TFT LCD Manufacturing Plant Project Report 2025: Manufacturing Plant Setup and Operations

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

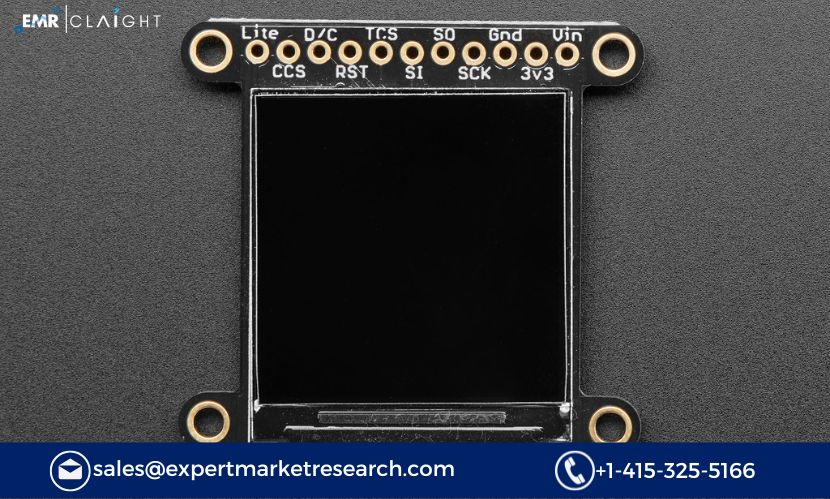

Thin-Film Transistor Liquid Crystal Display (TFT LCD) technology has revolutionized the display industry, offering high-quality visuals for a variety of applications, including smartphones, televisions, computers, and other electronic devices. The increasing demand for high-definition displays across various sectors, including consumer electronics, automotive, and industrial applications, has led to the rapid growth of the TFT LCD market. This TFT LCD Manufacturing Plant Project Report provides an in-depth analysis of the industry, outlining the key components involved in setting up a TFT LCD manufacturing plant, the production process, market opportunities, and financial considerations.

Market Demand

1. Growing Demand for Consumer Electronics

The global demand for consumer electronics, particularly smartphones, tablets, and televisions, has significantly contributed to the rapid growth of the TFT LCD market. As consumer electronics evolve, the need for advanced display technologies such as TFT LCD has escalated. The increasing penetration of smartphones and the development of ultra-high-definition television sets have further driven the demand for TFT LCD panels. The growing trend of larger, thinner, and more energy-efficient screens continues to push the market forward.

2. Increasing Use in Automotive Industry

The automotive sector has also embraced TFT LCD technology, particularly for the development of digital dashboards, infotainment systems, and advanced driver-assistance systems (ADAS). The demand for high-resolution, touch-enabled displays in vehicles is on the rise, making TFT LCD technology essential for the automotive industry. As smart vehicles and electric vehicles gain popularity, the automotive industry's demand for TFT LCD displays is expected to increase.

3. Rise of Commercial and Industrial Applications

Beyond consumer electronics, TFT LCDs are also used in various commercial and industrial applications. From point-of-sale (POS) systems, medical devices, and digital signage to industrial control panels, TFT LCDs provide clear, high-quality visual output in a variety of settings. The increasing adoption of digital signage and the proliferation of interactive kiosks in retail and hospitality sectors contribute to the growing demand for TFT LCDs.

4. Demand for High-Resolution Displays

With the rise of gaming, virtual reality (VR), and augmented reality (AR) applications, the demand for higher-resolution displays has surged. The need for displays with improved color accuracy, contrast, and refresh rates has made TFT LCD technology an ideal solution. As high-definition, ultra-high-definition (4K, 8K), and OLED displays gain momentum, the TFT LCD market has also evolved to meet these needs, creating opportunities for high-quality panel manufacturing.

5. Emerging Markets

As developing economies continue to grow, there is an increasing demand for consumer electronics and digital displays. TFT LCD technology has seen widespread adoption in emerging markets, where access to smartphones, televisions, and other electronics is expanding rapidly. Countries in Asia-Pacific, Latin America, and the Middle East are expected to drive the growth of the TFT LCD market due to their expanding middle class and improved living standards.

Plant Location and Infrastructure

1. Proximity to Raw Material Suppliers

The manufacturing of TFT LCD panels requires a variety of specialized raw materials, including glass substrates, indium tin oxide (ITO), liquid crystal materials, and various chemicals for film deposition and patterning. Ideally, the plant should be located near raw material suppliers to reduce logistics costs and ensure a steady supply of materials. Proximity to high-tech suppliers and equipment manufacturers is also beneficial for efficient plant operations.

2. Access to Skilled Labor

Setting up a TFT LCD manufacturing plant requires highly skilled labor in areas such as materials science, electrical engineering, and process automation. The plant should be located in regions with access to a skilled workforce that can handle advanced production technologies and maintain strict quality standards. Collaborations with local universities and technical institutions can also help in workforce training and development.

3. Regulatory Compliance and Certification

The plant location should adhere to local regulations concerning environmental sustainability, waste management, and health and safety standards. It must meet international quality standards such as ISO certifications for manufacturing and safety protocols. Given the critical nature of electronic displays in consumer products, obtaining certification from organizations like Underwriters Laboratories (UL) and International Electrotechnical Commission (IEC) may also be necessary for compliance.

4. Infrastructure Needs

The TFT LCD manufacturing plant requires significant infrastructure for smooth operations. The plant must have adequate space for production lines, quality control laboratories, storage for raw materials, and finished products. Clean rooms, temperature and humidity control systems, and controlled environments are essential to prevent contamination during the delicate manufacturing process. Additionally, sufficient power supply, water supply, and waste treatment facilities are required for uninterrupted operations.

5. Transportation and Logistics

Efficient logistics are crucial for managing the transportation of raw materials to the plant and the delivery of finished products to customers. The plant should be strategically located near major transportation hubs, such as ports, airports, and highways, to facilitate the timely movement of goods. Proximity to international markets can reduce shipping costs and improve the competitiveness of the product in the global market.

Manufacturing Process

The manufacturing process of TFT LCD panels involves a series of complex steps that require precise control of materials and technology. Below is an overview of the key steps involved in the production of TFT LCDs:

1. Glass Substrate Preparation

The TFT LCD production process begins with the preparation of the glass substrate. The glass is first cleaned to remove any dust, dirt, or contaminants. It is then cut into the desired size, based on the final product specifications. The substrate acts as the base on which the rest of the TFT LCD layers will be built.

2. Deposition of Thin Films

The next step involves the deposition of various thin films onto the glass substrate. These films include the transparent conductive oxide layer (ITO), the gate metal layer, and the active matrix TFT layer. These thin films are deposited using methods such as sputtering or chemical vapor deposition (CVD). The precise control of film thickness is essential for the performance of the final display.

3. TFT Array Formation

The TFT array consists of thin-film transistors, which control the pixels of the display. Photolithography is used to pattern the transistors and the associated wiring on the glass substrate. This step requires highly precise equipment, as the TFTs must be correctly aligned to enable the display to function effectively.

4. Liquid Crystal Injection

Once the TFT array is formed, the liquid crystal layer is injected between two glass substrates. The liquid crystals are carefully controlled to ensure that they align correctly and provide the desired visual output. The space between the glass substrates is sealed, and the liquid crystals are encapsulated, forming the core of the TFT LCD panel.

5. Color Filter and Polarizer Layer

Next, the color filter layer is applied to the panel. The color filter is responsible for creating the red, green, and blue pixels that form the color image on the display. A polarizer layer is also added to control the passage of light through the liquid crystal layer, helping to improve image quality and contrast.

6. Assembly and Packaging

After the color filter and polarizer layers are applied, the display panel is assembled and connected to the necessary driving circuitry. The display panel is then tested to ensure it meets the required performance standards. Once testing is complete, the TFT LCD is packaged into its final form, whether for use in televisions, monitors, smartphones, or other electronic devices.

7. Quality Control

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that the final product meets industry standards. Testing includes checks for uniformity of color, brightness, resolution, and contrast. The panels are also subjected to durability tests, such as stress tests, to ensure their longevity and reliability.

Equipment Required

To set up a TFT LCD manufacturing plant, a range of advanced equipment is necessary. Some of the key machinery includes:

Glass Cutting and Cleaning Machines: For preparing the glass substrates.

Sputtering and CVD Equipment: For the deposition of thin films.

Photolithography Machines: For patterning the TFT array.

Liquid Crystal Injection Systems: For the injection of liquid crystals into the panel.

Color Filter and Polarizer Coating Equipment: For applying the color filter and polarizer layers.

Assembly and Testing Equipment: For final assembly, quality control, and packaging.

Environmental Control Systems: To maintain clean room conditions, temperature, and humidity.

Financial Planning and Investment

1. Initial Investment

The capital investment required to establish a TFT LCD manufacturing plant is substantial. The cost includes land acquisition, factory construction, machinery procurement, and raw material purchase. In addition, investments in research and development (R&D) may be necessary to improve the quality and efficiency of production. The plant will also need to comply with stringent environmental regulations, which may require additional capital outlay for waste management systems.

2. Operating Costs

Operating costs for a TFT LCD manufacturing plant include raw material procurement, energy consumption, labor costs, maintenance of machinery, and packaging materials. The cost of raw materials, especially the specialized chemicals and glass used in the production of TFT LCD panels, can be significant. Efficient energy management and waste reduction strategies will help minimize operating expenses.

3. Revenue Generation

The primary source of revenue for the plant will come from the sale of TFT LCD panels to original equipment manufacturers (OEMs), consumer electronics brands, automotive companies, and industrial sectors. By producing high-quality, advanced TFT LCD panels, the plant can target premium markets and establish strong partnerships with leading electronic device manufacturers.

4. Profitability

Profitability in the TFT LCD manufacturing industry depends on factors such as production efficiency, cost management, and the ability to meet market demands for advanced display technologies. The growing demand for larger and more energy-efficient displays, coupled with advancements in panel technology, presents significant opportunities for profitability. Additionally, continuous innovation and the ability to scale production will contribute to long-term financial success.

Media Contact

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.