The Efficiency of Rotary Lobe Pumps in Handling High Viscosity Fluids

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

When it comes to pumping high viscosity fluids, there’s a wide variety of equipment to choose from. However, not all pumps are designed to handle these thick, heavy liquids with efficiency and reliability. Among the most reliable and effective options is the rotary lobe pump. These pumps are designed specifically for handling fluids with high viscosity, making them invaluable in industries such as food processing, pharmaceuticals, chemicals, and more. This article will delve into how rotary lobe pumps work, their advantages, and how they efficiently handle high viscosity fluids, providing insight into why they’re the go-to solution for many industries.

What is a Rotary Lobe Pump?

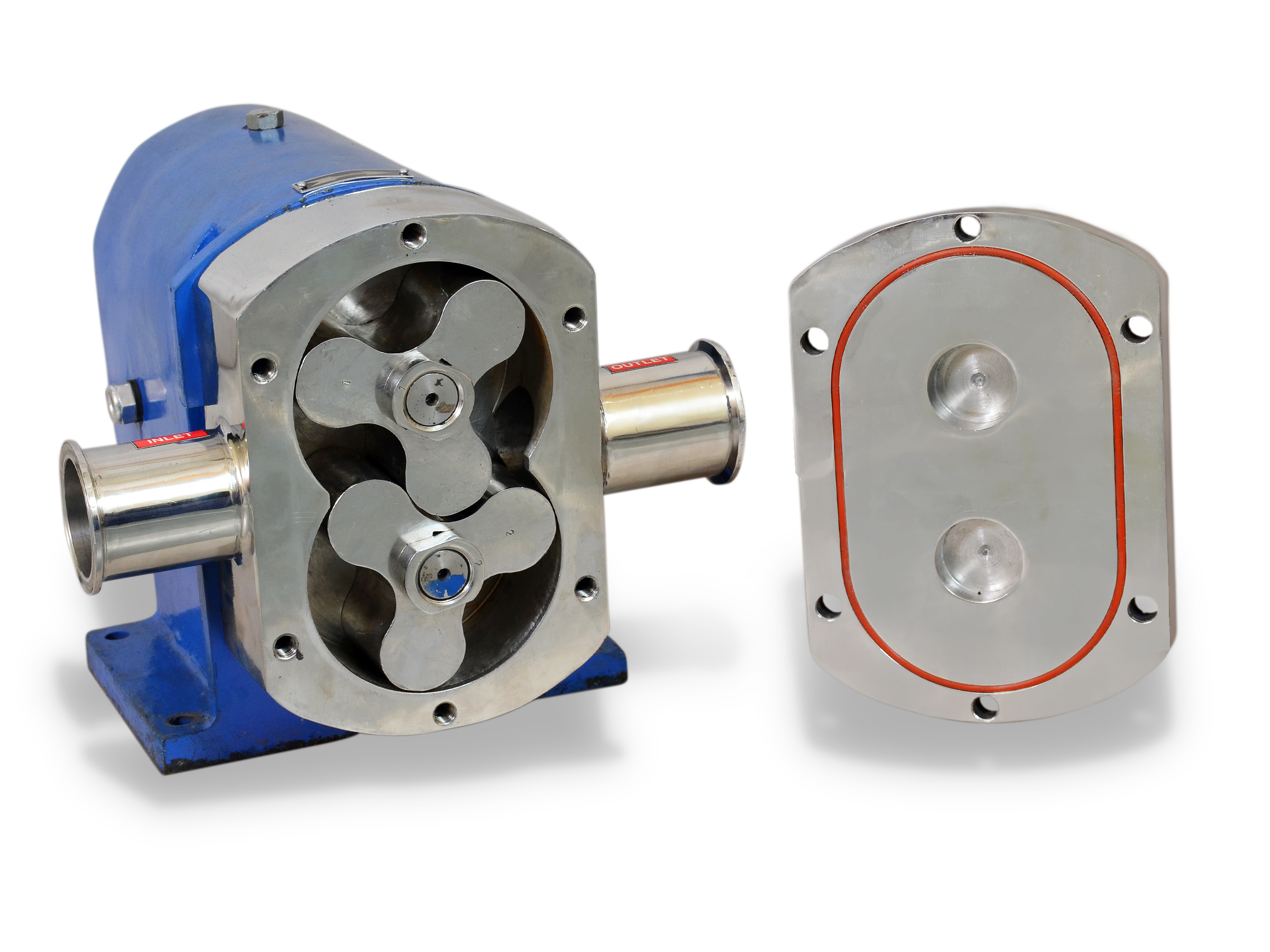

A rotary lobe pump is a type of positive displacement pump that uses two or more lobes rotating in opposite directions to move fluids. These pumps are especially known for their ability to handle high viscosity fluids, such as syrups, oils, pastes, and sludges, without causing damage or losing efficiency. The design and operation of these pumps make them perfect for transferring both thick and shear-sensitive fluids.

Unlike centrifugal pumps, which rely on high-speed rotation to move fluids, rotary lobe pumps offer a gentler and more controlled flow, making them ideal for delicate fluids that can’t tolerate turbulence or high shear forces.

How Do Rotary Lobe Pumps Work?

The operation of a rotary Lobe Pump is simple yet effective. The pump consists of two rotating lobes that mesh together and rotate within a casing. As the lobes turn, they create cavities on the inlet side that fill with fluid. The fluid is then carried around the casing and discharged on the outlet side. This action creates a smooth, continuous flow of fluid without the pulsations typically seen in other types of pumps.

Key Components of a Rotary Lobe Pump:

Lobes: These are the primary components responsible for fluid movement. They come in different shapes (e.g., gear-like, oval) depending on the specific design of the pump.

Casing: The casing contains the rotating lobes and is designed to create a vacuum-like effect on the inlet side.

Shaft: The shaft connects the lobes to the motor, allowing them to rotate in opposite directions.

Seals: Seals ensure that there is no leakage during the pumping process, especially when handling thick fluids.

Advantages of Rotary Lobe Pumps for High Viscosity Fluids

1. Efficient Handling of High Viscosity Fluids

One of the biggest advantages of rotary lobe pumps is their ability to handle high viscosity fluids efficiently. The positive displacement nature of the pump ensures that even thick, viscous liquids can be pumped without significant loss of flow rate. The cavities formed by the lobes help to transport the thick fluid without causing excessive pressure buildup, which is common in centrifugal pumps.

2. Low Shear Forces

Many high viscosity fluids are shear-sensitive, meaning that exposure to high shear forces can damage the fluid’s composition. Rotary lobe pumps generate low shear forces, which makes them ideal for pumping shear-sensitive fluids such as food, pharmaceuticals, and certain chemicals. By gently moving the fluid without disturbing its structure, Ace Lobe Pumps ensure that the quality of the fluid is preserved during the pumping process.

3. Gentle, Pulsation-Free Flow

Rotary lobe pumps provide a pulsation-free flow, which is crucial when dealing with high viscosity fluids. Pulsation can cause uneven flow, resulting in pressure fluctuations and inefficient pumping. The smooth flow provided by rotary lobe pumps ensures that the fluid is moved efficiently without any disruptions, providing consistent performance over time.

4. Wide Range of Applications

From food production to chemical manufacturing, rotary lobe pumps are versatile and used across various industries. Whether you need to pump syrups, pastes, or thick oils, Ace Lobe Pumps can be customized to meet specific fluid handling requirements. Their ability to handle a wide range of fluids with varying viscosities makes them indispensable in many manufacturing processes.

The Role of Rotary Lobe Pumps in the Food Industry

The food industry is one of the major sectors that benefit from the efficiency of rotary lobe pumps. In this industry, many products, such as jams, sauces, and dairy products, have high viscosities and require careful handling during production. Ace Lobe Pumps excel in this area due to their ability to handle delicate, thick fluids without compromising quality.

These pumps can also be easily cleaned and sanitized, which is critical in the food processing industry. The sanitary design ensures that there are no bacteria or contaminants left behind after the pumping process, which is essential for food safety.

The Role of Rotary Lobe Pumps in the Pharmaceutical Industry

In the pharmaceutical industry, precision and care are paramount when handling high viscosity fluids. Medications and vaccines often need to be transported in a way that prevents any degradation or contamination. Rotary lobe pumps are well-suited to these requirements, as they ensure a gentle transfer of fluids without introducing any shear or turbulence.

Moreover, Ace Lobe Pumps offer hygienic designs that meet strict pharmaceutical regulations, including the need for easy cleaning and sterilization between production batches.

Why Choose Ace Lobe Pumps?

1. Durability and Reliability

Ace Lobe Pumps are known for their robust design and long service life. These pumps are built to withstand the rigors of handling high viscosity fluids day in and day out, providing dependable performance even under challenging conditions.

2. Customization for Specific Needs

At Ace Lobe Pumps, we understand that every application is unique. That’s why we offer customizable solutions to meet the specific requirements of your fluid handling needs. Whether it’s adapting to a specific viscosity range or customizing seals for particular fluid types, our pumps are tailored to maximize your efficiency.

3. Energy Efficiency

While rotary lobe pumps are designed to handle thick liquids, they are also energy-efficient. Their positive displacement nature means they can operate at lower energy consumption levels compared to other types of pumps, helping you save on energy costs.

Maintenance Tips for Rotary Lobe Pumps

To ensure that your rotary lobe pump continues to operate at peak performance, regular maintenance is essential. Here are a few tips:

Regularly Inspect the Seals: Ensure that the seals are not worn out and are performing optimally to prevent leakage.

Lubricate the Bearings: Keep the bearings well-lubricated to avoid excessive wear and tear.

Check for Clogging: Thick fluids can sometimes clog the pump. Regularly check for any blockages to ensure smooth operation.

Clean the Pump After Use: In industries like food and pharmaceuticals, hygiene is critical. Clean your rotary lobe pump thoroughly to maintain sanitation standards.

Common Applications of Rotary Lobe Pumps

Rotary lobe pumps are highly versatile and are used in many different industries, including:

Food and Beverage: Handling products like ketchup, chocolate, honey, and oils.

Pharmaceuticals: Transporting creams, ointments, and vaccines.

Chemical Processing: Pumping polymers, adhesives, and resins.

Wastewater Treatment: Moving sludge and thick waste materials.

Conclusion

In conclusion, rotary lobe pumps are among the best solutions for efficiently handling high viscosity fluids. Their ability to provide a smooth, pulsation-free flow with minimal shear forces makes them ideal for industries such as food processing, pharmaceuticals, and chemicals. With the reliable, durable, and customizable options offered by Ace Lobe Pumps, you can ensure that your high viscosity fluid handling processes run smoothly and efficiently, without compromising quality.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.