Zapier Automation – Automate Publishing. Free Your Time!

Zapier Automation – Automate Publishing. Free Your Time!

The Invisible Shield of Glass: Unveiling the Defining Role of Edge Finishing

Written by Phano » Updated on: June 17th, 2025

From the sleek, reflective surfaces in our bustling cityscapes to the resilient panes protecting our homes against the elements, glass's role in modern architecture, design, and everyday safety cannot be overstated. However, what's often overlooked is the intricate detail that turns a raw glass sheet into a robust, functional, and aesthetic component—the critical step of edge finishing. This oft-forgotten process plays a defining role in the glass's performance and safety. Exploring the depths of edge finishing, we uncover the hidden world where craftsmanship marries technology to create a fundamental yet unseen shield that defines our interaction with glass.

The Integrity in the Invisible

You may not give much thought to the unassuming, straight edge of the window by your desk or the gentle curve of the glass countertop at your favourite cafe. Yet, these edges, treated with precision and care, hold the key to the glass's long-term durability and, in some cases, structural soundness. But what exactly is edge finishing, and why is it crucial?

Defining the Edge Finish

Glass Edge finishing refers to the process of treating the sharp, raw edges of cut glass to render them smooth, uniform, and safe for handling. This may involve techniques such as grinding, sanding, and polishing, which not only enhance the glass's appearance but also prevent edge chipping and surface stress that could lead to fractures.

The Role of Finish in Glass Integrity

An unpolished or poorly finished glass edge is more susceptible to flaws like 'fissures'—pre-existing micro-cracks that can propagate under stress, potentially leading to catastrophic failure. By applying the right edge finishing, glassmakers diminish the likelihood of these imperfections, bolstering the glass's overall structural integrity.

The Safety Margin

When we speak of safety in relation to glass, the conversation often gravitates towards tempered glass and laminates—rightfully so, given their capacity to reduce hazards upon breakage. Yet, edge finishing plays a critical—and often undervalued—part in the safety equation.

Mitigating the Risk of Accidents

Properly finished edges ensure that glass products, even in standard annealed form, are safer to handle. Smooth, uniform edges reduce the risk of accidental cuts and scrapes during production, transportation, installation, and everyday use. For applications like shower doors or glass tables—where close interaction is expected—the safety improvement is crucial.

Longevity as a Safety Measure

In the architectural arena, where large, unsupported glass surfaces are the norm, the tempered edge finishing becomes even more significant. A properly tempered and finished edge can significantly reduce the risk of 'spontaneous breakage,' safeguarding against sudden, unprovoked glass shattering, which can be perilous in high-traffic or high-occupancy areas.

Meeting Standards and Regulations

The importance of edge finishing isn't just a matter of best practices or manufacturer warranties; it’s legally enforceable in many cases. Across the globe, stringent standards and building codes dictate the minimum edge treatment requirements for the different glass types and applications.

The Compliance Conundrum

Architects, builders, and glass manufacturers must stay abreast of local, national, and international codes that stipulate the permissible surface flaws and demand specific edge finishes for particular applications. These guidelines not only ensure a baseline of safety but also reflect the industry's collective understanding and evolving techniques in mitigating glass-related risks.

Pushing the Compliance Envelope

In some instances, industry leaders may exceed the stipulated requirements, adopting more rigorous edge finishing to enhance their products' quality and longevity. This proactive approach can lead the charge in setting new standards, as safety and innovation go hand in hand.

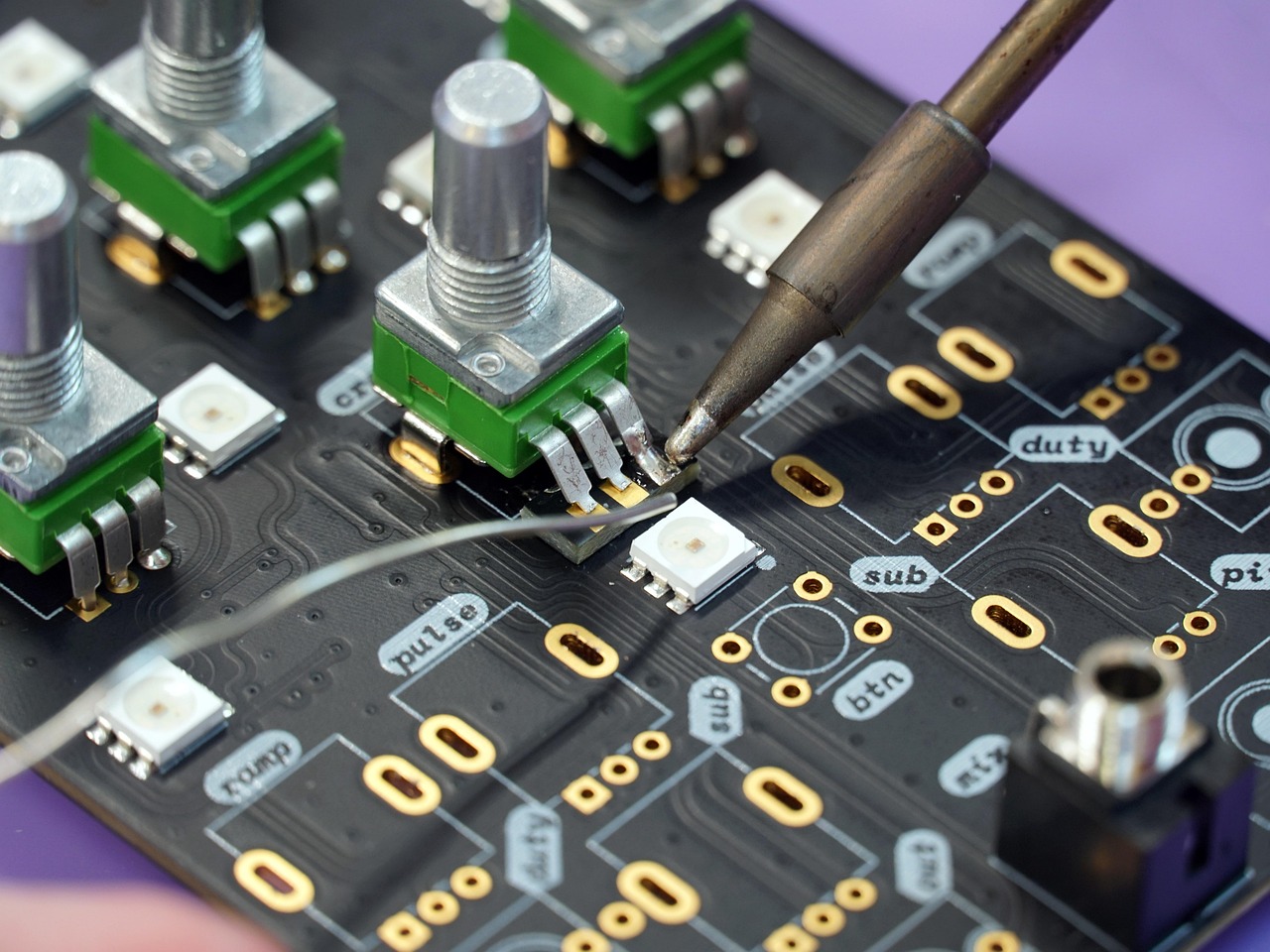

Innovative Techniques and Technologies

The art of edge finishing is not a stagnant practice—it evolves with material advancements and technological breakthroughs. Today, modern tools and machinery are pushing the boundaries of what's achievable, allowing for precision that was once inconceivable.

Precision in Motion

Computer Numerical Control (CNC) machines are revolutionizing glass fabrication, enabling intricate detailing and edge profiles that were previously unattainable. With these machines, manufacturers can customize edges to meet specific aesthetic and safety requirements with unmatched accuracy and repeatability.

The 'Polished' Frontier

Advancements in polishing compounds and abrasive materials are contributing to smoother, more durable edge finishes. From diamond beveling to chemical strengthening and post-treatment processes, glass edges are now under-going a level of refinement that delivers both function and finesse.

Looking Beyond the Edge

Edge finishing is more than just a technicality in glass production—it embodies a commitment to quality, craftsmanship, and user safety. By recognising and valuing the effort that goes into this invisible art, we not only gain a deeper appreciation for our glass surroundings but also ensure our ongoing interaction with this vital material is as risk-free and rewarding as possible.

For consumers, it means making informed choices about the glass products they use and install, looking not just at glazing type or thickness but also examining the subtler details such as edge quality. For glass professionals, it's about continuing to refine their practices, adopt new technology, and elevate their craft to ensure every finished edge is a testament to their dedication to safety and excellence.

In the grand mosaic of glass's role in our daily lives, edge finishing remains a piece often understated but one that solidifies the entire picture. It's the unsung hero safeguarding the modern elegance and utility that glass brings to our world.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.