Sustainable Automation: How Green Technologies are Reshaping Manufacturing

Introduction

In recent years, the manufacturing sector has experienced a paradigm shift toward sustainability, driven by the need to reduce environmental impact and improve operational efficiency. Emerging technologies in industrial process automation are playing a crucial role in this transformation, leading to what is now referred to as sustainable automation. This article explores the latest developments in industrial automation, with a specific focus on how green technologies are reshaping the manufacturing landscape.

Understanding Sustainable Automation

Sustainable automation refers to the integration of innovative technologies that enhance manufacturing processes while minimizing ecological footprints. This approach not only addresses the pressing issue of climate change but also promotes resource efficiency, reduces waste, and encourages the use of renewable resources. As industries adopt sustainable practices, they are better positioned to meet regulatory requirements, improve their public image, and enhance profitability.

The Role of Emerging Technologies in Sustainable Automation

1. IoT and Smart Manufacturing

The Internet of Things (IoT) has revolutionized industrial automation by enabling real-time data collection and analysis. Smart sensors and connected devices provide manufacturers with insights into their processes, allowing them to optimize resource usage and reduce waste.

Key Benefits:

• Enhanced Monitoring: IoT devices can monitor energy consumption, emissions, and material usage, enabling manufacturers to identify inefficiencies.

• Predictive Maintenance: By analyzing data from machinery, companies can predict failures before they occur, reducing downtime and waste.

2. Artificial Intelligence (AI) and Machine Learning

AI and machine learning algorithms are being increasingly integrated into manufacturing processes to optimize production schedules, reduce material waste, and improve quality control.

Key Benefits:

• Data-Driven Decision Making: AI can analyze vast amounts of data to provide actionable insights that enhance operational efficiency.

• Quality Assurance: Machine learning algorithms can identify defects in real time, ensuring that only products meeting sustainability standards reach the market.

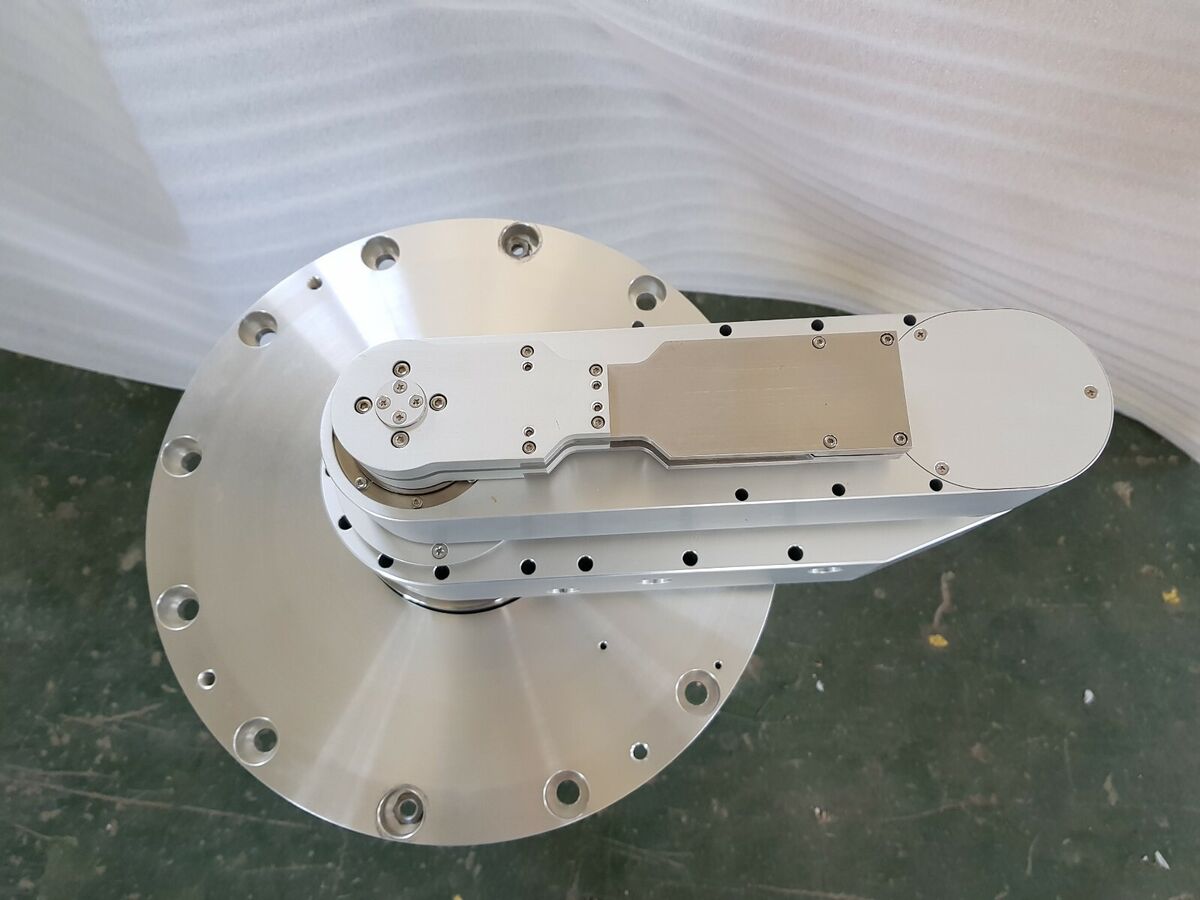

3. Robotics and Automation

Robotics is at the forefront of industrial automation, enabling manufacturers to streamline operations while reducing their carbon footprint. Collaborative robots, or cobots, work alongside human operators, enhancing productivity and safety.

Key Benefits:

• Reduced Energy Consumption: Modern robots are designed for energy efficiency, often utilizing less energy than traditional machines.

• Minimized Waste: Automation allows for precise material handling, significantly reducing waste during production.

4. Renewable Energy Integration

The integration of renewable energy sources into manufacturing processes is a crucial aspect of sustainable automation. Solar, wind, and biomass energy can power factories, reducing reliance on fossil fuels.

Key Benefits:

• Lower Operational Costs: Using renewable energy can significantly decrease energy bills in the long run.

• Carbon Footprint Reduction: Shifting to green energy sources is vital for manufacturers aiming to meet sustainability goals.

5. Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is transforming how products are designed and produced. This technology allows for the creation of complex geometries with minimal material waste.

Key Benefits:

• Material Efficiency: 3D printing uses only the necessary amount of material, reducing scrap and excess waste.

• Customization: This technology enables on-demand production, which can lower inventory costs and reduce overproduction.

Case Studies of Sustainable Automation in Action

1. Siemens and Energy Efficiency

Siemens has been a leader in promoting sustainable automation through its Digital Enterprise suite, which integrates IoT, AI, and automation technologies. By implementing energy-efficient solutions in its manufacturing facilities, Siemens has achieved significant reductions in energy consumption, demonstrating the potential for industries to minimize their carbon footprints.

2. Tesla’s Sustainable Production Practices

Tesla has revolutionized automotive manufacturing by implementing cutting-edge automation technologies that prioritize sustainability. The company utilizes renewable energy sources at its Gigafactories and employs advanced robotics to streamline production processes, significantly reducing waste and emissions.

3. Unilever’s Circular Economy Approach

Unilever has committed to achieving net-zero emissions by 2039. The company is investing in sustainable automation technologies to enhance efficiency across its supply chain, including IoT for better resource management and robotics for efficient production processes.

Challenges in Implementing Sustainable Automation

While the benefits of sustainable automation are clear, several challenges remain:

1. High Initial Investment

Implementing advanced technologies often requires significant upfront investment, which can be a barrier for smaller manufacturers.

2. Skill Gaps in Workforce

The transition to automated and sustainable practices demands a workforce skilled in new technologies. Training programs and educational initiatives are crucial to bridge this gap.

3. Resistance to Change

Cultural resistance within organizations can impede the adoption of new technologies. Leadership must foster an environment that embraces change and innovation.

Future Trends in Sustainable Automation

1. Circular Manufacturing

Circular manufacturing focuses on minimizing waste and maximizing resource efficiency. This trend will likely see increased adoption of recycling technologies and waste management systems within manufacturing processes.

2. Enhanced AI Capabilities

As AI continues to evolve, its application in predictive analytics and process optimization will deepen, further enhancing sustainability in manufacturing.

3. Increased Focus on Supply Chain Sustainability

Manufacturers are recognizing the importance of sustainable supply chains. Technologies that improve transparency and traceability will be critical for ensuring sustainable practices throughout the supply chain.

Conclusion

Sustainable automation is not just a trend; it is a fundamental shift in how manufacturing operates in the face of environmental challenges. By leveraging emerging technologies such as IoT, AI, robotics, and renewable energy, industries can optimize processes while significantly reducing their ecological impact. The future of manufacturing lies in embracing sustainable practices that prioritize efficiency, quality, and environmental responsibility. As the landscape of industrial automation continues to evolve, manufacturers that invest in sustainable technologies will not only thrive but also contribute to a healthier planet.

Read the complete blog: https://www.nextmsc.com/blogs/industrial-process-automation-market-trends

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.