The Essential Guide to Quantity Takeoff in Construction

Quantity takeoff is a crucial procedure in the construction industry that involves determining and measuring the quantity of material needed for an undertaking. This vital task helps lay the foundation for planning, procurement, and project scheduling, greatly impacting the project's success overall. Being aware of the specifics of quantity takeoff could assist estimators, contractors, and project managers improve their work, cut costs as well as boost the payoff of projects. This document will cover the most important aspects of quantity takeoff, their significance, the methods used, as well as excellent techniques.

Understanding Quantity Takeoff

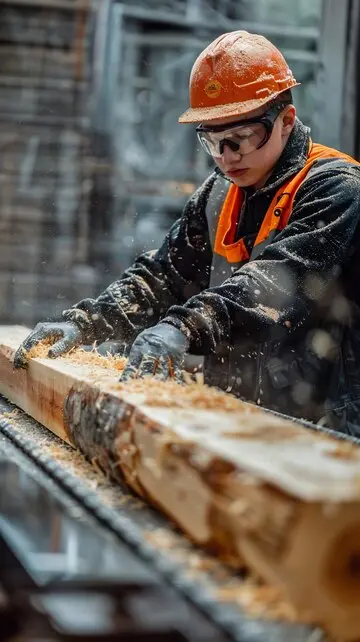

In essence, the term "quantity" takeoff refers to the procedure of Lumber Takeoff services measurements and counting all of the components needed for a construction job. This can include things such as concrete and steel, as well as lumber as well as drywall and other finishing. The process is generally completed at the beginning of construction and acts as the basis for developing accurate cost estimates and timelines for the project. An accurate quantity takeoff will ensure that every item is properly included which reduces the possibility of overruns and delays in the construction phase.

Importance of Quantity Takeoff

The importance of quantity taking for construction can't be understated. There are a variety of reasons this is an essential stage in the lifecycle of a project:

Accurate cost estimation Accurate quantity is taken off permits for exact cost estimation permitting contractors to compete and secure their projects, without having to sacrifice profitability.

Resources Management A complete understanding of the material requirements Project managers can better assign resources, and make sure that the appropriate resources are in place at the correct moment.

Minimized Loss An effective quantity cutoff can reduce waste, by making sure that the proper quantities of the materials are ordered. This could result in significant cost savings as well as promote sustainable construction practices.

With better Project Planning with exact quantities available project managers can design accurate timelines and schedules improving project efficiency and effectiveness.

More Effective Communication Quantity Takeoff offers the basis for communicating between all project partners which includes contractors, architects, and even suppliers. Transparency helps reduce the possibility of miscommunication and ensures that expectations are aligned.

Methods of Quantity Takeoff

There are a variety of techniques for performing quantity takeoffs, each of which has its pros and cons. The decision to choose a method usually is based on the complexity of the project and resources available, as well as the preference of the estimator. For example, when estimating lumber quantities, such as the 2×6 actual size, it's essential to choose a method that accurately reflects the dimensions and specifications required for the project.

Manual Takeoff The traditional way of doing this requires physically measuring and computing the quantities together with plans, blueprints as well and specifications. Although manual takeoffs are precise, they can be slow and susceptible to human mistakes. Manual takeoffs are often utilized for small projects, or estimates who favor the hands-on method.

Digital takeoff As technology advances, technology, a large number of estimators utilize digital tools and programs for taking off quantities. They allow users to take digital blueprints into their computer and then automatically determine quantities using the measurements. Digital takeoff software is able to greatly improve the speed of calculations and minimize errors, making it an ideal choice for large-scale tasks.

HTML0-based Building Information Modeling (BIM) BIM is the most cutting-edge method that combines digital models and detailed information on materials and quantity. Through together BIM, estimation experts can visualize their project in 3D and make it simpler to pinpoint potential issues and more accurately assess the material requirements. It is becoming more popular in the construction industry for its ability to improve collaboration as well as raise efficiency.

Leading Practices for Quantity Takeoff

To warrant the accuracy and efficiency of your process for taking off quantities, think about applying these accurate techniques:

Get familiar with Project Plans: Before taking off, you must carefully review the drawings and specifications. Being aware of the concept and specifics will allow you to find the necessary materials as well as the required quantities.

Organize the Takeoff Process The takeoff process can be broken down into smaller parts. Your takeoff into smaller sections by focusing on a specific area or element at a given moment. A structured process will help keep you organized and decrease your chances of ignoring important items.

Utilize Standardized units when measuring or reporting quantity, make sure to make use of standardized units to warrant consistency. This helps to measure quantities, and also communicate between team members as well as suppliers.

Document everything Maintain detailed documentation of the measures, calculations, and other assumptions during the taking-off process. These records will be used as a guide for the future and bring an easy trace for the accountability.

Double-check Your Work After the takeoff has been completed make sure you look over your calculation and measurement. Any errors can have a significant impact in terms of project expenses and deadlines therefore it is essential to assure the accuracy of your calculations before finalizing your takeoff.

Collaboration with Team Members Connect with other stakeholder groups including engineers, architects, and project managers during the process of taking off. Collaboration helps boost communication. Assists in identifying potential problems earlier, and makes sure that all parties are in the same boat.

Remain informed on Industry trends The industry of construction continues to evolve and the latest materials, techniques, and methodologies emerging frequently. Becoming aware of the latest trends will allow you to adapt your processes for taking off, and help you maintain an edge in the market.

Conclusion

Quantity Takeoff is a crucial element of construction that provides the basis for an exact estimate of costs resources management, cost estimation, and planning of the project. Through understanding the techniques and perfect methods that are associated with quantity takeoff, construction experts can improve their effectiveness, cut costs as well as increase the outcome of their projects. While continuing to adopt technology and innovations keeping up-to-date and agile is crucial to success with regard to quantity takeoff as well as overall construction management.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.