Precision Bearings: The Ultimate Guide to High-Accuracy Bearings

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Precision bearings are essential components in applications that require high accuracy, low friction, and reliable performance. They are designed to provide exceptional rotational accuracy and stability, making them ideal for machinery and equipment where even the slightest deviation can affect the overall operation. This guide covers what precision bearings are, their types, applications, benefits, and how to choose the right precision bearing for your needs.

What Are Precision Bearings?

Precision bearings are a type of rolling-element bearing designed to offer high performance in terms of rotational accuracy, speed, and load-bearing capacity. They are engineered to tighter tolerances compared to standard bearings, ensuring consistent performance under demanding conditions. Precision bearings are used in industries like aerospace, medical, robotics, and automotive, where precision and reliability are crucial.

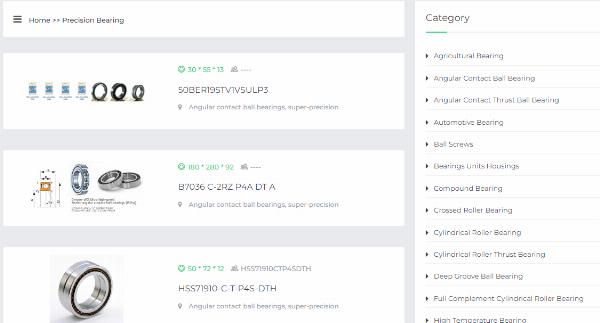

Types of Precision Bearings

Angular Contact Ball Bearings

Description: These bearings are designed to support both radial and axial loads. The raceways of the inner and outer rings are offset relative to each other, allowing for high-speed and high-precision applications.

Applications: CNC machines, high-speed spindles, precision gearboxes.

Cylindrical Roller Bearings

Description: These bearings feature cylindrical rollers that provide a larger contact area, allowing for higher load capacities and precise radial support.

Applications: High-speed machine tools, robotics, and industrial automation.

Tapered Roller Bearings

Description: With conical inner and outer ring raceways and tapered rollers, these bearings handle both radial and axial loads, providing excellent precision and load-bearing capabilities.

Applications: Automotive wheel hubs, high-precision gears, and industrial machinery.

Spherical Roller Bearings

Description: These bearings accommodate misalignment and provide high load capacity, making them suitable for applications requiring both precision and robustness.

Applications: Heavy machinery, mining equipment, and paper mills.

Thrust Bearings

Description: Designed to handle axial loads, thrust bearings can be ball or roller-type, providing high precision and load-bearing capacity for axial loads.

Applications: Turntables, rotary tables, and precision indexing tables.

Hybrid Ceramic Bearings

Description: These bearings use ceramic balls and steel rings, offering lower friction, higher speeds, and longer life compared to traditional steel bearings.

Applications: High-speed spindles, aerospace components, medical devices.

Key Features of Precision Bearings

High Rotational Accuracy: Precision bearings are manufactured to tight tolerances, ensuring minimal deviation in rotational movement.

High Speed: They are capable of operating at higher speeds with reduced friction and heat generation.

Low Noise and Vibration: Essential for applications where smooth and quiet operation is required.

Long Service Life: Made from high-quality materials, precision bearings offer longer service life, reducing maintenance needs.

High Load Capacity: They can support a combination of radial and axial loads, providing flexibility in various applications.

Applications of Precision Bearings

Precision bearings are vital in industries where accuracy, speed, and reliability are crucial:

Machine Tools: Precision bearings are used in the spindles of CNC machines, lathes, and milling machines to ensure accurate and smooth operation.

Aerospace: They are used in aircraft engines, landing gear, and other critical components where reliability and precision are paramount.

Medical Equipment: Precision bearings are employed in MRI machines, surgical robots, and dental equipment for their high accuracy and smooth operation.

Robotics and Automation: In robotic arms and automated assembly lines, precision bearings enable smooth and precise movements.

Automotive: High-precision bearings are used in transmissions, wheel hubs, and electric motors to enhance performance and efficiency.

Benefits of Using Precision Bearings

Improved Accuracy: Precision bearings reduce errors and deviations, ensuring high-accuracy performance in critical applications.

Enhanced Performance: With low friction and high-speed capabilities, they boost the overall performance of machinery.

Reduced Maintenance: Precision bearings are designed for durability and longevity, reducing the need for frequent replacements.

Increased Productivity: By ensuring smooth and efficient operation, precision bearings help increase productivity in manufacturing and automation processes.

How to Choose the Right Precision Bearing

Application Requirements: Consider the specific requirements of your application, including load type (radial, axial, or combined), speed, and environmental conditions.

Bearing Type: Select the bearing type that matches your application needs. For example, choose angular contact bearings for high-speed spindles or cylindrical roller bearings for heavy radial loads.

Load Capacity: Ensure the bearing can support the required loads without compromising performance.

Speed: Choose a bearing with a speed rating that matches or exceeds your application's operational speed.

Lubrication: Proper lubrication is crucial for bearing performance and longevity. Choose bearings that offer suitable lubrication options for your application.

Material: Select bearings made from high-quality materials like steel or ceramic to ensure durability and optimal performance.

Precision Grade: Bearings come in various precision grades (e.g., P0, P6, P5, P4). Higher grades (e.g., P4) offer better accuracy and performance but may come at a higher cost.

Where to Buy Precision Bearings?

For high-quality precision bearings, Tradebearings is a reliable source. They offer a wide range of precision bearings from top manufacturers, ensuring high performance, durability, and accuracy. Whether you need angular contact ball bearings, cylindrical roller bearings, or other types of precision bearings, Tradebearings provides competitive prices and expert support to help you find the perfect fit for your application.

Conclusion

Precision bearings are vital components in many industries, offering the high accuracy, speed, and reliability needed for demanding applications. By understanding the different types of precision bearings and their applications, you can select the right bearing to enhance the performance and longevity of your machinery. When it comes to purchasing precision bearings, Tradebearings stands out as a trusted supplier, offering a diverse selection and expert guidance.

If you need more detailed advice or assistance in selecting the right precision bearing for your application, feel free to reach out to Tradebearings for expert support. Visit more at https://en.tradebearings.com/list_33.html

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.