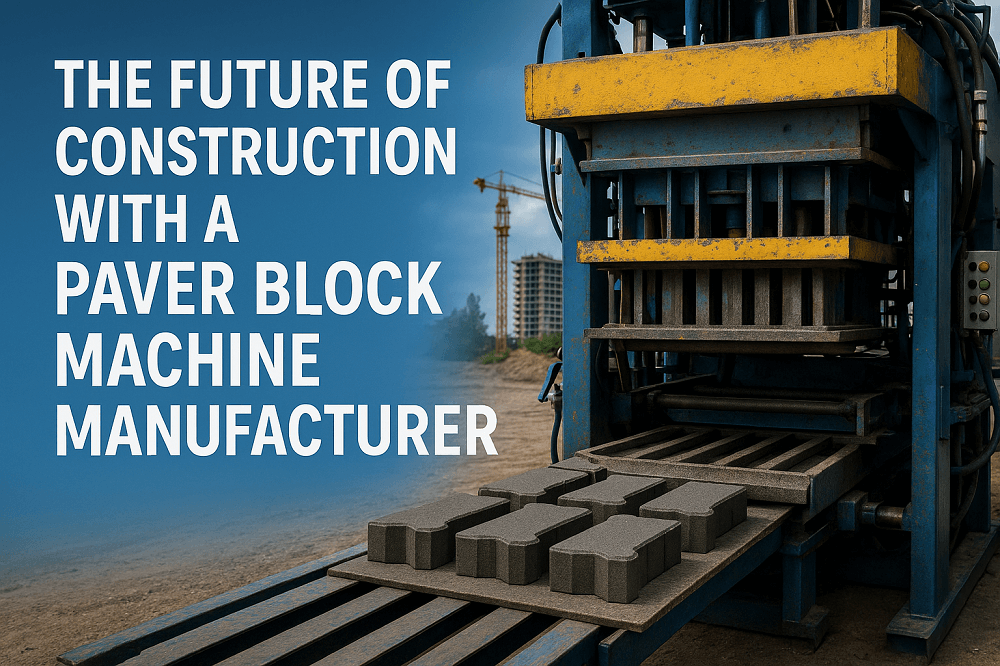

The Future of Construction with a Paver Block Machine Manufacturer

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The construction industry is changing fast. Builders now want solutions that are faster, stronger, and more cost-effective. One key innovation is the paver block machine. And behind every powerful machine is a trusted paver block machine manufacturer.

In this blog, we’ll explore how these manufacturers are shaping the future of construction. Whether you run a construction company or a block-making unit, this guide will help you understand the impact of modern machines on your business.

1. What is a Paver Block Machine?

A paver block machine is used to produce concrete blocks, interlocking tiles, and paving bricks. These blocks are used in sidewalks, driveways, roads, and outdoor areas.

The machine helps automate the process. It can produce large volumes of blocks quickly and with high accuracy. Machines come in different types—manual, semi-automatic, and fully automatic.

2. The Role of a Paver Block Machine Manufacturer

A paver block machine is only as good as the company that makes it. The paver block machine manufacturer designs, builds, and supplies machines to clients. A good manufacturer also provides after-sales support, training, and spare parts.

They ensure that the machine is reliable, safe, and durable. Leading manufacturers focus on innovation, helping the construction industry work faster and smarter.

3. Benefits of Using Modern Paver Block Machines

Here’s how modern paver block machines are changing construction:

Faster Production: Machines can make hundreds of blocks per hour.

Consistent Quality: Uniform size and strength in every block.

Cost Savings: Less labour needed, lower material waste.

Eco-Friendly: Many machines support fly ash and recycled materials.

Durability: Strong blocks reduce repair and maintenance costs.

4. Why the Right Manufacturer Matters

Choosing the right paver block machine manufacturer is important. A well-known brand offers many advantages:

Advanced Technology: Latest features for better performance.

Training and Setup: Help with installation and operation.

Spare Parts Support: Quick supply of parts when needed.

Long-Term Value: Machines last longer with good service.

Customization: Get machines suited to your needs.

A poor-quality machine can lead to breakdowns, poor blocks, and losses. That’s why picking the right partner is key.

5. Trends Shaping the Future of Block Manufacturing

The future is bright for paver block machines. Here are some trends to watch:

a. Automation

Fully automatic machines are now more popular. They reduce manual work and increase productivity. In the future, we may see machines with self-diagnosis and smart sensors.

b. Smart Controls

New machines use PLC-based systems and touchscreens. These controls help operators monitor the machine and fix problems faster.

c. Eco-Friendly Materials

Manufacturers now design machines that work with fly ash, slag, and other waste. This helps reduce environmental harm and promote green building.

d. Custom Block Designs

Customers want unique patterns. Machines now support various mould types, allowing block makers to offer more options.

e. Energy Efficiency

Modern machines use less power. This lowers energy costs and helps the environment.

6. Industries Benefiting from Paver Block Machines

Many sectors now rely on block machines:

Construction Firms: For building pathways, roads, and landscapes.

Real Estate Developers: To design elegant outdoor areas.

Municipal Projects: For footpaths, drainage, and public spaces.

Government Schemes: For housing and infrastructure development.

Startups in Manufacturing: New businesses find it easy to begin with semi-automatic machines.

7. Choosing the Right Machine for Your Needs

There are many options in the market. To choose the best one, consider:

Production Capacity: How many blocks per hour?

Type of Blocks: Interlocking, solid, or hollow?

Automation Level: Manual, semi-auto, or fully auto?

Space Required: Machines come in different sizes.

Power Use: Pick energy-efficient models.

Budget: Balance cost and features wisely.

A good paver block machine manufacturer will guide you through all these points.

Final Thoughts

The future of construction is smart, fast, and green. A paver block machine manufacturer plays a big role in this change. With advanced machines, you can produce better blocks in less time, cut costs, and meet modern demands.

If you're planning to enter the block manufacturing business or upgrade your existing setup, now is the time. Look for a reliable manufacturer who offers quality, support, and innovation.

By choosing wisely, you build a stronger foundation—not just for blocks, but for your business too.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.