Semiconductor Etch Equipment Market: Growth, Trends, and Future Outlook

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

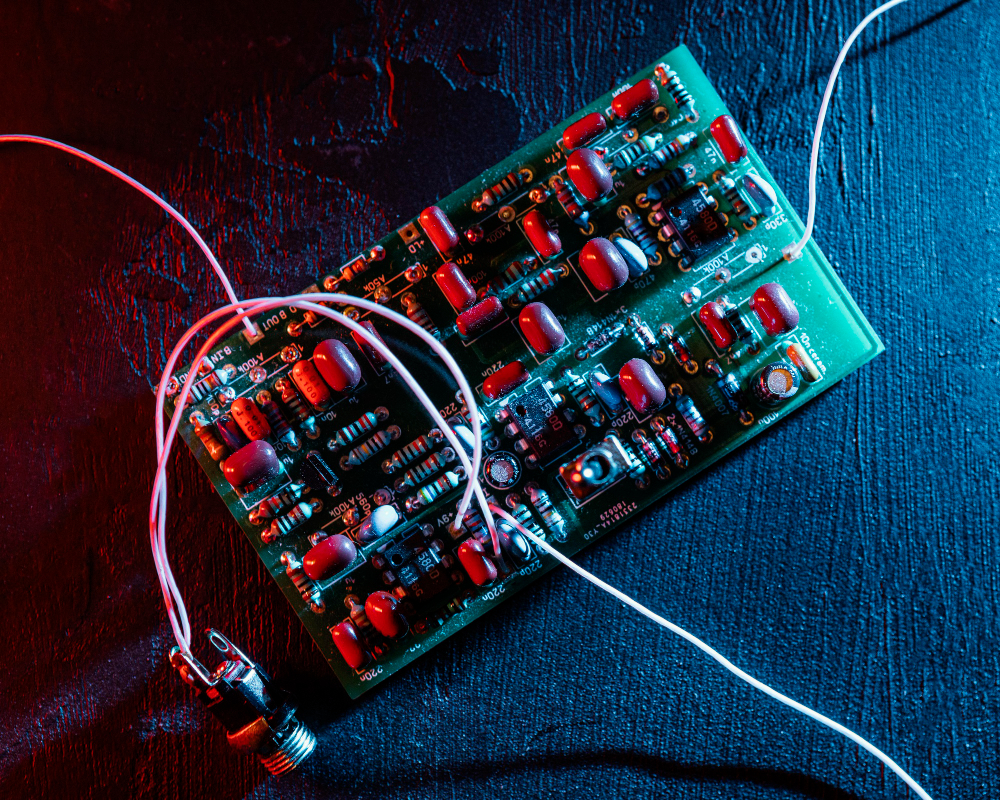

The Semiconductor Etch Equipment Market plays a pivotal role in the production of semiconductor devices, which are integral to nearly every modern technology. From consumer electronics to industrial machinery, the demand for smaller, faster, and more efficient semiconductors has led to a surge in the adoption of etching technology. The global semiconductor etch equipment market is set for significant growth, driven by advancements in semiconductor manufacturing processes, increased demand for consumer electronics, and the rise of emerging technologies like 5G and artificial intelligence (AI).

In this blog, we will explore the semiconductor etch equipment market, including its size, growth drivers, key segments, and the outlook for the future.

Market Overview

Current Market Size and Projections

The semiconductor etch equipment market was valued at approximately $10.54 million in 2023 and is projected to grow to $11.68 million by 2024. This growth is part of a broader trend of increasing demand for semiconductor devices and, by extension, the equipment used to manufacture them. Over the forecast period from 2024 to 2030, the market is expected to reach $20.18 million by 2030, representing a CAGR of 9.71%.

This strong growth is indicative of the increasing demand for semiconductor devices across various industries, as well as the continued innovation in etching technologies that enable the manufacturing of smaller, more advanced chips.

Key Market Drivers

Several factors are driving the growth of the semiconductor etch equipment market. These drivers are linked to the growing reliance on semiconductor-based devices and the advancements in semiconductor manufacturing technologies.

1. Growth in Semiconductor Demand

As semiconductor applications continue to expand across industries such as consumer electronics, automotive, telecommunications, and healthcare, the need for advanced etching equipment rises. From smartphones and computers to electric vehicles (EVs) and IoT devices, semiconductors are integral to the functioning of these technologies. As the demand for smaller, faster, and more efficient chips increases, semiconductor manufacturers need more sophisticated etch equipment to create increasingly complex circuits and structures.

2. Advancements in Semiconductor Manufacturing

Technological advancements in semiconductor manufacturing processes, such as miniaturization, are key drivers for the semiconductor etch equipment market. To produce chips with smaller features, manufacturers require advanced etching equipment that can etch precisely on smaller scales. Technologies like extreme ultraviolet (EUV) lithography and atomic layer etching (ALE) require highly specialized etch tools to ensure that manufacturers can achieve the necessary precision.

3. Emerging Technologies

The rise of emerging technologies such as 5G, AI, and machine learning is significantly increasing the demand for more powerful and efficient semiconductor devices. These technologies require high-performance chips that can handle massive data processing and communication tasks, thus fueling the demand for semiconductor manufacturing equipment, including etch tools. In particular, MEMS (Micro-Electro-Mechanical Systems) devices and power devices, which are essential for 5G infrastructure and AI systems, require precise etching processes to ensure reliability and functionality.

4. Increasing Investment in Semiconductor Manufacturing Facilities

As countries around the world ramp up efforts to boost domestic semiconductor production, investment in semiconductor manufacturing facilities is increasing. Governments and private enterprises are allocating more resources to semiconductor fabs (fabrication plants), creating significant opportunities for etch equipment manufacturers. These investments are driven by the need to reduce reliance on overseas semiconductor suppliers and ensure the availability of chips for various industries.

Key Market Segments

The semiconductor etch equipment market can be segmented by type and application. These segments help identify the areas where growth is most prominent and where companies can focus their research and development efforts.

1. By Type

Dry Etch Equipment: Dry etching is a key technology used in semiconductor manufacturing that involves the use of plasma or reactive gases to etch a pattern onto the surface of a semiconductor wafer. This technique is commonly used for creating small features in integrated circuits (ICs) and is widely employed in advanced semiconductor manufacturing processes. Dry etching provides high precision and is used in the production of logic devices, memory devices, and MEMS.

Wet Etch Equipment: Wet etching involves the use of liquid chemicals to remove layers from the wafer surface. It is typically used for etching metals, oxides, and other materials in the semiconductor fabrication process. While not as precise as dry etching, wet etching is effective for certain processes where high etching rates are needed. Wet etch equipment is commonly used in MEMS fabrication, power devices, and other applications where high throughput is required.

2. By Application

Logic and Memory: Logic and memory devices are the backbone of semiconductor technologies, driving demand for etching equipment. Logic devices include processors and microcontrollers, while memory devices encompass DRAM (Dynamic Random Access Memory), flash memory, and other forms of storage. As the demand for higher-performing logic chips and memory storage solutions continues to rise, the need for advanced etching equipment to produce these devices increases.

MEMS (Micro-Electro-Mechanical Systems): MEMS devices are becoming increasingly prevalent in applications such as sensors, actuators, and communication systems. MEMS require precise etching processes to ensure the correct functionality of these small-scale mechanical and electrical systems. The growth of MEMS devices in automotive, healthcare, and telecommunications industries is expected to drive the demand for etch equipment.

Power Devices: Power semiconductor devices are used in power management systems, electric vehicles, renewable energy, and industrial applications. The increasing adoption of electric vehicles, renewable energy sources, and energy-efficient systems is boosting the demand for power semiconductors. These devices require specialized etching techniques to achieve the necessary performance and reliability, contributing to the growth of the etch equipment market.

Others: This category includes other specialized applications where etching is required, such as for optoelectronics, photonics, and advanced packaging. As new applications emerge, there is growing demand for specialized etching equipment capable of meeting the needs of these sectors.

Regional Insights

The semiconductor etch equipment market is geographically diverse, with different regions experiencing varying rates of growth based on local demand, industry development, and technological advancements.

1. North America

North America is one of the leading regions in the semiconductor etch equipment market, with a strong concentration of semiconductor fabs and research institutions. The United States, in particular, is home to some of the world's largest semiconductor companies and has been increasing its investments in semiconductor manufacturing to reduce reliance on foreign suppliers. As a result, the demand for advanced etch equipment is growing rapidly in this region. Moreover, the rise of emerging technologies such as 5G and AI is further driving the demand for semiconductors and the equipment used to produce them.

2. Europe

Europe is another significant player in the semiconductor etch equipment market. The region is home to leading semiconductor manufacturers, particularly in countries like Germany, France, and the Netherlands. The European Union's push for technological sovereignty and increased semiconductor production within the region is expected to drive market growth. Additionally, the growing focus on automotive semiconductors and MEMS devices in Europe is expected to boost the demand for etch equipment in the coming years.

3. Asia Pacific

Asia Pacific is the largest and fastest-growing region in the semiconductor etch equipment market, accounting for a substantial share of global demand. Countries like China, Japan, South Korea, and Taiwan are major players in semiconductor manufacturing, and the region continues to invest heavily in expanding its semiconductor production capabilities. The rapid adoption of emerging technologies, coupled with the increasing need for semiconductors in industries like consumer electronics, automotive, and telecommunications, is fueling the growth of the etch equipment market in Asia Pacific.

4. Latin America

Latin America is an emerging market for semiconductor etch equipment, with growing demand for semiconductors in industries such as automotive, telecommunications, and consumer electronics. While not as large as other regions, Latin America presents opportunities for market expansion, particularly as countries in the region increase their focus on technology and innovation.

5. Middle East & Africa

The Middle East and Africa represent a smaller market for semiconductor etch equipment but are expected to grow as the region invests in advanced technologies like 5G, AI, and smart cities. As the demand for high-performance semiconductors increases, the need for etch equipment will follow suit.

Key Market Players

The semiconductor etch equipment market is highly competitive, with several global players dominating the landscape. Some of the key players include:

Lam Research

TEL (Tokyo Electron)

Applied Materials

Hitachi High-Technologies

Oxford Instruments

SPTS Technologies

GigaLane

Plasma-Therm

SAMCO

AMEC

NAURA

These companies are at the forefront of innovation in semiconductor etch technology, continually developing new equipment to meet the growing demands of semiconductor manufacturers. They are also focused on expanding their global presence and partnerships to capture market share in key regions.

Conclusion

The semiconductor etch equipment market is set for significant growth over the next decade, driven by advancements in semiconductor manufacturing, increasing demand for high-performance chips, and the rise of emerging technologies. With a projected CAGR of 9.71% from 2024 to 2030, the market is expected to see robust demand across various segments, including logic and memory, MEMS, and power devices.

As semiconductor manufacturers continue to push the boundaries of miniaturization and performance, the role of advanced etch equipment will be crucial in achieving the precision and efficiency required for next-generation semiconductor devices. With innovation and investment in both equipment and technology, the semiconductor etch equipment market is poised for a bright future, with substantial opportunities for growth across regions.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.