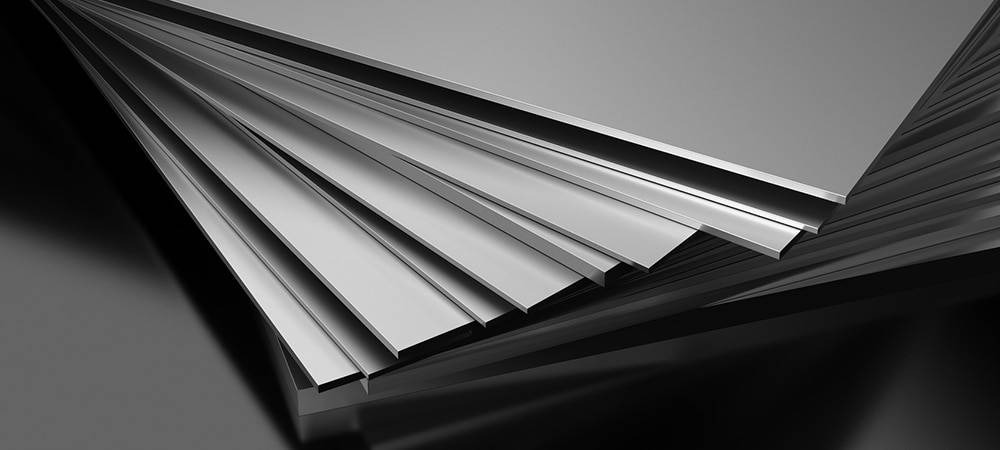

Stainless Steel 316Ti Sheets: The Ultimate Solution for Welded and High-Heat Components

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Stainless Steel 316Ti Sheets are a titanium-stabilized version of the widely used 316 grade. Designed to offer enhanced resistance to corrosion, especially at elevated temperatures, 316Ti sheets are ideal for demanding industrial environments such as chemical processing, marine equipment, and high-temperature applications. In this blog, we will explore the features, advantages, applications, and reasons why Stainless Steel 316Ti Sheets are a preferred material in critical industries.

What is Stainless Steel 316Ti?

Stainless Steel 316Ti is a titanium-stabilized austenitic stainless steel that is essentially 316 stainless steel with the addition of titanium. The titanium content, typically around 0.5%, enhances the material's resistance to sensitization, a form of intergranular corrosion that can occur after exposure to high temperatures (in the range of 500–800°C).

316Ti retains all the excellent mechanical and corrosion-resistant properties of 316, but with added stability when exposed to long-term heat. This makes it especially useful for welded structures or components operating in high-temperature environments.

Key Features of Stainless Steel 316Ti Sheets

1. Enhanced Corrosion Resistance

Like standard 316 stainless steel, 316Ti offers excellent resistance to chloride-induced pitting and crevice corrosion. This makes it highly suitable for use in marine and chemical environments.

2. Improved Heat Resistance

The addition of titanium improves the alloy’s resistance to sensitization during prolonged exposure to high temperatures. This makes 316Ti more reliable for applications like heat exchangers, boilers, and exhaust systems.

3. Superior Weldability

316Ti can be welded using standard techniques without the risk of carbide precipitation. This helps maintain corrosion resistance in the heat-affected zone (HAZ).

4. Excellent Mechanical Properties

It provides good strength, ductility, and toughness even in extreme conditions, allowing it to perform effectively in pressure vessels and structural applications.

5. Stabilized Structure

Titanium acts as a stabilizing element, binding with carbon and preventing chromium carbide formation. This ensures long-lasting resistance to corrosion, even after welding or heating.

Applications of Stainless Steel 316Ti Sheets

Due to its corrosion resistance, high-temperature stability, and strength, Stainless Steel 316Ti Sheets are used across a wide range of sectors, including:

• Chemical Processing Industry: Used in tanks, vessels, pipes, and valves handling corrosive chemicals.

• Pharmaceutical Equipment: Ideal for sterile environments due to its high cleanliness and corrosion resistance.

• Marine Industry: Used in ship components, offshore structures, and underwater piping systems.

• Heat Exchangers and Boilers: Resists scaling and stress cracking in high-temperature water and steam environments.

• Food and Beverage Industry: Applied in processing and handling equipment where hygiene and corrosion resistance are critical.

• Architectural Applications: Employed in façade panels and structures exposed to coastal or polluted atmospheres.

Comparison: 316 vs 316L vs 316Ti

• 316: Standard grade with good corrosion resistance, especially against chlorides.

• 316L: Low carbon version of 316, designed to reduce the risk of carbide precipitation during welding.

• 316Ti: Titanium-stabilized version that performs better at high temperatures and offers improved resistance to sensitization, particularly after welding.

While 316L is excellent for welded components at room to moderate temperatures, 316Ti is preferred for applications involving higher temperatures or prolonged exposure to corrosive conditions.

Benefits of Using Stainless Steel 316Ti Sheets

• Durability: Long-lasting performance, even in the harshest industrial environments.

• Low Maintenance: Resists rust, scaling, and fouling, minimizing cleaning and replacement costs.

• Hygiene: Non-reactive surface makes it ideal for cleanroom and sanitary environments.

• Thermal Stability: Maintains structural integrity at elevated temperatures.

• Versatility: Can be formed, welded, and machined easily for various custom applications.

Conclusion

Stainless Steel 316Ti Sheets are a highly reliable solution for industries that face aggressive environments, whether due to high heat, corrosive chemicals, or saltwater exposure. The titanium stabilization offers a unique advantage over standard 316 grades, particularly in maintaining corrosion resistance after welding or high-temperature exposure.

Whether you're in the chemical, marine, or food processing sector, choosing 316Ti sheets ensures performance, longevity, and peace of mind. With their proven track record in critical applications, Stainless Steel 316Ti Sheets are a smart investment for any project that demands strength, durability, and corrosion resistance.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.