The Importance of Mechanical Detailing Services in Engineering Projects

Precision in engineering begins with accurate documentation. Mechanical detailing services provide the technical foundation that transforms concepts into reality, guiding every step from design to manufacturing. These services create the detailed drawings that machinists, welders, and assembly teams rely on to build components correctly the first time. Without proper mechanical detailing, even the best designs can lead to costly errors. For instance, imagine a custom engine part that doesn't fit during assembly or structural steel beams that require modifications on-site. These preventable issues highlight why mechanical detailing is not just helpful – it's essential for any project demanding accuracy and efficiency.

What Are Mechanical Detailing Services?

Mechanical detailing services involve creating detailed technical drawings and documentation for mechanical components and assemblies. These drawings include:

- Precise dimensions and tolerances: Ensuring that every component fits perfectly within the assembly. This includes specifying the exact measurements and allowable deviations to ensure compatibility with other parts.

- Material specifications: Detailing the type of materials to be used, such as steel grades, finishes, and coatings. This information is crucial for ensuring that the components can withstand the intended loads and environmental conditions.

- Assembly instructions: Providing clear guidelines on how to assemble parts, including bolting, welding, and fastening methods. These instructions help ensure that the assembly process is efficient and that the final product meets quality standards.

- Manufacturing notes: Offering guidelines for machining and fabrication processes to ensure consistency. This may include specific machining techniques, tolerances, and surface finish requirements.

- Bill of Materials (BOM): Listing all components and materials required for procurement. A well-structured BOM helps streamline the purchasing process and ensures that all necessary materials are available when needed.

Using CAD (Computer-Aided Design) and BIM (Building Information Modeling) tools, mechanical detailers convert rough sketches or 3D models into production-ready drawings that machinists, fabricators, and engineers rely on for accuracy.

Why Are Mechanical Detailing Services Essential?

- Ensures Accuracy & Reduces Errors: Mistakes in manufacturing can cost thousands in rework. Mechanical drafting services eliminate guesswork by providing exact measurements, tolerances, and material callouts. This prevents misalignment, improper fits, and assembly issues, ultimately saving time and resources.

- Enhances Manufacturing Efficiency: With clear, standardized engineering drawings, production teams can work faster with fewer interruptions. Automated CNC machining, laser cutting, and welding rely on precise CAD models to function correctly, streamlining the manufacturing process and reducing lead times.

- Facilitates Better Communication: Engineers, fabricators, and contractors must all work from the same specifications. Shop drawings act as a universal language, reducing misinterpretations and simplifying collaboration in global teams where language barriers may exist. This clarity helps ensure that everyone involved in the project is on the same page.

- Compliance with Industry Standards: Different industries (ASME, ISO, AWS, ANSI) have strict drafting standards. Mechanical detailers ensure drawings meet regulations for safety (load-bearing structures, pressure vessels), durability (corrosion resistance, fatigue analysis), and quality control (inspection points, testing requirements). Compliance with these standards is critical for ensuring the safety and reliability of the final product.

- Cost Savings in Production: Proper detailing reduces material waste through optimized nesting in laser/plasma cutting, minimizes assembly errors leading to fewer rejected parts and delays, and avoids expensive rework through precision in GD&T (Geometric Dimensioning & Tolerancing). These cost savings can significantly impact the overall budget of a project.

Types of Mechanical Detailing Services

Depending on project needs, companies may outsource various types of mechanical detailing services, including:

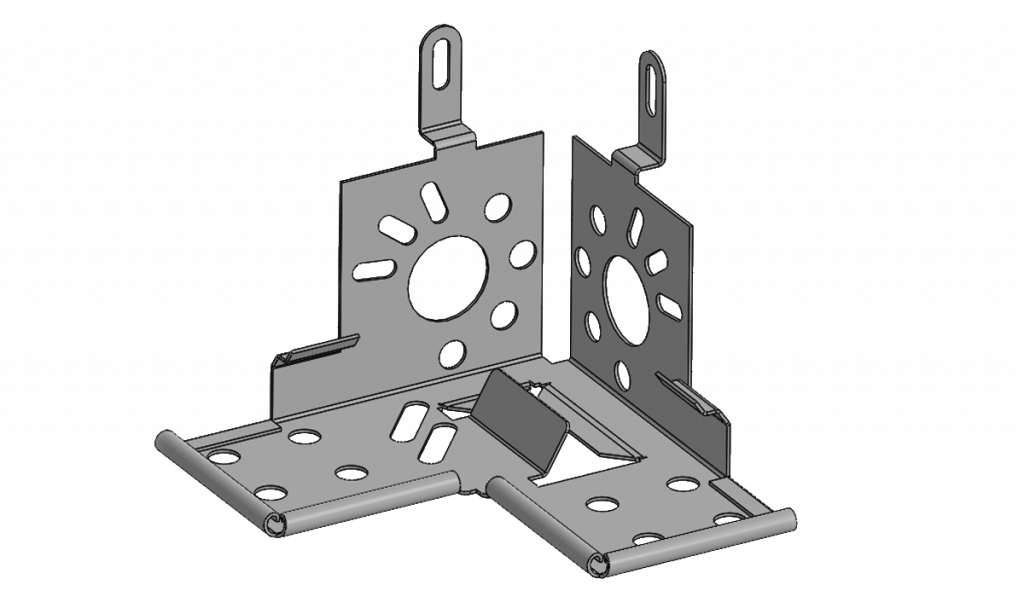

- 3D Mechanical Drafting: Ideal for prototyping, simulation, and complex assemblies, commonly used in automotive, aerospace, and industrial equipment sectors. This service allows for visualization of components in a three-dimensional space, facilitating better design decisions.

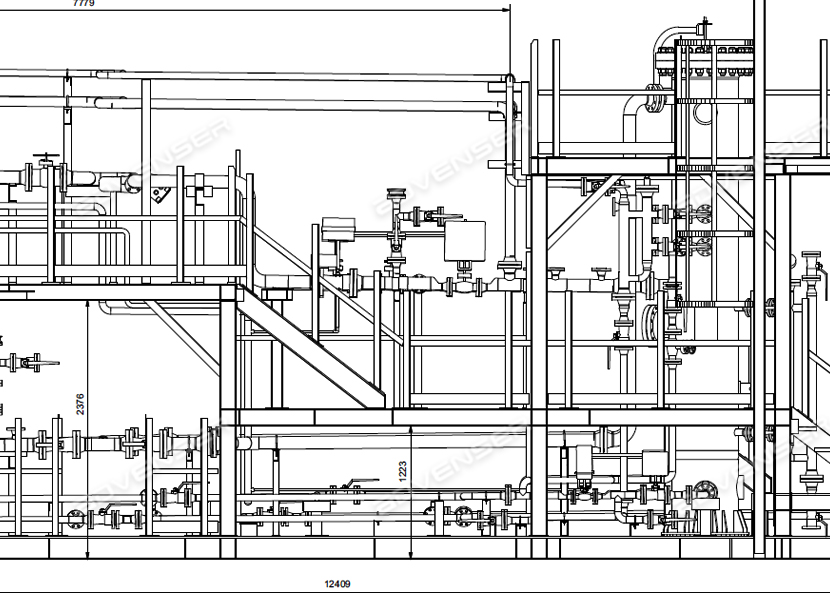

- Fabrication Drawings: Covering sheet metal, structural steel, and piping layouts, these drawings include bend allowances, weld symbols, and machining instructions. Fabrication drawings are essential for ensuring that components are manufactured accurately and efficiently.

- Assembly Drawings: Illustrating how parts fit together through exploded views and BOMs, critical for large-scale machinery and modular structures. These drawings help assembly teams understand the relationships between different components and the overall assembly process.

- As-Built Drawings: Updated documentation post-construction, ensuring maintenance teams have accurate records for future reference. As-built drawings reflect any changes made during construction, providing a reliable resource for ongoing maintenance and modifications.

Who Needs Mechanical Detailing Services?

These services benefit a wide range of industries, including:

- Manufacturers: In sectors such as automotive, aerospace, and energy, where precision is paramount. Manufacturers rely on accurate detailing to produce high-quality components that meet stringent performance standards.

- Fabrication Shops: Specializing in structural steel, piping, and sheet metal fabrication. These shops depend on detailed drawings to ensure that their production processes run smoothly and efficiently.

- MEP Contractors: Focusing on mechanical, electrical, and plumbing systems. MEP contractors require precise detailing to coordinate the installation of complex systems within buildings.

- Engineering Firms: Engaged in product design and development. Engineering firms benefit from mechanical detailing services to ensure that their designs are manufacturable and meet client specifications.

- Industrial Plants: In need of maintenance and retrofitting services. Accurate documentation is essential for maintaining and upgrading existing equipment and systems.

Why Engineering Projects Need Mechanical Detailing

- Clarity in Communication: Mechanical detailing translates engineers' concepts into a universal technical language. The drawings specify exactly how components should be manufactured and assembled, eliminating guesswork for fabricators working with complex geometries or tight tolerances.

- Cost and Time Savings: Accurate detailing reduces material waste and prevents assembly errors that can cause project delays. For example, proper sheet metal flat patterns account for bend allowances, ensuring parts form correctly without trial-and-error adjustments. The upfront investment in quality detailing often pays for itself by avoiding these manufacturing headaches.

- Compliance and Safety: Detailed drawings incorporate industry standards like ASME Y14.5 and ISO specifications. This ensures critical components meet strength, durability, and safety requirements, which is particularly important for load-bearing structures, pressure vessels, and machinery subjected to significant forces.

Key Applications

- Industrial Equipment: Providing detailed assembly instructions for complex machinery, ensuring that all components fit and function as intended.

- Structural Projects: Ensuring precise connections for steel frameworks, which is vital for the integrity and safety of buildings and other structures.

- HVAC and Piping: Offering clear routing and component specifications, which are essential for the efficient operation of heating, ventilation, and air conditioning systems.

- Product Development: Delivering manufacturing-ready part drawings that facilitate smooth production and help bring new products to market quickly.

The Detailing Process

Skilled detailers use CAD software to develop drawings that include:

- Dimensional accuracy: Achieving precision to thousandths of an inch, which is critical for ensuring that components fit together correctly.

- Material specifications and finishes: Clearly outlining the required materials and surface treatments to ensure durability and performance.

- Welding symbols and connection details: Providing essential information for assembly, including the types of welds to be used and the locations of connections.

- Manufacturing notes for fabricators: Ensuring that all necessary guidelines are included for production, helping to streamline the manufacturing process.

Conclusion

Mechanical detailing services bridge the gap between design and production, ensuring engineering projects run smoothly. By outsourcing to experienced detailers, businesses gain:

- Error-free manufacturing: Reducing the likelihood of costly mistakes and ensuring that components are produced to the highest standards.

- Faster approvals & production: Streamlining the workflow from design to manufacturing, allowing projects to move forward more quickly.

- Regulatory compliance: Meeting industry standards and safety regulations, which is essential for maintaining the integrity of the final product.

- Cost-effective material usage: Minimizing waste and optimizing resources, which can significantly impact the overall budget of a project.

- Long-term documentation for maintenance: Providing accurate records for future reference, which is crucial for ongoing maintenance and modifications.

Whether you're launching a new product or optimizing fabrication processes, high-quality mechanical drafting services are a smart investment. Partner with experts who deliver precision, efficiency, and compliance to ensure your projects succeed. By leveraging the expertise of skilled mechanical detailers, businesses can enhance their operational efficiency, reduce costs, and ultimately achieve better project outcomes.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.