Metalized Flexible Packaging Market Demand, Trends and Forecast 2024–2032

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

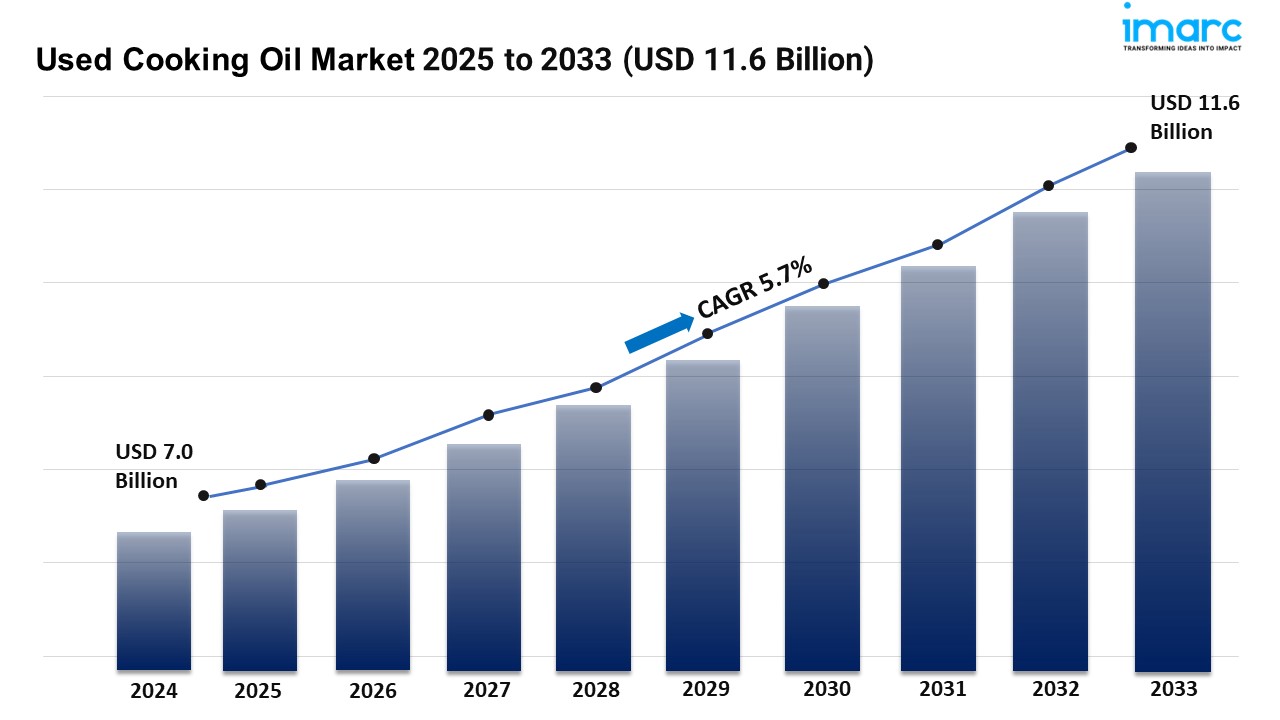

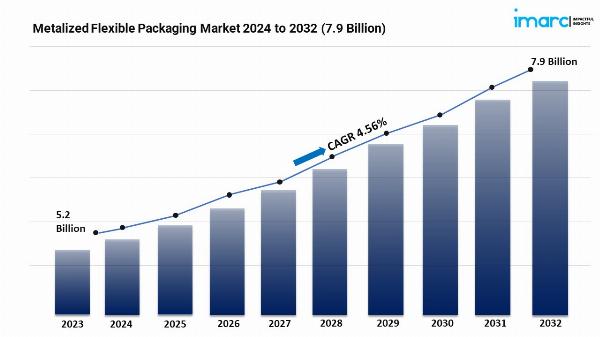

IMARC Group’s report titled “Metalized Flexible Packaging Market by Material Type (Aluminum Foil Based, Metalized Film), Packaging Type (Pouches, Bags, Roll Stock, Wraps, and Others), Application (Packaging, Decoration, Printing & Lamination, Labelling, Insulations), End Use Industry (Food, Beverages, Personal Care, Pharmaceuticals, Pet Food, and Others), and Region 2024–2032”. The global metalized flexible packaging market size reached US$ 5.2 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 7.9 Billion by 2032, exhibiting a growth rate (CAGR) of 4.56% during 2024–2032.

Grab a sample PDF of this report: https://www.imarcgroup.com/metalized-flexible-packaging-market/requestsample

Factors Affecting the Growth of the Metalized Flexible Packaging Industry:

● Increased Demand for Convenience:

The growing demand for metalized flexible packaging due to the increasing need for enhanced convenience among individuals is offering a favorable market outlook. Consumers are increasingly favoring portable and easy-to-use products. Metalized flexible packaging provides a lightweight and compact solution that enhances convenience and portability as compared to traditional rigid packaging. In addition, this type of packaging is often used for on-the-go products, such as snacks and beverages, which are in high demand among people with busy lifestyles and hectic schedules.

● Extended Shelf Life:

Metalized flexible packaging is highly valued for its superior barrier properties, which extend the shelf life of products by protecting them from moisture, oxygen, and light. This is particularly crucial for food and beverage items that require longer storage without compromising quality. Metalized packaging helps reduce waste and increase consumer satisfaction by maintaining product freshness and preventing spoilage. Its ability to preserve the integrity of sensitive products contributes to its widespread adoption across several industries. This extended shelf life not only benefits manufacturers but also offers consumers longer-lasting products.

● Sustainability Trends:

Sustainability trends are increasingly shaping the metalized flexible packaging market as both consumers and regulations prefer eco-friendly solutions. The growing focus on developing sustainable options that minimize environmental impact is offering a favorable market outlook. Moreover, innovations include using recyclable or biodegradable materials and improving recycling processes. As companies and consumers become more eco-conscious, the demand for sustainable packaging solutions rises. Furthermore, metalized flexible packaging that aligns with these sustainability goals helps manufacturers meet regulatory requirements and appeal to a wider consumer base.

Explore full report with table of contents: https://www.imarcgroup.com/metalized-flexible-packaging-market

Leading Companies Operating in the Global Metalized Flexible Packaging Industry:

- Amcor plc

- Celplast Metallized Products Limited

- Cosmo First Limited

- DUNMORE Corporation

- Huhtamäki Oyj

- Kendall Packaging Corporation

- Nissha Co. Ltd.

- Polyplex Corporation Limited

- Sonoco Products Company

- Transcontinental Inc.

- UFlex Limited

Metalized Flexible Packaging Market Report Segmentation:

By Material Type:

- Aluminum Foil Based

- Metalized Film

Aluminum foil based represents the largest segment as it has superior barrier properties.

By Packaging Type:

- Pouches

- Bags

- Roll Stock

- Wraps

- Others

Pouches hold the biggest market share due to increasing preferences for enhanced portability.

By Application:

- Packaging

- Decoration

- Printing & Lamination

- Labelling

- Insulations

Packaging accounts for the largest market share, which can be attributed to the rising focus on improved visual appeal.

By End Use Industry:

- Food

- Beverages

- Personal Care

- Pharmaceuticals

- Pet Food

- Others

Food exhibits a clear dominance in the market on account of the escalating need to preserve and extend the shelf life of products.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Europe enjoys a leading position in the metalized flexible packaging market, driven by the increasing focus on eco-friendly packaging.

Global Metalized Flexible Packaging Market Trends:

The growing demand for metalized flexible packaging due to the thriving food and beverage (F&B) industry is offering a favorable market outlook. Metalized flexible packaging offers an ideal solution for a wide range of products. It provides an effective barrier to maintaining product quality and freshness, which is crucial for packaged food items. Additionally, the convenience and versatility of flexible packaging align with increasing consumer preferences for ready-to-eat (RTE) and convenience food products.

Advancements assist in enhancing the functionality and appeal of metalized flexible packaging. Improved metalization processes, such as vacuum deposition and sputtering, provide better barrier properties and more durable packaging solutions.

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1–631–791–1145 | United Kingdom: +44–753–713–2163

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

![Solar Photovoltaic [PV] Market Share, Growth & Trends, 2025-2033](https://indibloghub.com/public/images/courses/682d9b9d5ec17902_1747819421.jpg)