Newsletter Copywriting – Emails That Convert, Not Bore!

Newsletter Copywriting – Emails That Convert, Not Bore!

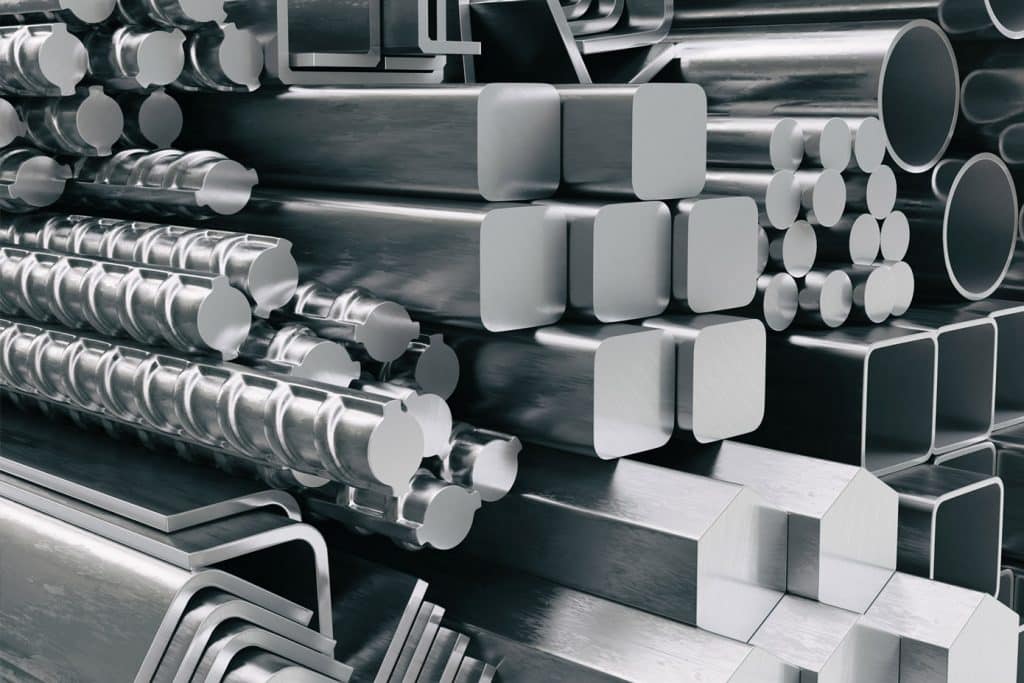

Nickel Alloys Market Growth Opportunities in Aerospace and Energy Sectors

Written by Neha Patil » Updated on: June 17th, 2025

The nickel alloys market is poised for significant growth, driven by the expanding needs of the aerospace and energy sectors. These sectors demand materials that offer superior strength, high-temperature resistance, and exceptional durability, making nickel alloys indispensable. As industries innovate and adopt advanced technologies, the market for nickel alloys is experiencing accelerated growth. This article explores the key opportunities fueling this expansion within the aerospace and energy industries.

For More Industry Insight: https://www.fairfieldmarketresearch.com/report/nickel-alloys-market

1. Nickel Alloys in Aerospace: Meeting High-Performance Needs

The aerospace sector has long relied on nickel alloys for their unmatched ability to perform in extreme environments. As the global aviation industry rebounds post-pandemic and space exploration initiatives intensify, the demand for nickel alloys is set to surge.

Key Aerospace Applications

Jet Engines: Nickel alloys are essential in jet engines due to their ability to withstand extreme temperatures, ensuring efficient operation and longevity.

Turbine Blades: These components require materials that resist heat and mechanical stress, making nickel alloys a critical choice.

Spacecraft Components: Reusable spacecraft and interplanetary missions rely on nickel alloys for their durability in vacuum and radiation-heavy environments.

Growth Drivers

Global Air Travel Recovery: The resurgence in passenger air travel has led to increased aircraft production, driving the need for high-performance materials.

Space Exploration: Investments in space programs and commercial space travel are fueling demand for nickel alloys in rocket engines and structural components.

Lightweight Design Trends: The aerospace industry’s focus on reducing weight for fuel efficiency makes nickel alloys a preferred choice due to their strength-to-weight ratio.

2. Energy Sector: Transforming with Nickel Alloys

The energy sector’s transition toward renewable energy and advanced power systems presents a lucrative opportunity for the nickel alloys market. Their corrosion resistance and high-temperature tolerance make them ideal for demanding energy applications.

Renewable Energy Applications

Wind Turbines: Nickel alloys enhance the durability of turbine components, particularly in offshore wind farms exposed to harsh conditions.

Hydrogen Production: Electrolysis systems for hydrogen generation rely on nickel alloys to resist chemical wear and corrosion.

Energy Storage: Nickel-rich cathodes in lithium-ion batteries improve energy density and lifespan, supporting renewable energy storage solutions.

Oil and Gas Sector

Despite the push for cleaner energy, the oil and gas industry remains a key consumer of nickel alloys:

Pipelines and Drilling Equipment: Nickel alloys’ resistance to high-pressure and corrosive environments ensures reliable operations in subsea and offshore applications.

Heat Exchangers: Used in refining processes, these components benefit from nickel alloys’ ability to withstand extreme temperatures and chemical exposure.

Growth Drivers

Clean Energy Transition: Governments worldwide are investing in wind, solar, and hydrogen energy systems, creating substantial demand for nickel alloys.

Battery Technology Advancements: The proliferation of electric vehicles (EVs) and renewable energy projects drives innovation in nickel-rich battery components.

Aging Infrastructure: Upgrading energy systems with advanced materials like nickel alloys is essential for improving efficiency and sustainability.

3. Technological Advancements: Unlocking New Opportunities

The development of additive manufacturing (3D printing) and advanced recycling technologies is reshaping the nickel alloys market, particularly in aerospace and energy.

Additive Manufacturing

Complex Components: 3D printing enables the production of intricate nickel alloy parts for jet engines, turbines, and other critical applications.

Material Efficiency: By reducing waste, additive manufacturing lowers costs and supports sustainable practices.

Customization: Aerospace and energy systems benefit from tailored solutions that improve performance and efficiency.

Recycling and Sustainability

Nickel Recycling: Innovations in recycling technologies are addressing environmental concerns and reducing raw material costs.

Sustainable Production: Energy-efficient refining and alloying methods are gaining traction, aligning with industry sustainability goals.

4. Regional Growth Insights

Asia Pacific: A Powerhouse for Nickel Alloy Demand

Asia Pacific is the leading market for nickel alloys, driven by rapid industrialization and infrastructure development in countries like China and India.

Aerospace Growth: Rising air travel demand and domestic aircraft production fuel the need for nickel alloys.

Energy Investments: China’s focus on renewable energy and India’s expanding wind and solar capacity contribute to robust market growth.

EV Manufacturing: The region’s dominance in electric vehicle production boosts the demand for nickel-rich battery materials.

North America: Advancing Technologies

North America remains a lucrative market due to:

Space Exploration Programs: Investments in NASA and private aerospace companies are driving demand for advanced materials.

Energy Innovations: The U.S. energy sector’s focus on hydrogen and wind energy systems is spurring the adoption of nickel alloys.

Europe: Sustainability at the Core

Europe’s emphasis on green energy and sustainable transportation supports nickel alloy usage in renewable energy systems and electric vehicles.

5. Challenges and Mitigation Strategies

While the opportunities are vast, the nickel alloys market faces challenges, including:

High Production Costs: Nickel extraction and refining are resource-intensive processes. Solution: Innovations in recycling and production efficiency are helping reduce costs.

Complex Machinability: Nickel alloys are difficult to machine due to their high strength. Solution: Advanced manufacturing techniques and tool technologies are mitigating these challenges.

Supply Chain Vulnerabilities: Dependence on nickel from specific regions creates supply risks. Solution: Diversifying supply chains and investing in domestic production can address these issues.

6. Future Outlook for Nickel Alloys

The aerospace and energy sectors will remain key growth drivers for the nickel alloys market in the coming years. Emerging trends such as the proliferation of electric vehicles, advancements in hydrogen energy, and space exploration programs will redefine demand dynamics. Innovations in additive manufacturing, sustainable production practices, and recycling technologies will further enhance the market’s potential.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.