Synthetic Rubber Market Size Analysis: Key Trends in Automotive and Industrial Applications

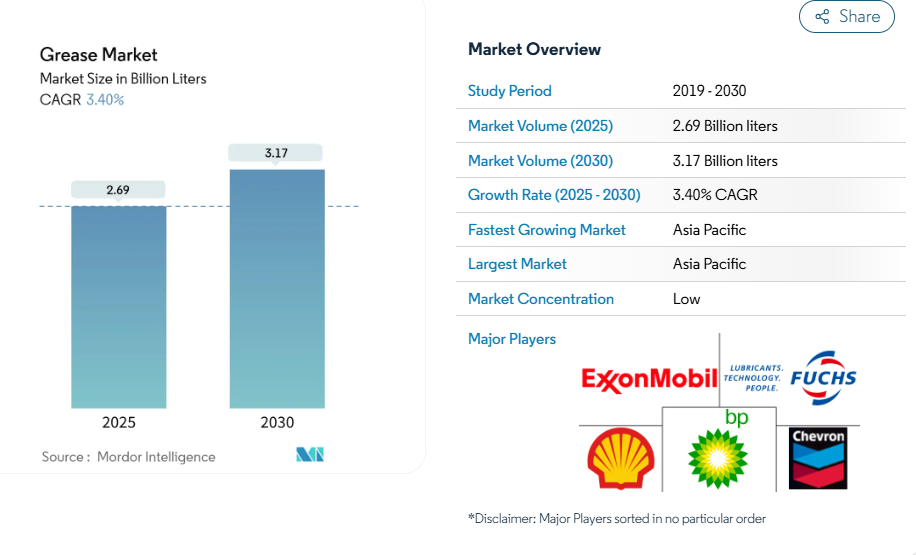

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

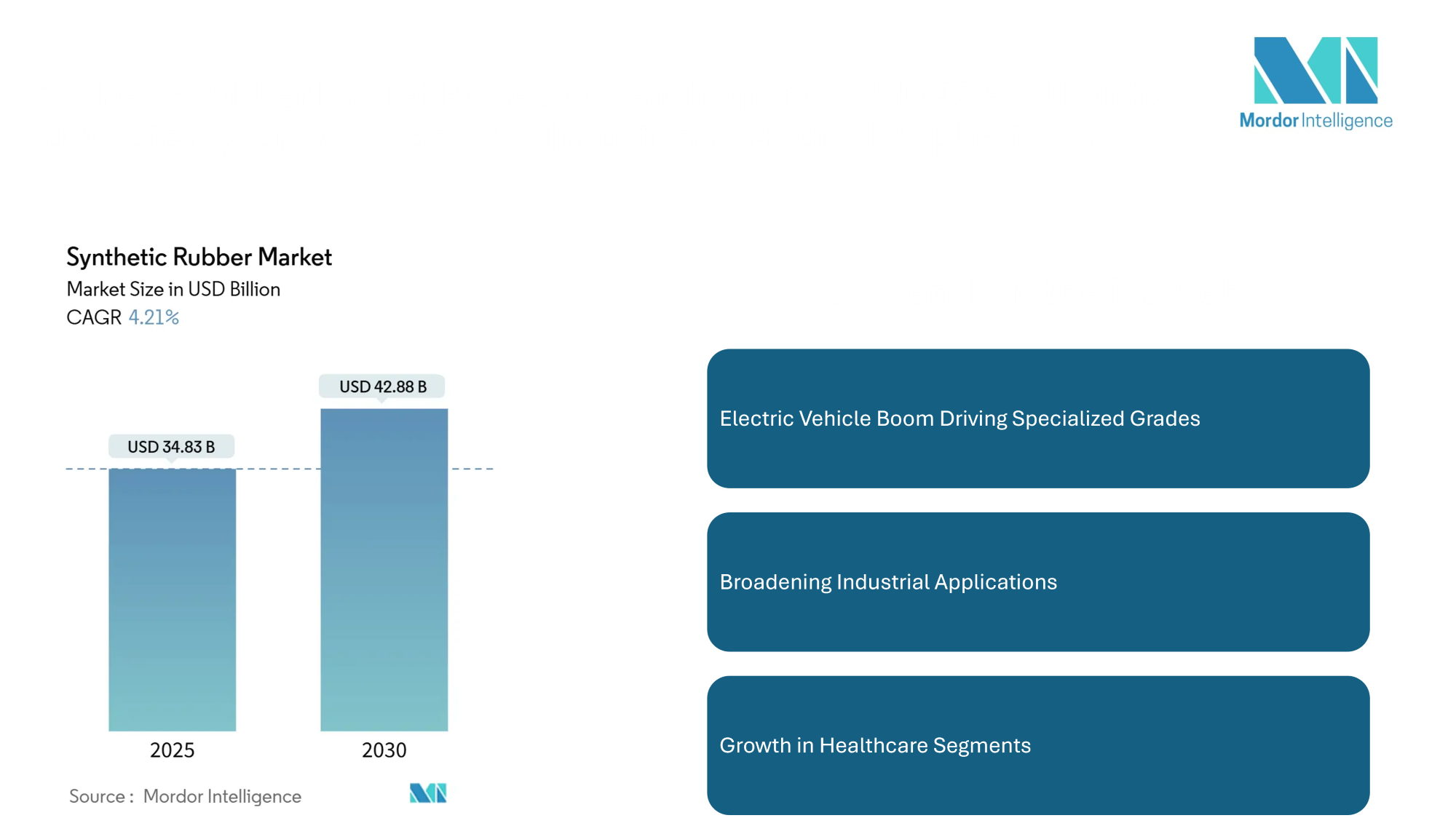

Mordor Intelligence has published a new report on the “Synthetic Rubber Market”, offering a comprehensive analysis of trends, growth drivers, and future projections.

Introduction: Steady Growth in a Versatile Industrial Material

The global synthetic rubber market is witnessing consistent expansion, driven by its critical role across multiple industries, including automotive, footwear, construction, and electronics.

According to Mordor Intelligence, the synthetic rubber market is estimated at USD 34.83 billion in 2019 and is projected to grow to USD 42.88 billion by 2030, registering a Compound Annual Growth Rate (CAGR) of 4.21% during the forecast period.

Synthetic rubber, derived from petroleum-based monomers, has become an indispensable alternative to natural rubber due to its superior elasticity, resistance to wear, and ability to perform under extreme conditions. With evolving demand patterns, especially in automotive tires, industrial goods, and consumer products, the market is positioned for steady development globally.

Get expert-backed research and strategic insights—view the complete analysis here: https://www.mordorintelligence.com/industry-reports/synthetic-rubber-market?utm_source=indiblog

Key Trends Driving Market Momentum

Automotive Sector Demand Remains Dominant

One of the primary growth drivers of the synthetic rubber industry is the strong demand from the automotive sector. Synthetic rubber is extensively used in the production of tires, belts, hoses, and seals. The tire industry alone accounts for a significant portion of the global synthetic rubber consumption. The increasing production of electric and hybrid vehicles worldwide is also contributing to rising demand, particularly for performance tires and durable components.

Rising Infrastructure and Industrial Activity

Ongoing infrastructure development in emerging economies is boosting the need for synthetic rubber in construction applications. This includes its use in adhesives, sealants, and waterproofing materials. Additionally, synthetic rubber is integral in manufacturing various industrial products such as conveyor belts, gaskets, and molded components.

Preference for Synthetic Over Natural Rubber

Synthetic rubber offers several advantages over natural rubber, including better resistance to oil, heat, abrasion, and aging. These properties make it particularly valuable in high-performance and industrial applications. With global natural rubber supply being subject to climatic variations and geopolitical factors, industries are increasingly leaning toward synthetic alternatives for consistency and reliability.

Focus on Sustainable and Bio-Based Alternatives

While the market is primarily petroleum-based, there is a growing interest in developing bio-based synthetic rubbers to reduce environmental impact. Research into renewable feedstocks and recyclable rubber materials is gaining momentum, reflecting the industry’s gradual shift toward more sustainable practices.

Check out more details and stay updated with the latest industry trends, including the Japanese version for localized insights: https://www.mordorintelligence.com/ja/industry-reports/synthetic-rubber-market?utm_source=indiblog

Market Segmentation: Diverse Applications and Regional Presence

The synthetic rubber market is segmented based on product type, application, and geography.

By Product Type:

Styrene-Butadiene Rubber (SBR): The most commonly used synthetic rubber, especially in tire manufacturing due to its abrasion resistance and aging stability.

Polybutadiene Rubber (PBR): Known for high resistance to wear and low-temperature performance, widely used in tires and industrial goods.

Ethylene Propylene Diene Monomer (EPDM): Used in roofing membranes, automotive weather seals, and hoses.

Nitrile Butadiene Rubber (NBR): Favored in applications requiring oil and fuel resistance, such as gaskets and seals.

Others: Includes chloroprene rubber, isoprene rubber, and specialty rubbers used in niche sectors.

By Application:

Tires and Automotive Components: The dominant segment due to the scale of tire production globally.

Footwear: Synthetic rubber is used in soles and other shoe components.

Industrial Goods: Includes belts, seals, hoses, and vibration dampers.

Construction: Used in waterproofing, adhesives, and sealants.

Electrical and Electronics: Employed for insulation and flexible components.

Others: Includes healthcare, consumer goods, and aerospace applications.

By Geography:

Asia-Pacific: Holds the largest share of the global market, led by countries like China, India, and Japan. The region is a manufacturing hub for automotive, footwear, and electronics industries, all of which drive rubber demand.

Europe: A significant market due to the presence of automotive manufacturing giants and a growing emphasis on high-performance synthetic rubbers.

North America: Benefits from advanced industrial activity and technological research in rubber formulations.

South America, Middle East & Africa: Growing industrial infrastructure and automotive assembly plants are contributing to gradual growth in these regions.

Explore the full report for in-depth insights and market forecasts: https://www.mordorintelligence.com/industry-reports/synthetic-rubber-market?utm_source=indiblog

Key Players Shaping the Competitive Landscape

The synthetic rubber market is moderately consolidated with several global and regional manufacturers. Key players are focusing on enhancing production capabilities, investing in R&D, and forming strategic partnerships to meet the growing demand and environmental regulations.

China Petrochemical Corporation (Sinopec): A major player in Asia-Pacific, offering a broad portfolio of synthetic rubbers for tires and industrial use.

TSRC Corporation: Known for specialty rubber production, serving diverse industries including automotive and footwear.

LG Chem Ltd.: Focuses on high-performance rubber grades with applications in electronics and automotive.

Zeon Corporation: Engaged in manufacturing synthetic rubbers and specialty elastomers, catering to high-end applications.

LANXESS AG: A German chemical company offering innovative synthetic rubber products with emphasis on sustainability.

Versalis S.p.A. (Eni S.p.A.): Active in the European market with a range of rubber types used in automotive and technical sectors.

Kumho Petrochemical Co. Ltd.: Supplies a wide variety of synthetic rubbers globally, with a strong presence in tire manufacturing.

These companies are adopting strategies like capacity expansion, mergers, and eco-friendly product innovation to stay competitive in a rapidly evolving market.

Conclusion: Outlook for a Versatile Industrial Staple

The synthetic rubber market is on a path of stable growth, backed by strong demand from the automotive, industrial, and construction sectors. Its versatility and superior performance characteristics continue to position it as a vital material across multiple applications. The shift toward cleaner mobility, rising industrial production in emerging markets, and the push for sustainable rubber alternatives are expected to shape the future trajectory of this market.

Global industries adapt to changing environmental and performance demands, synthetic rubber will remain a key component in bridging reliability with functionality in modern manufacturing. With ongoing research and capacity investments, the market is poised for continued relevance and resilience.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.