Sugar Packing Machine: Ultimate Guide to Automated Sugar Packaging

Introduction to Sugar Packing Machines

In the modern food processing industry, sugar packing machines play a vital role in ensuring efficiency, hygiene, and consistency. These machines are designed to accurately weigh, fill, and seal sugar into various packaging formats, making them indispensable for sugar manufacturers and suppliers.

Types of Sugar Packing Machines

There are several types of sugar packaging machines, each catering to different needs in the industry:

1. Automatic Sugar Packing Machines

These machines operate with minimal human intervention, providing high-speed packaging solutions. Features include:

- High-precision weighing systems for accurate filling

- Automated sealing and cutting mechanisms

- Fast processing speeds, ideal for large-scale production

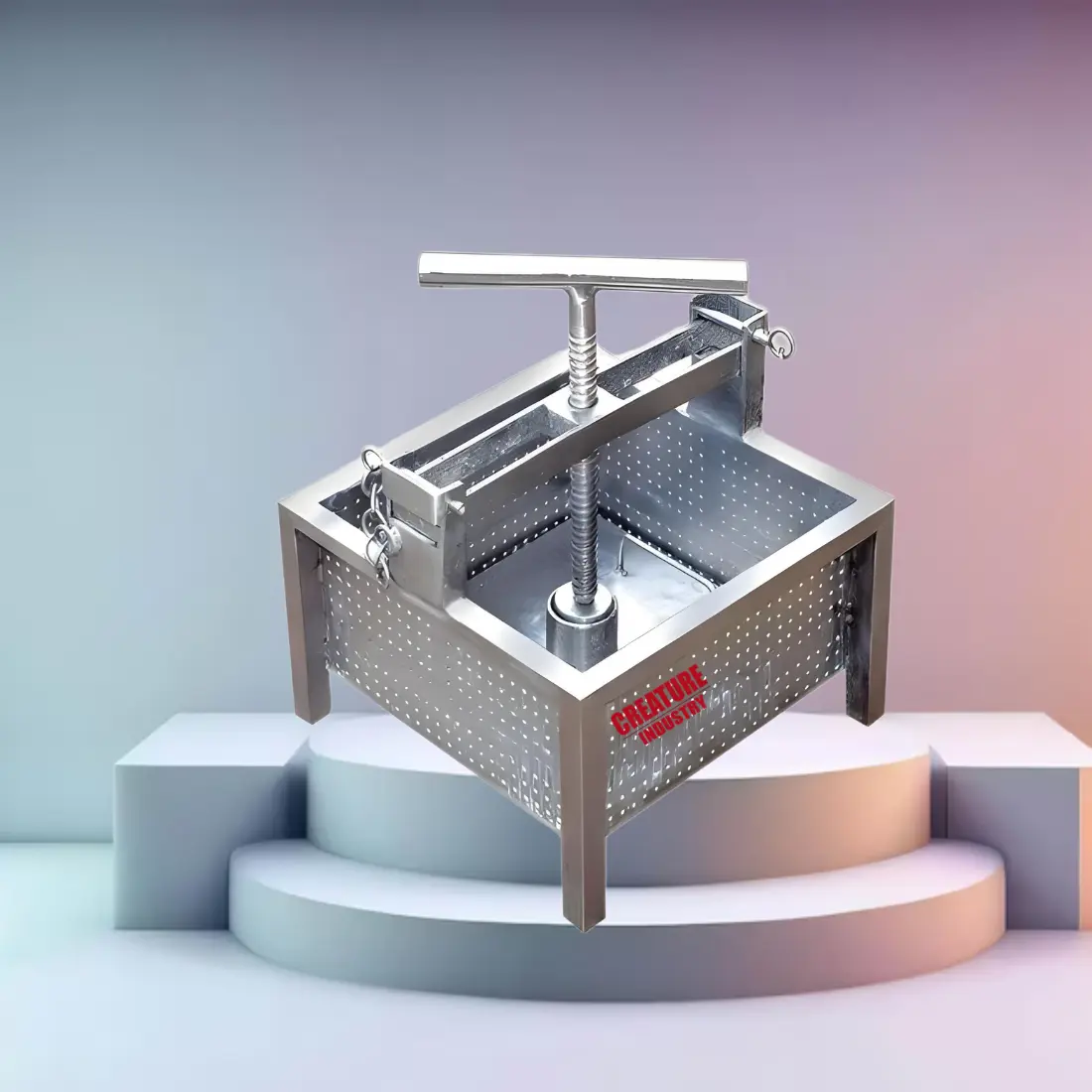

2. Semi-Automatic Sugar Packing Machines

These machines require some human intervention but still offer efficiency and accuracy. Best suited for medium-sized businesses.

3. Manual Sugar Packing Machines

Designed for small-scale businesses, these machines are cost-effective but require manual operation for filling and sealing.

Key Features of a High-Quality Sugar Packing Machine

When selecting a sugar packing machine, look for the following key features:

- Precision Weighing System – Ensures correct sugar quantities in each packet.

- Versatile Packaging Options – Ability to handle pouches, sachets, jars, or bulk packaging.

- Fast Packaging Speed – Determines the machine’s efficiency in high-demand production lines.

- Durable Stainless Steel Construction – Ensures longevity and hygiene compliance.

- Easy Maintenance and Cleaning – Reduces downtime and maintains hygiene standards.

- User-Friendly Control Panel – Simplifies operations with digital display and settings.

How Does a Sugar Packing Machine Work?

A fully automatic sugar packing machine follows a structured process:

- Sugar Feeding: The sugar is fed into the machine’s hopper.

- Weighing & Measuring: Advanced sensors measure the correct quantity.

- Filling: The sugar is directed into pre-formed pouches or sachets.

- Sealing: Heat-sealing technology ensures airtight packaging.

- Cutting & Dispensing: The packaged sugar is cut and sent for further processing.

- Batch Coding & Labeling: Date and batch information is printed.

Applications of Sugar Packing Machines

These machines are widely used in:

- Food Processing Industry – Packaged sugar for retail and bulk supply.

- Bakery & Confectionery – Ensuring precise sugar portions for recipes.

- Beverage Manufacturing – Quick sugar dispensing for coffee, tea, and soft drinks.

- Retail & Supermarkets – Pre-packaged sugar for direct consumer sales.

Benefits of Using a Sugar Packing Machine

- Increased Efficiency: Automation speeds up the packaging process.

- Consistency & Accuracy: Ensures uniform weight in every package.

- Reduced Labor Costs: Minimizes manual labor requirements.

- Enhanced Hygiene Standards: Prevents contamination and adheres to food safety regulations.

- Customizable Packaging: Adaptable to different packaging sizes and types.

Choosing the Best Sugar Packing Machine for Your Business

Before purchasing a sugar packaging machine, consider the following factors:

- Production Volume – High-speed machines for large-scale production, semi-automatic for moderate needs.

- Budget Constraints – Balance between affordability and features.

- Space Availability – Ensure your facility can accommodate the machine’s size.

- Maintenance & Spare Parts Availability – Choose brands with easily available parts.

- Compliance with Food Safety Standards – Machines should be FDA and ISO-certified.

Top Manufacturers of Sugar Packing Machines

Some renowned sugar packing machine manufacturers include:

- Creature Industry – High-quality automatic and semi-automatic machines.

- Bosch Packaging – Advanced solutions for the food industry.

- IMA Group – Reliable and efficient packaging systems

- MULTIVAC – Leading in hygienic and high-speed packing solutions.

Cost of Sugar Packing Machines

The price of a sugar packing machine varies based on automation level, brand, and capacity:

- Manual Machines – $1,500 - $5,000

- Semi-Automatic Machines – $5,000 - $15,000

- Fully Automatic Machines – $15,000 - $50,000+

Conclusion

Investing in a sugar packing machine enhances efficiency, accuracy, and hygiene in sugar packaging operations. Whether you're a small business or a large-scale producer, selecting the right machine can significantly impact productivity.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.