The Complete Buyer’s Guide to Three-Phase Transformers from KTC GmbH

In today's energy age, power reliability and distribution efficiency have constructed onto essential issues. Be it for a manufacturing plant, infrastructure project, or power system scaling, a choice concerning the three phase transformer directly affects systems' performance, safety, and ultimate cost-effectiveness.

Then where to start? With so many types and technical details coming into play? This guide shall help you with everything you need to know before purchasing a three-phase transformer — with great insights from the industry and a look at trustworthy German manufacturer KTC GmbH.

What Is a Three-Phase Transformer and Why Does It Matter?

A three-phase transformer is an electrical device meant to convert voltage levels in systems operating on three-phase power. In contrast, a single-phase transformer is suitable for small-scale or residential loading. Large-scale, high-power facilities such as industrial equipment, utility grids, and renewable energy projects call for three-phase transformers. The transformers provide:

Efficient energy distribution

Balanced electrical load

Reduced transmission losses

With ever-increasing power demand and growing efficiency standards, high-quality three-phase transformer investment is becoming a strategic necessity.

Why Choose a Three-Phase Transformer?

Here are the reasons for which industry and infrastructural applications prefer three-phase transformers:

More Efficiency

The three-phase transformers, in comparison to the single-phase type, transmit more power for lesser conductor material spent, thereby promoting energy conservation.

Load Balancing

Three-phase power ensures smooth and well-balanced flow, minimizing stress on equipment and voltage drops.

Scalability

They may assist in scaling up, be it a growing factory or a power-hungry data centre.

Enhanced Voltage Regulation

As critical voltage fluctuations are better controlled, equipment or operations may become sensitive.

Heavy and commercial industrial use

They are expected to operate under heavy loads continuously, from assembly lines to commercial HVAC systems.

Key Factors to Consider Before You Buy

Selecting the ideal transformer is not just a matter of power rating. There are several parameters and features you should assess:

Power & Voltage Ratings

Primary and secondary voltage ratings should be suited to your system requirements. This establishes the incompatibility and performance.

Core Design: Laminated Vs. Toroidal

Laminated Core: The standard and cost-effective option; used in most industrial applications.

Toroidal Core: Otherwise compact and silent; used where space or noise is a concern.

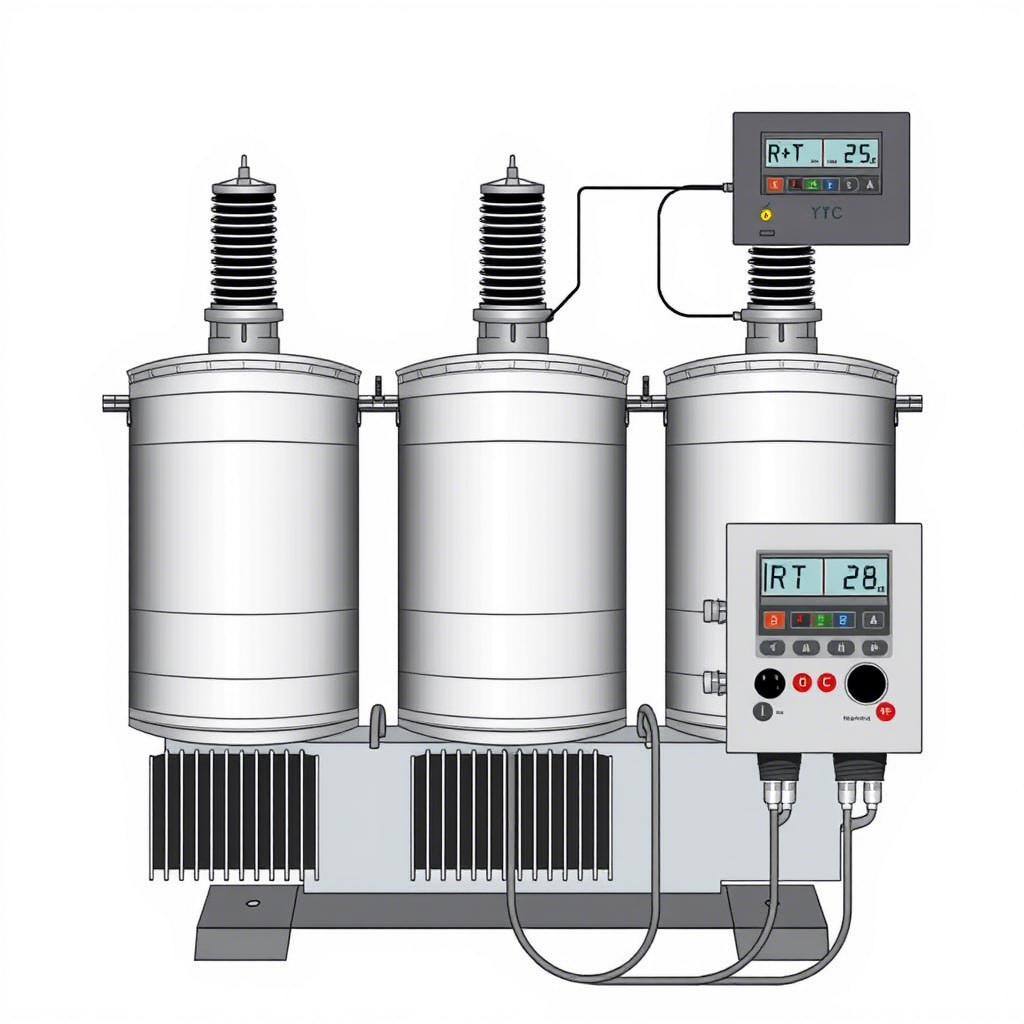

Cooling System: Dry Type Vs. Oil Immersed

Dry-Type Transformers: They are best suited for indoor use; less maintenance.

Oil-Immersed Transformers: Great for outdoors or high-load environments; the best thermal performance available.

Insulation and Enclosure

Depending on whether the unit will be indoors, outdoors, or placed in harsh environments, look for its insulation class and IP rating.

Certifications and Compliances

Implement standards of international safety and quality:

IEC

ISO

CE

The above standards, like efficiency, safety, and legal compliance, ensure reliability. Load Type & Duty Cycle

Know if your application needs continuous load handling or occasional peak

Common Applications of Three-Phase Transformers

Across practically every industry that needs stable high-voltage power-rapid delivery are considered to be three-phase transformers. Some important instances include:

Industrial: Conveyor belts, heavy machinery, motor drives

Commercial Buildings: HVAC, elevator, lighting systems

Renewables: Solar farm, wind turbine, battery storage Systems

Infrastructure: Data centers, Telecom networks, airports

Utilities: Power substations, grid distribution

Latest Trends & Innovations in Transformer Technology

There is a transformation going in the transformer industry, with modern designs going into being smarter, safer, and more efficient. Some of the key trends include:

Smart Transformers

IoT sensors provide for real-time monitoring, predictive maintenance, and remote diagnostics.

Eco-Friendly Materials

Low-loss cores and energy-efficient insulation materials reduce environmental impact and operating costs.

Modular & Assembled Designs

Space-saving designs for urban infrastructures and prefab installation.

Global Energy Standards

Meet new efficiency performance criteria such as EU EcoDesign directives and US DOE standards.

Why Choose KTC GmbH for Your Three-Phase Transformer Needs?

Located in Germany and known for precision engineering, KTC GmbH is one of the leading manufacturers of custom and standard three-phase transformers for high-performance applications.

Engineering Excellence

Every transformer is manufactured with premium materials and tested as per international standards.

Tailored Solutions

KTC supplies both off-the-shelf and custom-built transformers based on your requirements for voltage, load, and environmental conditions.

Certifications & Compliance

Fully certified according to IEC standards, ISO standards, and CE marking, proving reliability and acceptance worldwide.

Technical Support

Having an expert workforce providing direct support through the entire customer journey-from consulting to post-installation.

Explore Your Options with KTC GmbH

KTC GmbH will assist with providing consultation and technical support for any newcomers that are new to the field when it comes to selecting the perfect transformer for a new installation or system upgrade.

Conclusion: Make an Informed, Future-Ready Choice

Buying a three-phase transformer is definitely a long-term investment. It affects safety, reliability, and operational efficiency.

Upon knowing technical considerations and astuteness in industry developments can guide an investor in selecting the right product for his application. And at KTC GmbH, there is complete assurance of German quality standards, international compliance, and expert support.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

![Passenger Car Green Tire Market Trends: 2029 Outlook and Market Analysis [Growth Rate: 4.59%]](https://indibloghub.com/public/images/courses/67343c179c5295432_1731476503.png)