The India 3D Printer Market Growth, Top Players and Outlook

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

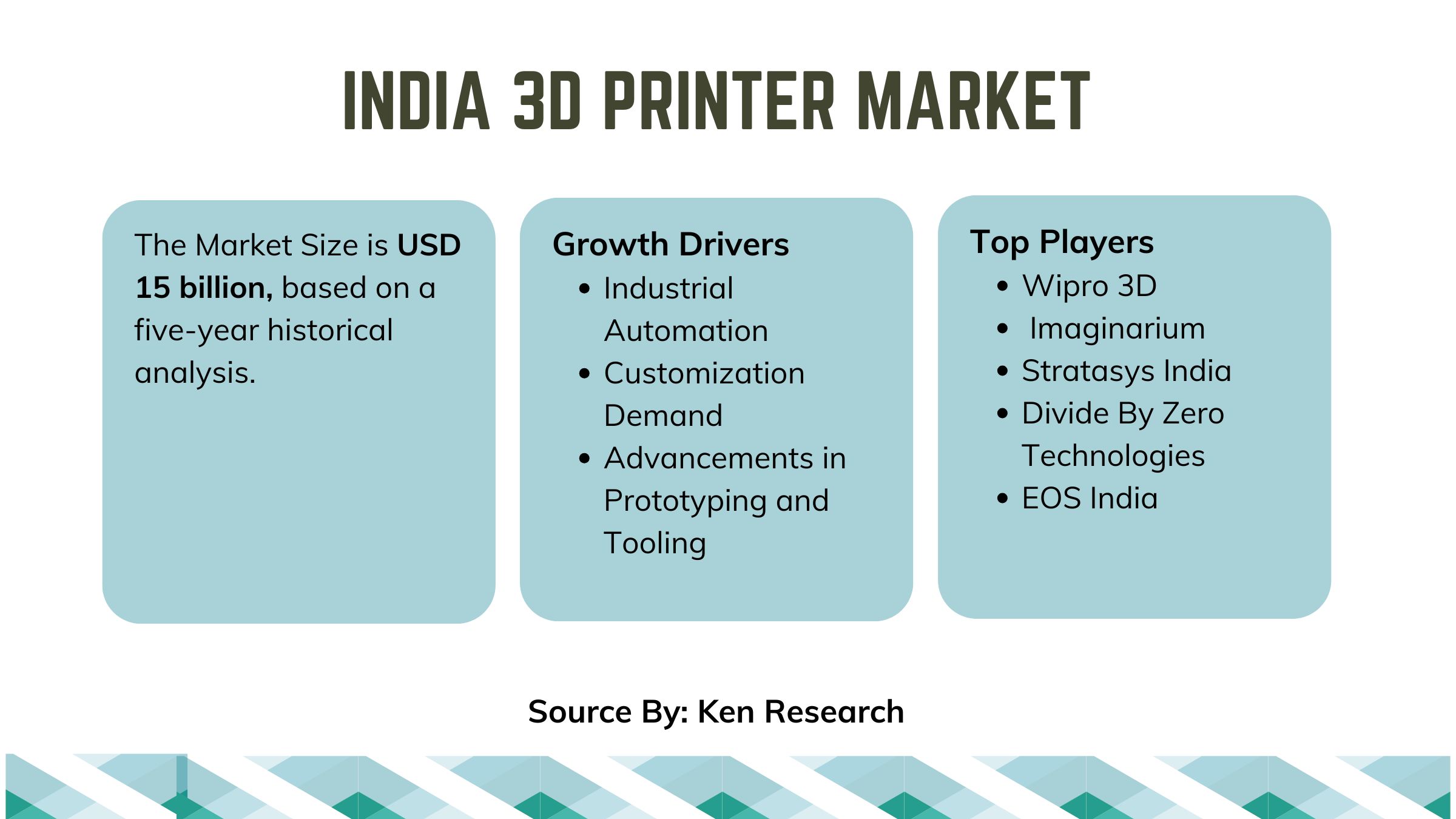

The India 3D printer market is currently valued at USD 15 billion, demonstrating strong growth over the past five years. This expansion is driven by rapid advancements in manufacturing, increased adoption of 3D printing technology in key industries, and government initiatives promoting additive manufacturing. Sectors such as healthcare, automotive, and aerospace are at the forefront of 3D printing adoption, fueling market growth. Bengaluru, Mumbai, and Pune are leading cities in the industry due to their strong industrial ecosystems and research capabilities.

India 3D Printer Market Growth

Several factors are propelling the expansion of India 3D printing market:

- Government Initiatives: The Government of India's National Strategy on Additive Manufacturing (2022) aims to establish India as a global 3D printing hub, with objectives such as increasing the country’s share in the global market to 5% by 2025 and supporting 100 new startups.

- Industrial Automation: The rise of automation in industries like automotive and electronics has boosted demand for 3D printing for rapid prototyping and tooling.

- Customization Demand: Growing consumer demand for personalized products, particularly in healthcare (custom prosthetics, dental implants) and automotive (bespoke vehicle components), is driving 3D printing adoption.

- Advancements in Prototyping and Tooling: The ability to develop high-quality prototypes quickly and at a lower cost is increasing reliance on 3D printing across industries.

Top Players in the India 3D Printer Industry

The competitive landscape consists of both local and international players. Major contributors include:

- Wipro 3D (Established: 2014, HQ: Bengaluru) – A leader in industrial 3D printing and metal additive manufacturing.

- Imaginarium (Established: 2009, HQ: Mumbai) – Specializing in jewelry and industrial-grade 3D printing solutions.

- Stratasys India (Established: 1998, HQ: Bengaluru) – A key player offering high-performance 3D printing solutions for various sectors.

- Divide By Zero Technologies (Established: 2013, HQ: Navi Mumbai) – Focused on developing affordable 3D printing solutions for SMEs.

- EOS India (Established: 2000, HQ: New Delhi) – Specializing in industrial-grade metal and polymer 3D printing.

These companies are expanding their market presence through strategic partnerships, innovative product launches, and investments in research and development.

Key Trends Shaping the India 3D Printer Market

The India 3D printer market is witnessing several emerging trends that are shaping its future trajectory:

- Growth in Metal 3D Printing: Industries such as aerospace and automotive are increasingly adopting metal 3D printing for high-precision, lightweight component production.

- Expansion of Medical Applications: 3D printing is being used extensively in healthcare for dental implants, orthopedic solutions, and bioprinting applications.

- Local Manufacturing Initiatives: Programs such as "Make in India" are encouraging domestic production of 3D printing hardware and materials, reducing dependency on imports.

- AI and Machine Learning Integration: Advanced AI-driven 3D printing solutions are enhancing automation and efficiency, improving production speed and material optimization.

Future Outlook

Over the next five years, the India 3D printer market is expected to experience significant growth, driven by:

- Advancements in Printing Materials: The development of new materials, including biodegradable and high-performance polymers, will open new application areas.

- Increase in Research & Development: Investments in R&D are expected to drive innovations, particularly in bioprinting and industrial-grade 3D printing.

- Aerospace and Defense Expansion: The adoption of 3D printing for lightweight, complex components will accelerate, driven by India’s increasing defense manufacturing capabilities.

- Government Support: Policies focused on reducing import duties on 3D printing materials and increasing domestic production will further propel market expansion.

Conclusion

The India 3D printer industry is on a robust growth trajectory, supported by industrial adoption, government policies, and technological advancements. While challenges such as high initial costs and limited material availability persist, ongoing investments and policy interventions are expected to mitigate these hurdles. As 3D printing technology continues to evolve, its integration into key industries will further solidify India’s position as a leader in additive manufacturing.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.