Custom SEO Strategy – Your Path to Page #1 Starts Here!

Custom SEO Strategy – Your Path to Page #1 Starts Here!

Self-healing Materials Market Size, Revenue Share, Major Players, Growth Analysis, and Forecast 2032

Written by Joey Moore » Updated on: November 01st, 2024

Self-Healing Materials Industry Outlook 2024-2032

Summary:

- The global self-healing materials market size reached USD 2.6 Billion in 2023.

- The market is expected to reach USD 21.2 Billion by 2032, exhibiting a growth rate (CAGR) of 25.8% during 2024-2032.

- Europe leads the market, accounting for the largest self-healing materials market share.

- Concrete accounts for the majority of the market share in the type segment due to its widespread use in infrastructure projects, where enhanced durability and reduced maintenance costs are paramount.

- Intrinsic hold the largest share in the self-healing materials industry.

- Reversible polymers remain a dominant segment in the market, offering efficient and repeatable self-healing abilities that are critical in extending the life of various consumer and industrial products.

- Building and construction represents the leading end use industry segment.

- The increased demand for durability and rising safety standards are a primary driver of the self-healing materials market.

- Technological advancements and the development of more efficient healing mechanisms are reshaping the self-healing materials market.

Request a sample copy of the report: https://www.imarcgroup.com/self-healing-materials-market/requestsample

Industry Trends and Drivers:

- Increased Demand for Durability

Industries including aerospace, automotive, and construction consistently seek ways to enhance the lifespan of their products and infrastructures. Additionally, self-healing materials have emerged as a pivotal solution in these sectors due to their ability to autonomously mend themselves, thereby curtailing the frequency of repairs and extending product longevity. This intrinsic capability ensures sustained performance over extended periods and significantly slashes maintenance expenses. Moreover, the appeal of self-healing materials is particularly pronounced in environments where constant upkeep is challenging or costly. Consequently, as these materials evolve and their efficacy in real-world applications is proven, more industries are likely to adopt them to achieve better durability and reliability in their operations.

- Technological Advancements

The landscape of material science has witnessed profound transformations recently, with substantial enhancements in self-healing materials. These innovations span various dimensions, from the development of more efficient healing mechanisms to their integration into a broader spectrum of products. Additionally, modern self-healing materials can now be engineered to activate under specific environmental triggers such as changes in temperature or pressure, making them more versatile and effective. This capability broadens the practical applications of these materials and enhances their marketability. Moreover, various industries that once viewed the technology as nascent or unreliable are now increasingly confident in its integration into high-performance products, driven by demonstrable advancements and tangible benefits in operational contexts.

- Rising Safety Standards

As safety regulations tighten, particularly in the aerospace and automotive sectors, there is a growing mandate to adopt materials that contribute to safer operations and compliance with new standards. Additionally, self-healing materials are stepping into this role, offering a revolutionary approach to material maintenance. These materials significantly reduce the risk of catastrophic failures which can lead to accidents by automatically repairing cracks, wear, and other forms of structural damage. This capability is especially crucial in industries where the integrity of a material is fundamental to safety and operational efficacy. Furthermore, the adoption of self-healing technologies is becoming a strategic response to the increasing rigor of safety protocols, promising to enhance the safety and performance of products subjected to stringent regulatory environments.

Self-Healing Materials Market Report Segmentation:

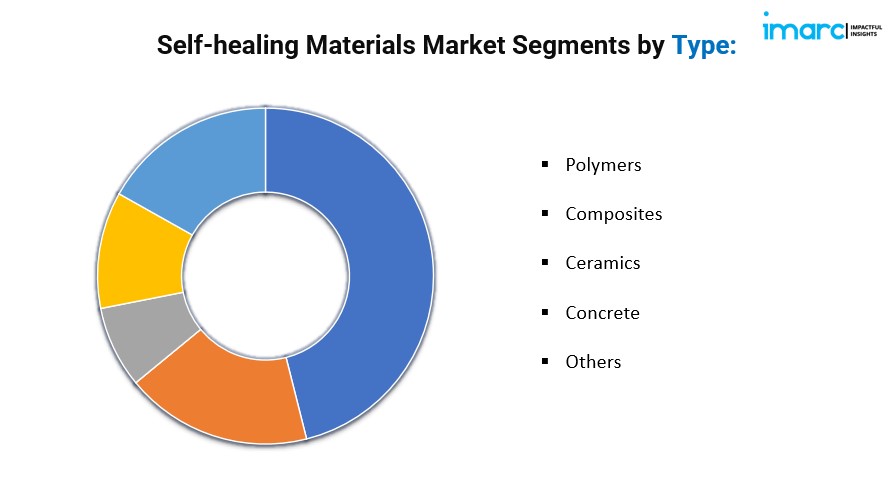

Breakup By Type:

- Polymers

- Composites

- Ceramics

- Concrete

- Others

Concrete represents the largest segment due to its widespread use in infrastructure projects, where enhanced durability and reduced maintenance costs are paramount.

Breakup By Form:

- Extrinsic

- Capsule-Based

- Vascular

- Intrinsic

Intrinsic accounts for the largest market share owing to its inherent capability to repair damage without external intervention, leading to longer material lifespans and fewer repairs.

Breakup By Technology:

- Reversible Polymers

- Microencapsulation

- Shape Memory Materials

- Biological Material Systems

- Others

Reversible polymers dominate the market growth, as they offer efficient and repeatable self-healing abilities that are critical in extending the life of various consumer and industrial products.

Breakup By End Use Industry:

- Building and Construction

- Healthcare

- Automotive

- Electrical and Electronics

- Aerospace

- Others

The building and construction industry hold the largest market share due to the growing demand for materials that can increase the longevity and safety of structures while minimizing repair costs.

Breakup By Region:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Europe hold the leading position owing to a large market for self-healing materials driven by stringent regulations promoting sustainability and innovation in advanced materials, coupled with significant investments in infrastructure development.

Top Self-Healing Materials Market Leaders:

The self-healing materials market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

- Applied Thin Films Inc.

- Arkema S.A.

- Autonomic Materials Inc.

- Avecom NV

- BASF SE

- Covestro AG

- High Impact Technology LLC

- Michelin North America Inc.

- NEI Corporation

- Sensor Coating Systems Ltd.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=5804&flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services. IMARC offerings include a thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Disclaimer: We do not promote, endorse, or advertise betting, gambling, casinos, or any related activities. Any engagement in such activities is at your own risk, and we hold no responsibility for any financial or personal losses incurred. Our platform is a publisher only and does not claim ownership of any content, links, or images unless explicitly stated. We do not create, verify, or guarantee the accuracy, legality, or originality of third-party content. Content may be contributed by guest authors or sponsored, and we assume no liability for its authenticity or any consequences arising from its use. If you believe any content or images infringe on your copyright, please contact us at [email protected] for immediate removal.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.