

Aerospace – Miniature brackets, locks

Consumer electronics – Connectors, mobile parts

Defense – Triggers, safety parts

Even a small error in part size can cause failure. That’s why precision is critical.

3. Advantages of MIM for Precision Parts

MIM offers several benefits over traditional manufacturing methods.

Key Benefits:

High accuracy – Tight tolerances with minimal machining

Complex shapes – Design freedom for intricate parts

Smooth surface finish – Reduces need for polishing

Material strength – Parts are dense and strong

Mass production – Ideal for large quantities

These features make MIM perfect for precision parts.

4. Why Choose Metal Injection Molding India?

India is now one of the top destinations for MIM. Indian companies are supplying parts to global markets. But what makes Metal Injection Molding India stand out?

Here’s what India offers:

Affordable manufacturing – Lower costs without compromising quality

Advanced facilities – Modern equipment and quality labs

Skilled engineers – Trained professionals with global experience

Wide material range – Stainless steel, titanium, copper, and more

Flexible orders – Suitable for both small and large batches

This makes India a trusted partner for companies seeking high-precision parts.

5. Types of Precision Parts Made in India

Indian MIM companies produce a wide range of precision parts. These parts are used across sectors and meet international standards.

Common Products Include:

Gears and pinions

Connectors and couplings

Medical clamps and surgical tips

Lock parts and hinges

Miniature brackets and housings

Fuel injector parts and nozzles

All these parts are made with tight tolerances and high repeatability.

6. Materials Used in MIM India for Precision Parts

The choice of material affects part strength, durability, and use. Indian manufacturers offer a variety of options.

Popular Materials:

316L Stainless Steel – Corrosion resistant, used in medical and food industry

17-4PH Stainless Steel – High strength, used in aerospace and defense

Titanium – Lightweight, used in implants and aviation

Tool Steels (M2, T15) – Used in wear parts and cutting tools

Copper Alloys – Good conductivity, used in electronics

These materials support diverse needs with consistent quality.

7. Quality Control and Certifications

Precision demands quality. Indian MIM companies follow strict testing and standards.

Quality Measures Include:

Dimensional checks with CMM (Coordinate Measuring Machines)

Surface finish inspections

Density and porosity checks

Microscopic analysis for grain structure

Common Certifications:

ISO 9001 – Quality management

ISO 13485 – For medical parts

IATF 16949 – For automotive parts

AS9100 – For aerospace components

This ensures that parts meet global quality requirements.

8. Cost and Delivery Benefits

India offers a cost advantage without lowering standards.

How You Save:

Lower labor and setup costs

Less material waste

No or minimal machining

Shorter time to market

Indian companies also offer fast production cycles, on-time shipping, and global logistics support.

9. Custom Design and Engineering Support

Many Indian MIM companies help with design too. This support ensures your parts are optimized for MIM production.

Design Services Include:

3D modeling and simulation

Design for MIM (DFM) guidance

Rapid prototyping

Tool and mold design

This helps reduce errors and speeds up the development process.

10. Growing Global Presence

Indian MIM companies are now exporting to Europe, USA, Japan, and other regions. Global brands trust Indian firms for reliable, high-precision components.

What Global Clients Get:

Trusted quality

Clear communication

Flexible order sizes

Competitive pricing

India is not just a low-cost hub—it is a value-driven manufacturing partner.

Conclusion

Metal Injection Molding India is helping industries worldwide get the precision parts they need. With modern tools, skilled teams, and high standards, Indian companies are producing small, complex, and accurate parts for a wide range of uses.

Whether you need tiny gears, surgical tools, or high-strength components, India has the ability to deliver. For companies looking for precision, reliability, and value, Metal Injection Molding in India is the smart choice.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.