New Product Launches Fuel Wellhead Components Market Expansion

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

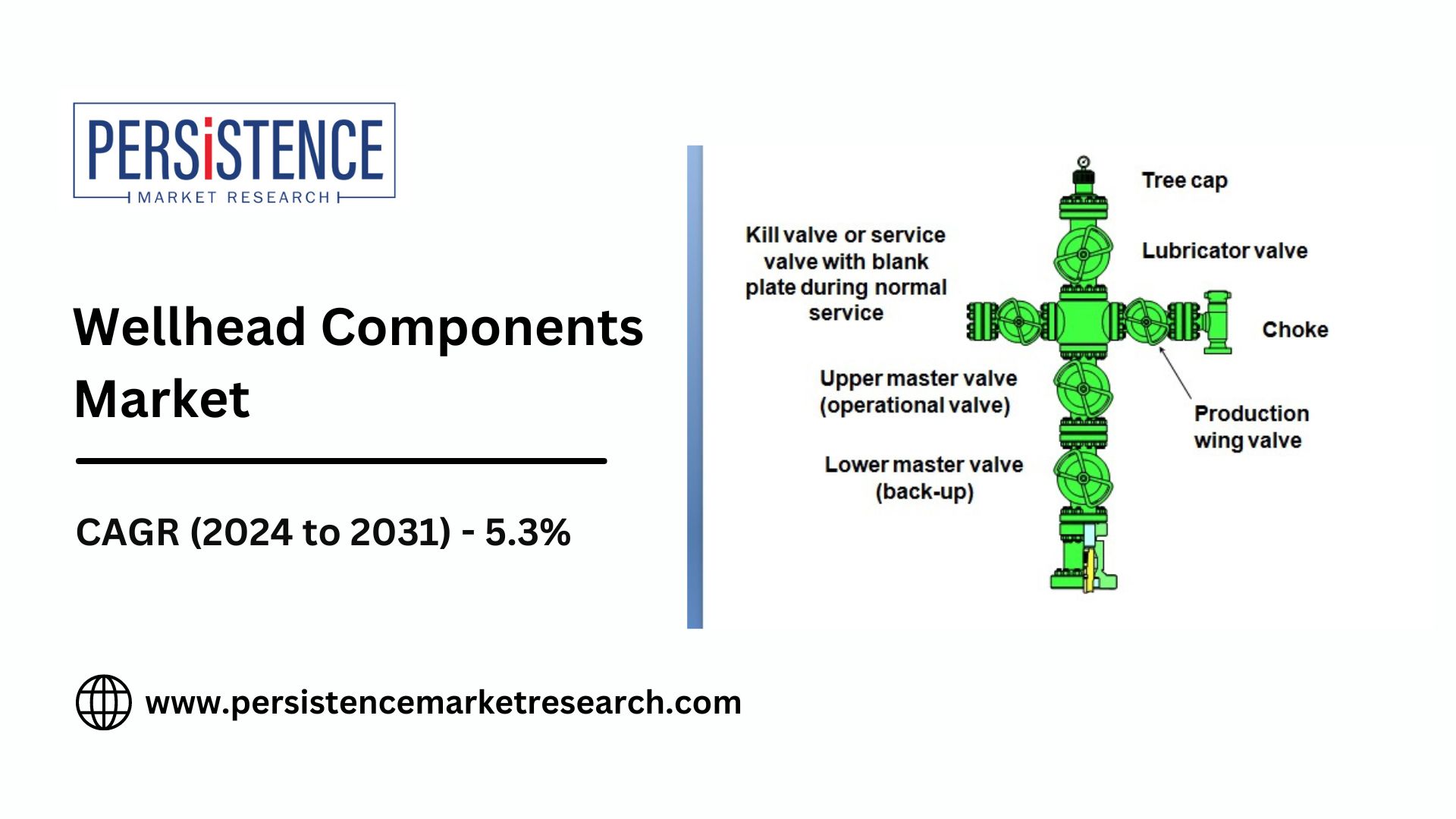

The wellhead components market is projected to grow from US$6.08 billion in 2024 to US$8.73 billion by 2031, with a compound annual growth rate (CAGR) of 5.3%. Key drivers of this growth include advancements in automation and digital technologies, which enhance wellhead performance and efficiency, and increased exploration and production activities in the oil and gas sectors. Significant opportunities are emerging in regions such as Asia Pacific, Latin America, and Africa. Onshore applications are expected to dominate the market, holding an 80% share. Additionally, the rising interest in unconventional oil and gas resources is driving demand for specialized wellhead equipment.

In the wellhead components market, new product launches are playing a crucial role in driving growth and expanding industry potential. With oil and gas companies continuously searching for innovative solutions to optimize efficiency, safety, and environmental compliance, manufacturers are responding by introducing new products designed to meet these demands. This article explores how cutting-edge technologies, environmentally conscious innovations, and customized components are shaping the market landscape through recent product launches.

1. Technological Advancements in Wellhead Components

In response to the complex demands of modern oil and gas extraction, companies are launching technologically advanced wellhead components that enhance productivity and safety.

Smart Wellhead Systems

Recent launches in smart wellhead systems are transforming traditional oil and gas operations. These systems are equipped with digital capabilities such as remote monitoring, data analytics, and automation, enabling operators to monitor and control operations in real time. Smart wellhead components allow companies to reduce the need for on-site personnel, minimizing risks and operational costs, especially in remote or hazardous locations.Enhanced Sealing and Pressure Management

Manufacturers are also developing components with enhanced sealing and pressure management capabilities, aimed at high-pressure, high-temperature (HPHT) wells. These components provide the reliability needed to maintain control over well conditions and mitigate risks in extreme environments. Recent products include advanced blowout preventers and sealing systems that reduce the chances of leaks, contributing to a safer and more controlled extraction process.

2. Environmentally Conscious Innovations

With a heightened focus on environmental responsibility, new product launches are increasingly designed to reduce environmental impact, a priority for operators and manufacturers alike.

Low-Emission Wellhead Components

Innovations in low-emission components are reshaping the market, as companies prioritize reducing greenhouse gas emissions. Some of the latest products feature materials and coatings that minimize emissions released during extraction. By meeting or exceeding environmental standards, these components are appealing to companies aiming for more sustainable operations, especially in regions with stringent regulations like Europe.Waste-Reducing Materials

Manufacturers are also experimenting with new materials and design processes that reduce waste. For example, recyclable and reusable components are being introduced to reduce the need for single-use parts, which often end up in landfills. Components that are easier to recycle and repurpose are highly desirable for environmentally conscious operators and can lower long-term operational costs by reducing material waste.

3. Customized Wellhead Components for Specific Applications

Recognizing the diverse needs of operators working in unique environments, companies are launching customized wellhead components tailored to specific applications, such as offshore platforms, HPHT wells, and unconventional resources.

Specialized Offshore Wellhead Components

Offshore environments present unique challenges, requiring components that can withstand corrosion, high-pressure conditions, and extreme weather. Recently launched wellhead components designed specifically for offshore applications focus on corrosion resistance, extended durability, and easy installation. These products support operators in efficiently managing offshore operations, reducing maintenance needs, and enhancing safety standards.HPHT-Optimized Components

As the oil and gas industry explores HPHT fields, manufacturers are launching components specifically designed to endure these conditions. Components like packers, flanges, and pressure-control valves are being engineered to function reliably under extreme pressures and temperatures, ensuring that operators have the appropriate tools to manage the demanding conditions of HPHT wells. Customizing products for these environments not only improves operational success but also reduces risks associated with high-pressure extraction.

4. Digital and IoT-Enabled Innovations in Product Launches

Digitalization has taken center stage in the wellhead components market, with companies introducing IoT-enabled products that support a data-driven approach to oil and gas operations.

Connected Wellhead Components

IoT-enabled wellhead components represent a significant shift toward digitalization in the industry. These connected components, such as pressure and temperature sensors, transmit real-time data to operators, allowing for immediate response to changing well conditions. New launches in IoT-enabled components also support predictive maintenance, which helps companies identify potential issues before they escalate, minimizing downtime and optimizing operational efficiency.Advanced Monitoring Systems

Monitoring systems integrated with AI and machine learning are becoming a popular feature in newly launched wellhead components. These systems analyze data from multiple components, providing operators with actionable insights that improve decision-making and enhance overall well integrity. By leveraging advanced monitoring, companies can reduce risks, improve safety, and achieve better performance metrics in complex operations.

5. Enhanced Safety Features in New Wellhead Components

Safety remains a top priority in the oil and gas sector, and new product launches are incorporating cutting-edge safety features that support secure and reliable operations.

Improved Blowout Prevention Technologies

Blowouts are a significant risk in oil and gas operations, and wellhead manufacturers are prioritizing safety by developing more effective blowout prevention systems. These advanced systems provide faster response times and improved pressure control, making them essential components for ensuring well integrity and operator safety. Recent launches focus on materials and mechanisms that withstand extreme pressure surges, significantly reducing the likelihood of blowouts.Fire-Resistant and Explosion-Proof Components

With heightened safety concerns, companies are introducing wellhead components that are fire-resistant and explosion-proof. These products are especially valuable for applications in volatile environments where any breach in equipment integrity could lead to catastrophic consequences. By utilizing specialized materials and designs, these components offer an added layer of protection against accidents, supporting safer operations in high-risk settings.

6. Expansion of Product Portfolios by Major Players

Leading companies are continually expanding their product portfolios with new wellhead component launches to cater to a broader range of applications and enhance market reach.

Diverse Product Offerings for Comprehensive Solutions

To address the varying needs of operators worldwide, key players are introducing a wide array of wellhead components that provide comprehensive solutions. For instance, some companies are focusing on providing a full suite of components, from basic wellhead parts to complex control systems, ensuring clients have access to all the equipment they need for effective well operations. This approach not only boosts the companies’ market presence but also positions them as one-stop solution providers.Focus on Modular and Scalable Components

Modularity and scalability are important trends in the market, as operators look for components that can be adjusted to meet the needs of different well sizes and operational scales. New modular wellhead components allow operators to scale operations up or down efficiently, offering flexibility that is crucial for managing both large and small projects. This versatility is appealing to operators who manage multiple well sites with varied demands.

Conclusion: New Product Launches Driving Market Momentum

The wellhead components market is thriving due to the influx of new products that address critical industry needs. From digital innovations and safety enhancements to environmentally friendly components and customized solutions, recent launches are enabling oil and gas operators to enhance productivity, safety, and sustainability. These advancements underscore the competitive nature of the market, as key players continuously push boundaries to meet the diverse needs of an evolving energy landscape. With ongoing technological progress and a steady focus on market-specific demands, the wellhead components market is poised for sustained growth, fueled by innovative product introductions that redefine industry standards.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.