Revolutionizing Precision Work with the Handheld Fiber Laser Welding and Cutting Machine

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

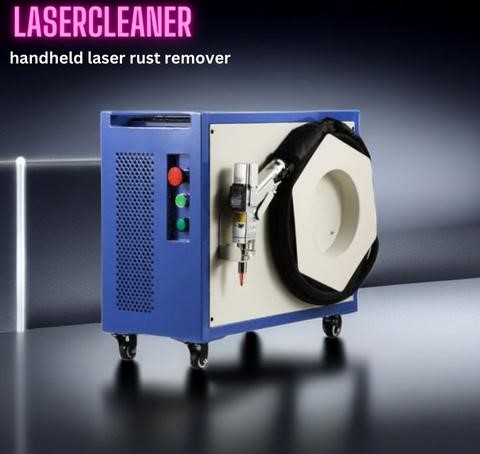

In the rapidly evolving landscape of modern manufacturing, precision, efficiency, and versatility are no longer optional—they're essential. One of the most groundbreaking tools that meet all three demands is the handheld fiber laser welding and cutting machine. This compact powerhouse is changing the way professionals in fabrication, automotive, electronics, and metalworking approach their craft.

Whether you're a workshop owner, a product developer, or part of an industrial production line, understanding how this technology works—and why it outperforms traditional tools—can elevate your operations to a new level of excellence.

What is a Handheld Fiber Laser Welding and Cutting Machine?

At its core, a handheld fiber laser welding and cutting machine combines the functionality of two industrial tools in one device: a laser welder and a laser cutter. Instead of bulky, stationary setups, this compact unit allows users to perform high-precision metal welding and cutting in a portable format.

Fiber laser technology uses a solid-state laser that is transmitted through a fiber optic cable, which increases efficiency, beam quality, and power output. When integrated into a handheld design, it provides a unique blend of mobility and power that traditional systems can't match.

Advantages That Set It Apart

Unmatched Precision and Quality

The laser beam’s precision ensures clean, smooth edges with minimal thermal distortion. This makes it ideal for delicate or high-value components that can’t afford rework or damage.

Time and Labor Efficiency

With speeds up to four times faster than traditional TIG or MIG welding, this system dramatically reduces production time. The ease of use also means fewer hours spent on setup and rework, and less dependence on highly skilled operators.

Portability with Industrial Strength

Unlike stationary units, handheld fiber laser systems can be easily moved around a shop floor or taken to on-site jobs. This mobility doesn't sacrifice power—many models are capable of welding metal up to several millimeters thick and cutting through sheets of steel, aluminum, and stainless steel.

Minimal Consumables and Maintenance

Traditional welding methods rely on filler materials, electrodes, and shielding gases. Fiber lasers reduce or eliminate these needs, resulting in lower operating costs and less downtime due to maintenance.

Safe and User-Friendly

Modern handheld units are designed with intuitive interfaces, safety interlocks, and training modes, making them accessible to beginners while still delivering professional-grade results.

Ideal Applications Across Industries

Automotive Repair and Customization

Fiber lasers allow for detailed bodywork repairs, frame cutting, and welding without distorting the metal or damaging adjacent components.

Metal Fabrication

Whether producing architectural metal panels, furniture, or custom brackets, the machine ensures high-quality seams and precise cuts.

Electronics and Aerospace

Delicate welding and micro-cutting tasks are executed with incredible precision, critical in high-tech sectors.

HVAC and Plumbing

Installers benefit from the machine’s portability when working in confined spaces, handling pipework, ducts, and fittings with clean, leak-proof welds.

Why Choose LaserChina?

When investing in industrial-grade equipment, reliability and support matter just as much as performance. LaserChina’s handheld fiber laser welding and cutting machine stands out not only for its robust technology but also for the unmatched customer service, global delivery options, and professional training support it offers.

LaserChina provides:

Tailored models for different power needs (ranging from 1000W to 3000W+)

Durable build quality backed by warranties

Smart integration with automation systems

Technical assistance and remote troubleshooting

With more than two decades in the laser technology industry, LaserChina is trusted by manufacturers worldwide for innovation, reliability, and affordability.

Final Thoughts

As competition in manufacturing intensifies, the need for smarter, faster, and more precise tools becomes critical. The handheld fiber laser welding and cutting machine from LaserChina is the all-in-one solution that empowers businesses to achieve higher productivity, better quality, and lower costs.

Whether you're scaling up production or adding versatility to your toolkit, this cutting-edge equipment is a game-changer. Explore the future of fabrication today with LaserChina and stay ahead in your industry.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.