Russia Injection Molding Machine Market: Trends, Challenges, and Environmental Impact

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

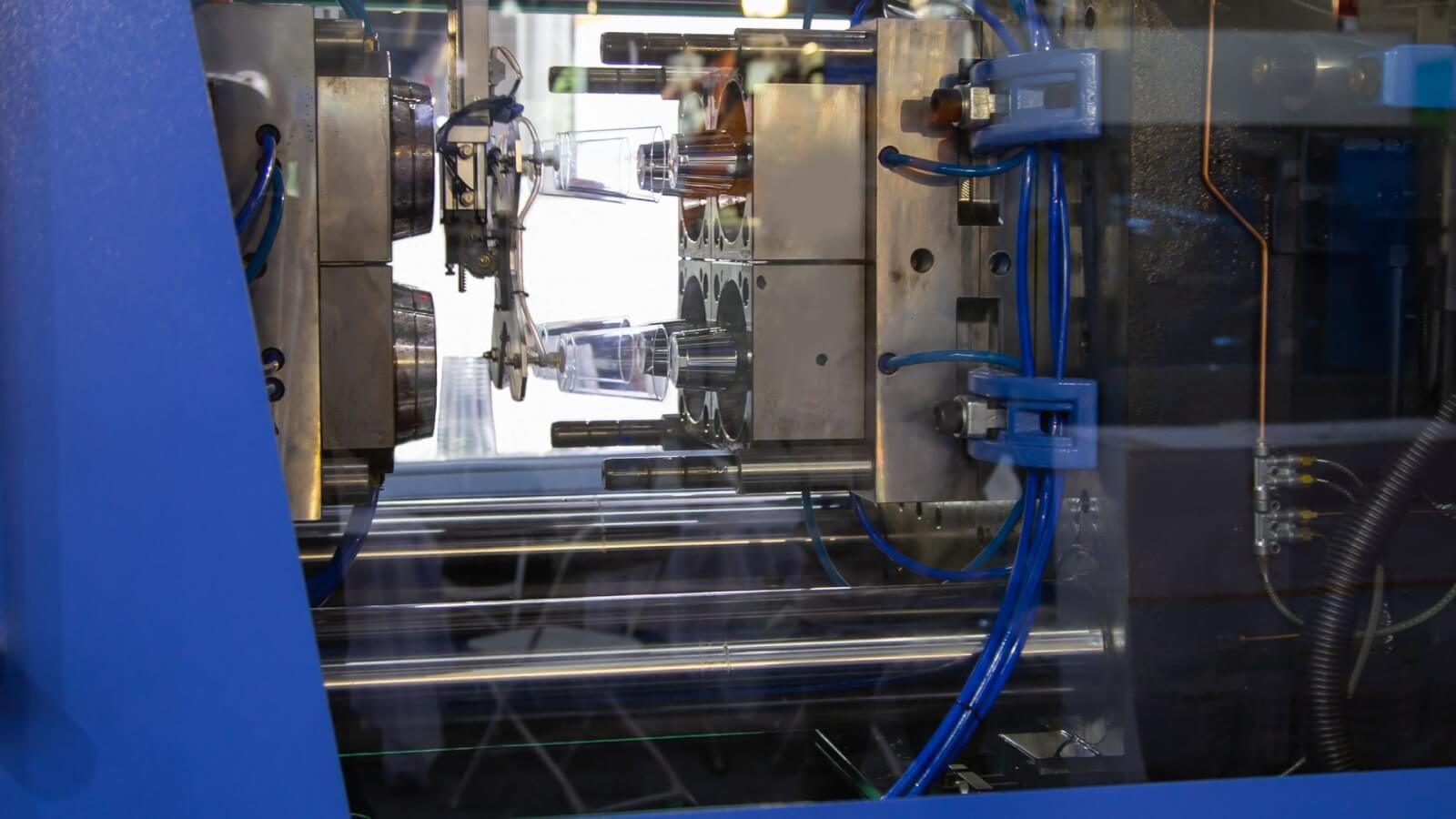

The Russia Injection Molding Machine Market has witnessed notable growth in recent years, driven by advancements in technology, rising industrial demand, and a diverse range of applications across various sectors. As manufacturers across industries look to optimize production processes, injection molding machines have become integral to the manufacturing of plastics and other materials. However, as the market evolves, environmental regulations and sustainability concerns have increasingly influenced the design, use, and manufacturing of these machines. This article delves into the Russia injection molding machine market, focusing on key market trends, challenges, and the impact of environmental regulations.

Click Here For FREE Sample!

Overview of the Russia Injection Molding Machine Market

Russia's injection molding machine market is diverse, driven by the automotive, packaging, electronics, and consumer goods sectors. These industries demand high-quality, cost-effective solutions for mass production, making injection molding machines indispensable. In recent years, Russia's manufacturing sector has expanded significantly, spurring demand for advanced IMM systems capable of producing high-precision parts in large quantities.

The Russian market is characterized by a mix of domestic and international players, with manufacturers increasingly adopting new technologies such as electric and hybrid injection molding machines. These machines offer enhanced precision, energy efficiency, and sustainability, which have become key factors driving growth in the sector. While traditional hydraulic machines are still widely used, the trend toward automation and energy-efficient systems is accelerating.

Market Trends Driving Growth

1.Technological Advancements in Injection Molding Machines

Technological innovation remains a key driver of growth in the Russian injection molding machine market. As the demand for high-precision, intricate parts increases, manufacturers are turning to machines equipped with advanced features such as multi-component injection, automated part handling, and integrated robotics. These technologies improve productivity, reduce human error, and allow for the production of more complex designs.

Electric injection molding machines, known for their energy efficiency and precise control, have gained popularity in Russia. These machines consume less energy compared to hydraulic models, reducing operational costs and helping manufacturers meet sustainability goals. Moreover, the global shift toward Industry 4.0 and automation has prompted an increasing adoption of smart, connected machines in the Russian market, enhancing production efficiency and reducing downtime.

2.Demand from Key Industries

The demand for injection molding machines in Russia is largely driven by industries such as automotive, packaging, and electronics. In the automotive sector, the growing demand for lightweight, durable components and parts made from advanced polymers has led to an increased adoption of injection molding technology. Similarly, the packaging industry, which requires high volumes of plastic products like bottles, containers, and caps, continues to be a major consumer of injection molding machines.

The electronics sector also requires precision injection molding machines to produce components such as housings, connectors, and other small, intricate parts. These industries drive significant demand for machines that can meet the high standards for quality, accuracy, and repeatability required in manufacturing.

Inquire Before Buying

3.Shift Toward Energy-Efficient Machines

As energy costs rise and sustainability becomes a priority, Russian manufacturers are increasingly opting for energy-efficient injection molding machines. Electric and hybrid machines have gained traction due to their lower energy consumption and reduced carbon footprint. These machines offer better precision and reduced cycle times, further enhancing their appeal to businesses seeking to improve profitability and minimize environmental impact.

Hybrid machines, which combine the best features of electric and hydraulic machines, are also becoming popular. These machines offer a balance between energy efficiency, speed, and the ability to produce high-quality parts, making them a versatile choice for various manufacturing applications.

Challenges Facing the Russia Injection Molding Machine Market

1.Economic Uncertainty

Russia's economy has faced challenges in recent years, including fluctuating oil prices, sanctions, and political instability. These factors have led to a level of uncertainty that affects both consumer demand and investment in new manufacturing technologies. While the injection molding machine market has continued to grow, the pace of expansion has been slower than in some other regions due to economic volatility.

Manufacturers in Russia must navigate these economic challenges while balancing the need for investment in advanced technologies with cost-control measures. Many companies are opting for refurbished or used injection molding machines to reduce capital expenditure, which can hinder the adoption of the latest technology.

2.High Import Dependence

Russia relies heavily on imports of advanced machinery, including injection molding machines. The country has limited domestic production capacity for high-end, specialized machines, leading to a dependency on foreign suppliers, primarily from Europe and Asia. This import reliance makes the Russian market vulnerable to fluctuations in international trade policies, supply chain disruptions, and foreign exchange rate volatility.

While there are efforts to bolster domestic manufacturing capabilities, the high import dependence remains a significant challenge for the injection molding machine market. Import tariffs and trade restrictions further complicate the procurement of new machines, which may hinder the growth of the market.

3.Skilled Labor Shortage

The demand for skilled labor in the injection molding sector remains a challenge in Russia. As the technology behind injection molding machines becomes more advanced, the need for highly trained engineers and machine operators increases. However, the availability of skilled workers is limited, which can result in higher labor costs and reduced operational efficiency.

Training programs and partnerships between manufacturers and educational institutions are critical to addressing this skills gap. Without a skilled workforce, Russian manufacturers may struggle to fully leverage the capabilities of modern injection molding machines, leading to inefficiencies and increased costs.

Environmental Regulations and Their Impact on Injection Molding Machines

Environmental regulations are becoming an increasingly important factor influencing the Russian injection molding machine market. Globally, governments are introducing stricter laws to reduce carbon emissions, improve energy efficiency, and minimize plastic waste. These regulations are influencing the way manufacturers approach production processes and how they design and use injection molding machines.

1.Energy Efficiency Standards

The Russian government, alongside international regulatory bodies, is setting stringent energy efficiency standards for manufacturing equipment. These standards are designed to reduce the carbon footprint of industrial operations and encourage the adoption of energy-efficient technologies. As a result, Russian manufacturers are increasingly turning to electric and hybrid injection molding machines, which offer significant energy savings compared to traditional hydraulic models.

Energy-efficient machines not only help companies comply with environmental regulations but also lead to cost savings through lower energy consumption. These machines also align with the global trend toward sustainability, helping companies improve their environmental footprint and appeal to eco-conscious consumers.

2.Waste Reduction and Recycling Regulations

In addition to energy efficiency, environmental regulations in Russia are focused on reducing plastic waste and promoting recycling. The government is introducing policies aimed at minimizing plastic pollution and encouraging manufacturers to use recyclable materials in production processes. This shift is encouraging manufacturers to invest in technologies that allow for better material usage and waste reduction in injection molding processes.

Injection molding machines capable of using recycled plastics and biodegradable materials are gaining popularity in Russia as a result. These machines help companies comply with the growing demand for sustainable production practices while reducing the environmental impact of their operations.

3.Sustainability and Corporate Social Responsibility (CSR)

Sustainability is becoming a critical factor in corporate decision-making. As Russian companies seek to improve their CSR profiles, many are investing in injection molding machines that align with sustainability goals. These machines offer not only energy efficiency and waste reduction but also the ability to use renewable and eco-friendly materials in the manufacturing process.

The adoption of sustainable practices is not only driven by regulatory pressure but also by consumer demand for environmentally friendly products. Companies that invest in green technologies can enhance their brand image and appeal to an environmentally conscious market, gaining a competitive advantage.

Conclusion

The Russia injection molding machine market is experiencing growth driven by technological advancements, rising demand from key industries, and a growing focus on energy efficiency and sustainability. While challenges such as economic uncertainty, import dependence, and labor shortages remain, manufacturers in Russia are increasingly adopting modern, energy-efficient machines that comply with stricter environmental regulations. These machines not only help businesses meet sustainability goals but also offer cost savings and improved productivity.

As environmental regulations continue to evolve, the Russian injection molding machine market will likely see further innovation, with manufacturers increasingly investing in sustainable technologies. The future of the market lies in the ability to balance technological advancements with environmental responsibility, ensuring that Russia remains competitive in the global manufacturing landscape while contributing to a more sustainable future.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.