Sustainable Water Treatment with Ceramic Membranes in India

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Water scarcity and pollution are two major challenges India faces, especially in the context of its growing population and industrial expansion. Traditional water treatment methods often struggle to keep up with these demands, leading to the need for more sustainable and efficient solutions. One such solution gaining popularity is ceramic membrane filtration.

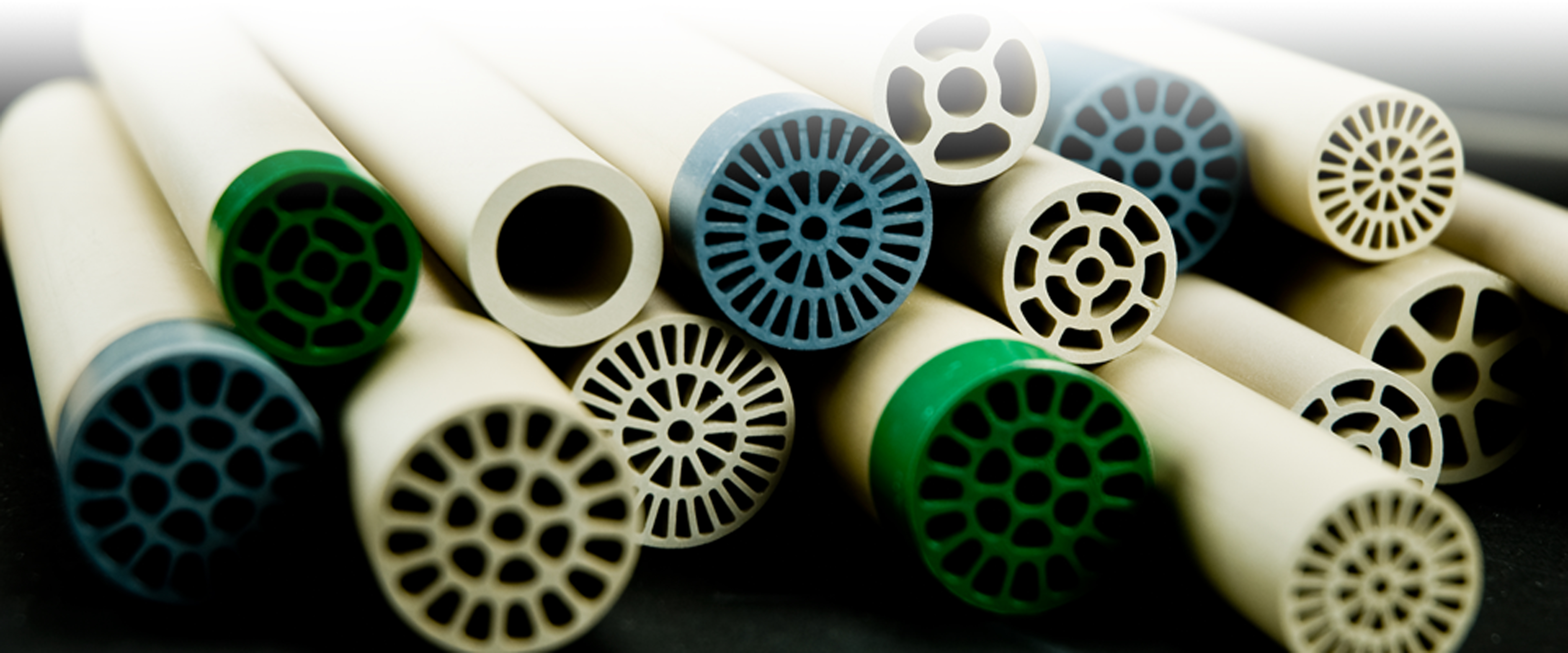

What are Ceramic Membranes?

Ceramic membranes are advanced filtration tools made from high-quality ceramics. These membranes are designed to filter out impurities from water, such as suspended solids, bacteria, and even viruses, using their porous structure. Unlike traditional polymer membranes, ceramic membranes are known for their durability, high-temperature resistance, and long lifespan, making them a sustainable choice for various water treatment applications.

Types of Water Treatment Ceramic Membranes Can Handle

Ceramic membranes can be used for different types of water treatment processes, each addressing specific water quality issues. The following are the most common types of water treatment that ceramic membranes are ideal for:

1. Reverse Osmosis (RO) Pre-Treatment: Ceramic membranes can serve as a pre-treatment to remove larger particles, thereby protecting reverse osmosis membranes from fouling. This process ensures the longevity of the RO system and improves water quality.

2. Microfiltration: In microfiltration, ceramic membranes are used to remove suspended solids, bacteria, and other contaminants from water. This is often used in industrial processes, wastewater treatment, and municipal water systems.

3. Ultrafiltration (UF): Ultrafiltration with ceramic membranes helps remove smaller particles, such as colloidal materials, proteins, and even some viruses. It’s especially beneficial for treating water in industries like food processing, pharmaceuticals, and textile manufacturing.

4. Greywater and Sewage Treatment: Ceramic membranes are highly effective in treating greywater (wastewater from sinks, showers, etc.) and sewage. By filtering out harmful contaminants, these membranes allow the treated water to be reused for non-potable purposes such as irrigation, flushing toilets, or industrial cleaning.

5. Oil-Water Separation: Ceramic membranes are also useful for separating oil from wastewater, which is common in industries like petrochemical and automotive sectors. The membranes efficiently remove emulsified oils, ensuring that the treated water meets discharge standards.

6. Desalination: In coastal regions where freshwater is scarce, ceramic membranes can help in desalination processes by removing salts and other impurities from seawater, making it suitable for drinking or industrial use.

Why Ceramic Membranes are Ideal for Water Treatment in India

India’s unique climatic and environmental conditions make ceramic membrane filtration an excellent choice for sustainable water treatment.

Here’s why:

• Durability: Ceramic membranes are highly durable and can withstand harsh environmental conditions such as high temperatures, extreme pH levels, and heavy fouling. This makes them ideal for India's varied climate, which can be challenging for other types of filtration systems.

• Low Maintenance: Unlike other water treatment methods, ceramic membranes require minimal maintenance. They have a longer lifespan, reducing the need for frequent replacements, making them a cost-effective solution for both urban and rural areas.

• Energy Efficiency: Ceramic membranes operate efficiently with lower energy consumption compared to other filtration systems, contributing to energy savings and reducing the overall environmental impact of water treatment.

• Eco-Friendly: These membranes are made from natural ceramic materials, which are more eco-friendly than synthetic alternatives. They help reduce chemical pollution and are easy to clean and reuse, making them a sustainable option for India’s water treatment needs.

Applications in India

Ceramic membrane technology has found a wide range of applications across various sectors in India, helping address water quality issues while promoting sustainability. Some of the key applications include:

• Industrial Water Treatment: Industries like textiles, food and beverage, pharmaceuticals, and automotive benefit from ceramic membrane filtration for water recycling, reducing water usage and improving operational efficiency.

• Agriculture: With water scarcity being a growing concern, ceramic membranes can help in the treatment of greywater for agricultural irrigation, thereby ensuring that crops are irrigated with safe water.

• Municipal Water Treatment: In urban areas, ceramic membranes help provide clean water for drinking, sanitation, and industrial use, while minimizing the environmental impact.

By leveraging IPNR Endura’s ceramic membrane technology for various waste water treatment needs, industries, municipalities, and agricultural sectors can contribute to the conservation of water resources, making it a crucial part of India’s sustainable water management strategy.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.