White Hat Link Building – Safe. Powerful. Long-Term.

White Hat Link Building – Safe. Powerful. Long-Term.

Precision in Packaging: Advanced Tube Filler Technologies for Modern Industries

Written by jigar » Updated on: June 17th, 2025

Introduction to the Tube Filler Market

The Tube Filler Market is a dynamic segment within the packaging industry, recognized for its specialized technology designed to efficiently fill products into tubes. Originating in the early 20th century, the development of tube fillers responded to the growing needs of the cosmetics, pharmaceuticals, and consumer goods sectors, which sought automated solutions to enhance packaging speed and reliability. The evolution of these machines from basic manual mechanisms to sophisticated automated systems illustrates the industry's adaptation to increasing global demands for precision and efficiency

Evolution of the Tube Filler Market

Tube filling technology began with simple, manual devices that required significant human intervention. As market demands grew, there was a clear shift towards automation. The mid-20th century saw the introduction of semi-automatic tube fillers, which improved the consistency and speed of the filling process. The transition didn't stop there; the digital era ushered in fully automatic tube fillers equipped with advanced controls, programmable logic controllers (PLC), and precise servo motors. These innovations allowed for enhanced accuracy, faster production times, and the ability to handle a wider range of materials and tube sizes.

Why Use Tube Fillers?

The rationale for employing tube fillers in manufacturing processes is multifaceted. Primarily, these machines offer unparalleled efficiency, significantly speeding up the packaging process while ensuring consistent product quality. Modern tube fillers are capable of handling various viscosities and types of products, from thick pastes and creams to fluid gels, making them indispensable in diverse industries. Moreover, the latest models feature enhanced automation, such as auto-feed systems and multiple filling heads, which minimize downtime and maximize output, effectively reducing operational costs and increasing production capacity.

Leading Manufacturers of Tube Fillers

The global landscape of the Tube Filler Market is dominated by several key manufacturing hubs. Cities like Munich, Milan, and Shanghai have emerged as leaders due to their technological advancements in machinery manufacturing. These regions boast a combination of experienced labor forces, innovative engineering practices, and a robust industrial infrastructure, making them attractive locations for leading companies in the tube filling industry. The presence of these manufacturing giants not only drives local economies but also sets global standards for tube filling technology.

Tube Filler Market by Type

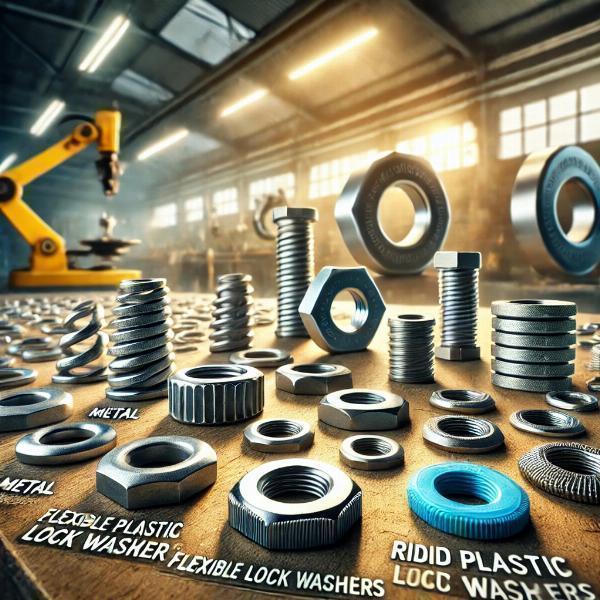

Segmentation in the Tube Filler Market is primarily based on the construction materials of the machines, which include Flexible Plastic, Rigid Plastic, Metal, and others. Each material caters to different needs within the market. Metal tube fillers, for example, are praised for their durability and robustness, ideal for high-volume, industrial environments. On the other hand, Rigid Plastic tube fillers provide a cost-effective yet efficient alternative for operations that require less intensive use and benefit from the lightweight nature of plastic.

Tube Filler Market by Application

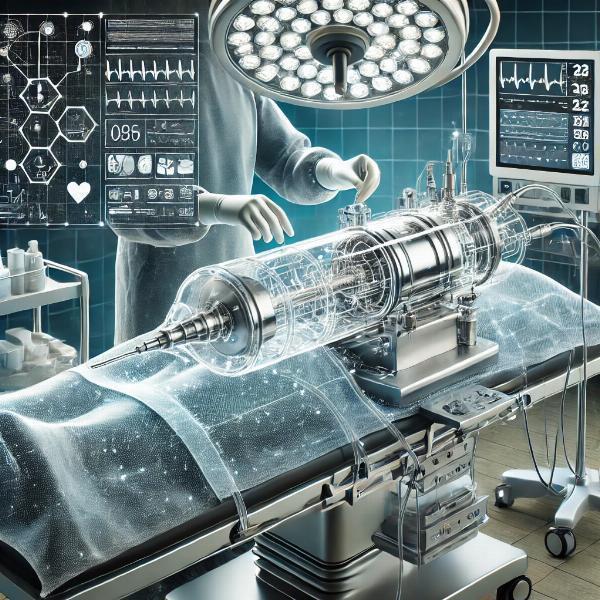

The application spectrum of tube fillers is broad, with significant use in sectors requiring stringent standards of hygiene and operational precision. The pharmaceutical, cosmetic, and food industries utilize these machines for their ability to accurately fill products while maintaining strict cleanliness. Tube fillers excel in packaging everything from medicinal creams and topical ointments to cosmetic lotions and food pastes, ensuring that they are not only filled at optimal speeds but also securely sealed to preserve freshness and prevent contamination.

Conclusion: Future Growth Prospects of the Tube Filler Market

Looking forward, the prospects for the Tube Filler Market are robust, driven by several key factors poised to fuel its expansion over the next five years. The continuous rise in global consumer demand for products packaged in tubes, such as toothpaste, beauty products, and condiments, ensures ongoing reliance on efficient filling technologies. Additionally, sustainability concerns are prompting innovations aimed at reducing the environmental impact of production processes, spurring the development of greener, more energy-efficient machines.

Technological advancements will further define the future trajectory of the Tube Filler Market. Integration of IoT and AI technologies is set to revolutionize production lines, enabling smarter, more responsive operations that can adapt to changing conditions and demands instantaneously. These advancements are anticipated to enhance the precision, speed, and flexibility of tube filling operations, making processes even more cost-effective and efficient.

In conclusion, the Tube Filler Market is at a pivotal juncture, where its growth is not just anticipated but inevitable. As industries continue to seek more innovative and efficient solutions for packaging, the role of tube fillers becomes increasingly critical. With ongoing advancements and a shift towards sustainable practices, the Tube Filler Market is well-positioned to meet the future needs of a diverse array of industries, ensuring its place as a key player in the global manufacturing landscape for years to come.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.