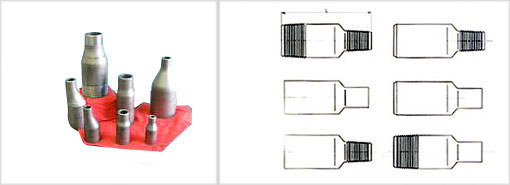

Swaged Nippolets Stlckists

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

We proudly offer a comprehensive variety of 86f68e4d402306ad3cd330d005134dac Swaged Nippolets (3000#) crafted from advanced-grade stainless steel. those fittings are especially engineered to provide premiere overall performance and sturdiness in an expansion of industrial packages. With their notable abrasion resistance, our Swaged Nippolets are designed to withstand the needs of excessive-stress environments, making sure reliability and durability.

Key functions

sturdiness: made from premium stainless-steel, our Swaged Nippolets are constructed to final. Their strong production allows them to resist put on and tear, making them suitable for long-term use in difficult conditions.

Abrasion Resistance: those fittings are designed to withstand damage from friction and effect, which is specially vital in industrial settings in which mechanical stress is a commonplace concern.

Versatility: to be had in numerous sizes and styles, our Swaged Nippolets can accommodate a huge variety of piping configurations, making them a great preference for diverse applications in different industries.

excessive-stress capability: Rated for 3000#, those Nippolets can take care of giant stress, making sure secure and green fluid transfer in various systems.

Corrosion Resistance: The stainless-steel fabric affords amazing resistance to corrosion, making our Nippolets appropriate to be used in environments in which exposure to moisture and chemical substances is a problem.

programs

Swaged Nippolets are extensively utilized in numerous sectors, such as:

Oil and fuel industry: In oil and gasoline extraction and processing, Swaged Nippolets are important for growing comfy connections in piping structures that transport crude oil, natural gas, and delicate merchandise. Their high-strain abilities cause them to especially precious on this subject.

Chemical Processing: The chemical industry regularly entails the transportation of competitive materials which could motive corrosion. Our Swaged Nippolets, with their corrosion-resistant residences, are well-suited for this utility, ensuring the integrity of the piping structures.

Water remedy: In water treatment facilities, efficient fluid transfer is important. Swaged Nippolets assist keep clean drift and cozy connections inside the piping networks that deal with water purification and distribution.

strength era: In electricity plants, in which steam and fluids are transported at high pressures, these fittings play a vital function in retaining gadget performance and safety.

creation: In building and infrastructure tasks, Swaged Nippolets are used to connect diverse piping structures, making sure dependable fluid transport for heating, cooling, and plumbing programs.

Technical specs

material Grades

Nickel Alloy:

ASTM / ASME SB 564:

america2200 (NICKEL two hundred)

america4400 (MONEL 400)

united states of america8825 (INCONEL 825)

usa6600 (INCONEL 600)

united states6601 (INCONEL 601)

usa6625 (INCONEL 625)

u.s.a.10276 (HASTELLOY C 276)

ASTM / ASME SB one hundred sixty:

united states2201 (NICKEL 201)

ASTM / ASME SB 472:

usa8020 (ALLOY 20 / 20 CB three)

Copper Alloy:

ASTM / ASME SB 61:

united statesC 92200

ASTM / ASME SB sixty two:

americaC 83600

ASTM / ASME SB 151:

u.s.70600, 71500 (CU-NI 90/10), C 71500 (CU-NI 70/30)

ASTM / ASME SB 152:

u.s.a.C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

chrome steel:

ASTM / ASME SA 182:

F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H

Duplex steel:

ASTM / ASME SA 182:

F 44, F 45, F fifty one, F 53, F 55, F 60, F sixty one

Carbon metal:

ASTM / ASME A 105

ASTM / ASME A 350 LF 2

Alloy steel:

ASTM / ASME A 182:

GR F five, F 9, F 11, F 12, F 22, F 91

nice assurance

At our facility, we adhere to strict exceptional manipulate measures to make sure that every Swaged Nippolet meets industry requirements. Our products go through rigorous checking out for dimensional accuracy, strength, and corrosion resistance. via sourcing only the greatest substances and using advanced manufacturing techniques, we assure the reliability and overall performance of our fittings.

end

Our Swaged Nippolets (3000#) represent the pinnacle of engineering excellence, combining durability, versatility, and high-stress capability in one dependable product. whether or not you are in the oil and fuel sector, chemical processing, water remedy, power technology, or creation, our fittings are designed to fulfill your particular desires and exceed your expectations.

if you have any questions or require additional facts approximately our Swaged Nippolets, please don’t hesitate to contact us. we're devoted to presenting you with the very best high-quality merchandise and extremely good customer support.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.