The Evolution and Importance of Steel Components

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

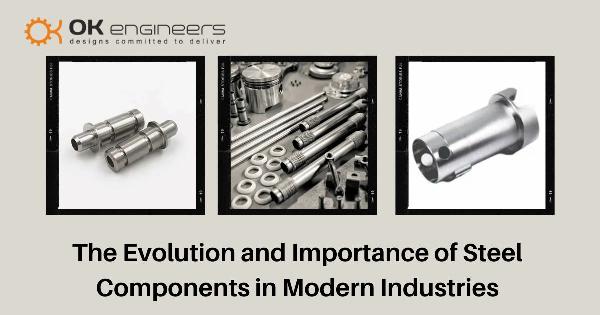

In today's rapidly advancing industrial landscape, Steel Components play a crucial role in various sectors, including construction, automotive, aerospace, and manufacturing. Known for their strength, durability, and versatility, steel components have become integral to modern engineering practices. This blog delves into the significance of steel components, their various applications, and how brands like OK Engineers are leading the way in providing high-quality steel solutions.

Understanding Steel Components

Steel components refer to any part or element made from steel, utilized in construction and manufacturing processes. These components can vary significantly in size, shape, and function, ranging from small nuts and bolts to large structural beams. The versatility of steel allows it to be customized for various applications, making it a preferred material in many industries.

Key Properties of Steel

Strength and Durability: Steel is renowned for its exceptional tensile strength, allowing it to withstand heavy loads and harsh environments without compromising structural integrity.

Corrosion Resistance: Many steel components are treated or alloyed with other materials to enhance their resistance to rust and corrosion, extending their lifespan.

Cost-Effectiveness: Steel is often more affordable compared to other materials, making it an economical choice for manufacturers and builders alike.

Sustainability: Steel is highly recyclable, contributing to environmental sustainability. It can be repurposed without losing its properties, reducing waste in industrial processes.

Applications of Steel Components

Steel components are used across a wide array of industries, showcasing their versatility and importance:

1. Construction and Infrastructure

Steel is a primary material in construction, used for framing, beams, columns, and reinforcement bars. Its strength-to-weight ratio makes it ideal for skyscrapers, bridges, and other structures where stability is crucial. The use of steel components helps engineers design safer and more durable buildings.

2. Automotive Industry

In the automotive sector, steel components are essential for the structural integrity of vehicles. From chassis to engine parts, the strength of steel ensures that cars can endure various stresses while maintaining safety standards. Moreover, innovations in steel technology have led to lighter and stronger components, improving fuel efficiency.

3. Aerospace Applications

The aerospace industry relies heavily on high-strength steel components for aircraft and spacecraft construction. These components must meet stringent safety regulations while providing the necessary strength and performance under extreme conditions. Companies like OK Engineers are at the forefront of producing specialized steel components that meet these rigorous standards.

4. Manufacturing and Machinery

Steel components are fundamental in the manufacturing sector, used in machinery, tools, and equipment. From conveyor belts to precision-engineered parts, steel provides the durability and reliability needed for efficient production processes.

The Role of OK Engineers in Steel Component Manufacturing

OK Engineers is a renowned brand in the manufacturing of steel components, dedicated to delivering high-quality products tailored to meet industry standards. With years of experience, they specialize in producing a wide range of steel components, including:

Custom Fabrications: OK Engineers offers tailored solutions, providing customized steel components designed to meet specific client requirements.

Quality Assurance: The company prioritizes quality control, ensuring that all steel components undergo rigorous testing and inspection to meet international standards.

Innovative Solutions: By investing in advanced technology and techniques, OK Engineers consistently develops innovative steel solutions that enhance performance and efficiency in various applications.

Commitment to Sustainability

In an era where sustainability is paramount, OK Engineers adopts eco-friendly practices in their manufacturing processes. By utilizing recycled steel and implementing energy-efficient production methods, they contribute to reducing the environmental impact of steel manufacturing.

Future Trends in Steel Component Manufacturing

As industries continue to evolve, the demand for advanced steel components will rise. Several trends are shaping the future of steel component manufacturing:

1. Increased Use of High-Strength Steel

With the need for lightweight yet durable materials, high-strength steel is gaining popularity across various sectors. Manufacturers are exploring new alloys and treatments to enhance performance, ensuring that steel components meet the evolving demands of modern applications.

2. Automation and Smart Manufacturing

The rise of Industry 4.0 has led to the integration of automation and smart technologies in steel component manufacturing. This shift allows for improved precision, reduced production times, and enhanced quality control, positioning brands like OK Engineers as leaders in adopting innovative practices.

3. Sustainable Practices

As environmental concerns grow, manufacturers are focusing on sustainable practices, including the use of renewable energy sources and eco-friendly materials. The steel industry is gradually moving towards circular economy principles, emphasizing recycling and waste reduction.

Conclusion

Steel components are indispensable in modern industries, providing the strength, durability, and versatility required for various applications. Brands like OK Engineers are pivotal in advancing steel component manufacturing, ensuring high-quality products that meet the demands of today's market. As industries continue to innovate, the future of steel components looks promising, driven by technological advancements and a commitment to sustainability. Embracing these changes will allow manufacturers and engineers to harness the full potential of steel components, shaping the future of engineering and construction.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.