Revolutionizing Precision: The Rise of Robotics in the Italy CNC Drilling Machine Market

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

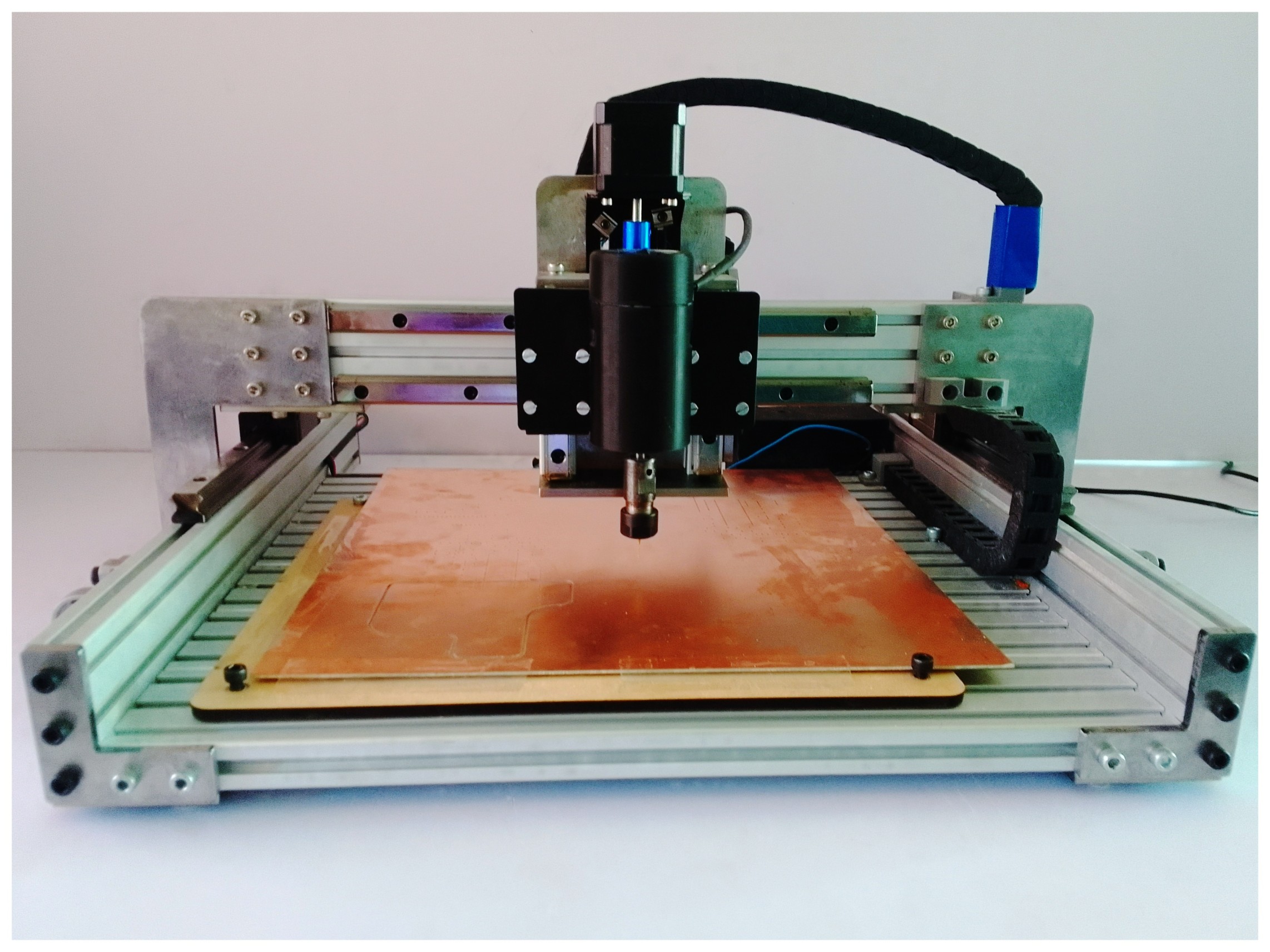

The Italy CNC Drilling Machine Market is undergoing a significant transformation, driven by the rapid integration of robotics into manufacturing processes. As industries evolve to meet the demands for higher productivity, precision, and safety, CNC (Computer Numerical Control) drilling machines enhanced with robotic automation are setting new standards in industrial efficiency. From the automotive sector to aerospace manufacturing, Italy is at the forefront of this cutting-edge technological shift.

Download Free Sample

Overview of the CNC Drilling Machine Market in Italy

Italy has long been recognized as a key player in the European manufacturing landscape, with a well-established presence in sectors such as automotive, aerospace, and precision engineering. CNC drilling machines, essential for producing complex parts with high accuracy, are a staple in many of these industries.

In recent years, the Italian market has seen an upsurge in demand for more advanced and automated machinery. This demand is fueled by a combination of factors, including labor shortages, rising costs, and the need for consistent quality in high-volume production. As a result, manufacturers are increasingly turning to CNC drilling machines with robotic integration to stay competitive.

Inquire Before Buying

The Role of Robotics in Modern CNC Drilling

Robotics is no longer a futuristic concept in Italian factories—it’s a current reality reshaping the operational landscape. In CNC drilling, robots play an integral role in enhancing automation, improving precision, and reducing manual labor. Here’s how:

1. Automated Loading and Unloading

Robots efficiently handle the loading and unloading of workpieces, significantly reducing downtime between drilling cycles. This not only improves throughput but also minimizes the risk of human error or injury during the handling of heavy or delicate parts.

2. Precision and Consistency

Robotic arms are capable of executing intricate and repetitive movements with extreme accuracy. This ensures a higher level of consistency in drilled parts, which is especially crucial in industries like aerospace and automotive where tolerances are extremely tight.

3. Reduced Workplace Hazards

By taking over potentially dangerous tasks, such as operating close to high-speed rotating tools or handling sharp metal components, robots help reduce the likelihood of workplace accidents. This leads to a safer environment and fewer disruptions due to injury-related downtime.

4. Increased Flexibility

Modern robotic systems can be easily reprogrammed to handle different tasks or parts, offering manufacturers greater flexibility in adapting to changing production needs. This adaptability is particularly advantageous for small and medium enterprises (SMEs) in Italy that must stay agile in a competitive global market.

Key Sectors Driving Demand

Automotive Industry

Italy’s automotive sector is a major consumer of CNC drilling machines. Precision components like engine blocks, transmission parts, and suspension systems require meticulous drilling operations. Robotic integration enables faster cycle times and higher-quality output, which are critical in this high-volume, high-precision environment.

Aerospace and Defense

Aerospace manufacturing in Italy is growing, and the demand for lightweight, complex components made from advanced materials is increasing. CNC drilling machines, supported by robotic automation, ensure precise and consistent results, helping Italian firms meet stringent international standards.

General Manufacturing and SMEs

While large corporations are leading the charge, SMEs are also embracing robotic CNC systems to increase efficiency and scale operations. The availability of more affordable robotic solutions tailored to smaller operations is helping democratize access to this advanced technology.

Benefits of Robotic Integration in CNC Drilling

The advantages of incorporating robotics into CNC drilling machines extend beyond productivity:

Reduced Operational Costs: Less need for manual labor and fewer material defects lower overall costs.

Enhanced Product Quality: Robots minimize inconsistencies, ensuring parts meet exact specifications.

Scalability: Automation allows manufacturers to easily scale up production without sacrificing quality.

Real-Time Monitoring and Feedback: Integration with IoT and AI enables real-time data collection and predictive maintenance.

Challenges and Considerations

Despite its benefits, the integration of robotics into CNC drilling is not without challenges:

High Initial Investment: The upfront cost of robotic systems can be a barrier, especially for smaller firms.

Skilled Workforce Requirements: There’s a growing need for technicians and engineers skilled in both CNC programming and robotics.

Integration Complexity: Merging robotics with existing CNC setups can be technically challenging and may require substantial system redesign.

To overcome these hurdles, Italian manufacturers are increasingly partnering with technology providers and investing in workforce training initiatives.

Market Trends and Future Outlook

1. Growth of Collaborative Robots (Cobots)

Cobots are designed to work safely alongside human workers, making them ideal for smaller workshops. They are easier to program, require less space, and offer a cost-effective entry point into automation.

2. AI and Machine Learning Integration

AI is beginning to play a larger role in optimizing CNC drilling operations. Machine learning algorithms can analyze performance data to improve tool paths, reduce cycle times, and predict maintenance needs.

3. Sustainability and Energy Efficiency

With increasing environmental regulations and consumer awareness, energy-efficient CNC systems with robotic support are gaining traction. Robotics can help optimize resource use, minimize waste, and improve sustainability metrics.

4. Expansion of Export Markets

Italy’s expertise in precision manufacturing positions its CNC machine manufacturers to tap into export markets across Europe and beyond. Robotics-enhanced machines offer a competitive edge that appeals to international buyers looking for cutting-edge solutions.

Government Support and Industry Collaboration

The Italian government has implemented several initiatives under its “Industry 4.0” program to promote advanced manufacturing technologies. These include tax incentives, grants for digital innovation, and subsidies for workforce development. Such support is accelerating the adoption of robotics in the CNC sector.

Collaborations between academia, research institutions, and industry players are also playing a crucial role. Projects focused on innovation in mechatronics and robotics are driving the development of next-generation CNC systems in Italy.

Conclusion

The Italy CNC Drilling Machine Market is experiencing a technological renaissance fueled by the seamless integration of robotics. What once required manual precision and repetitive labor is now being reimagined with intelligent automation. This transformation is not only boosting productivity and quality but also redefining what’s possible in modern manufacturing. As Italian manufacturers continue to embrace robotic CNC drilling solutions, they are positioning themselves at the forefront of global innovation. The convergence of robotics, AI, and advanced machining is creating a smarter, safer, and more sustainable industrial future—one drill at a time.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.