The Lifecycle of a Mass Timber Building: From Sawmill to Skyline

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Building the Future with Wood

In today’s push for sustainable and innovative construction, mass timber has emerged as a game-changing material. With its natural aesthetics, structural strength, and low environmental impact, it’s quickly becoming a favorite in modern architecture. But have you ever wondered how a towering timber structure comes to life—from its roots in the forest to a striking presence on a city skyline? Let’s take a detailed look at the journey of a mass timber building and explore how it evolves through every stage of its lifecycle.

What is Mass Timber?

Mass timber refers to a category of engineered wood products that are designed for structural applications. Unlike traditional stick-frame wood construction, mass timber involves large, solid panels or beams made from layers of wood glued or fastened together. Common types include Cross-Laminated Timber (CLT), Glue-Laminated Timber (Glulam), and Nail-Laminated Timber (NLT). These products offer impressive strength, fire resistance, and dimensional stability, making them suitable for mid- to high-rise buildings. What sets mass timber apart is its ability to combine modern performance with sustainability, all while adding a natural aesthetic to urban architecture.

1. Sourcing the Raw Material: Sustainable Forestry

The journey of mass timber begins in responsibly managed forests. These forests, often located in North America or Europe, are certified by organizations like the FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) to ensure sustainable harvesting.

Only mature trees are selected for cutting, allowing the forest to regenerate naturally. The emphasis is on maintaining biodiversity and long-term forest health. This sustainable sourcing makes mass timber one of the most environmentally friendly materials in modern construction.

2. Processing at the Sawmill: From Logs to Laminates

Once harvested, logs are transported to sawmills where they’re cut into dimensional lumber. The type of wood used varies—commonly spruce, pine, or fir—but the goal is always to produce straight, uniform boards free of major defects.

The magic of mass timber lies in engineered wood products like:

Cross-Laminated Timber (CLT): Layers of wood boards glued at 90-degree angles for strength and dimensional stability.

Glue-Laminated Timber (Glulam): Stacked and glued parallel laminations used for beams and columns.

Nail-Laminated Timber (NLT) and Dowel-Laminated Timber (DLT): Other variants using nails or dowels instead of adhesives.

At the mill, these products are engineered using high-strength adhesives, precision machinery, and rigorous quality control. They are pressed under heat and pressure to create large, prefabricated panels that can span wide distances—perfect for floors, walls, and roofs.

3. Design and Prefabrication: Digital Meets Timber

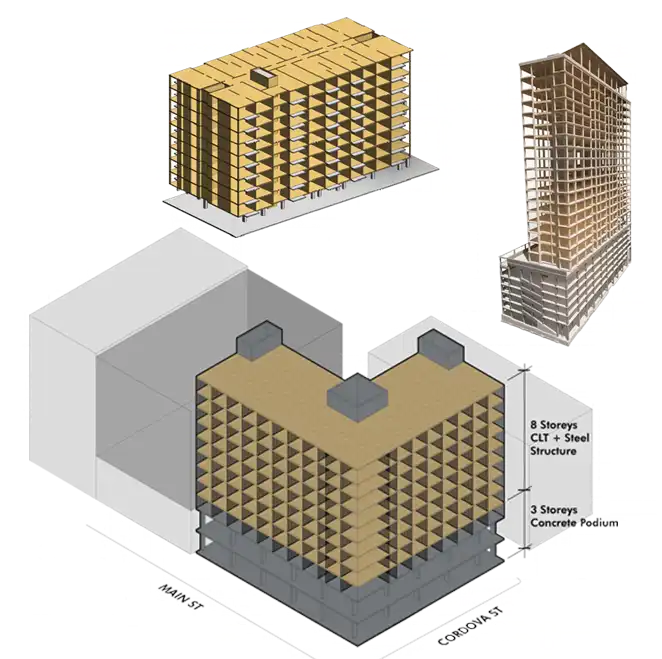

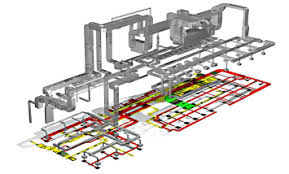

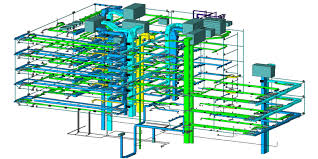

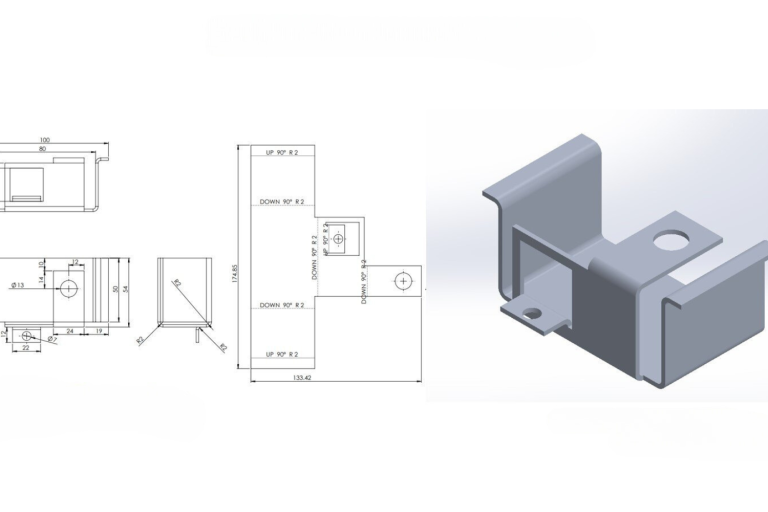

After processing, mass timber enters the digital realm. Architects and engineers use Building Information Modeling (BIM) to plan every detail of the structure. BIM allows for precise modeling of each panel, opening, joint, and connection—down to the millimeter.

Once finalized, digital plans are sent to fabrication facilities where CNC (computer numerical control) machines cut, drill, and finish each component. Openings for windows, doors, electrical conduits, and plumbing are pre-cut in the factory. This prefabrication reduces waste, speeds up construction, and ensures accuracy.

4. Transportation and Logistics: Moving Giant Panels

Mass Timber components are large but surprisingly lightweight compared to steel or concrete. This makes transportation more efficient and less carbon-intensive. The prefabricated panels are loaded onto trucks and delivered directly to the construction site.

Timing is key—logistics must align with the construction sequence to minimize storage on-site. Often, panels arrive just in time to be lifted into place by cranes, further speeding up the building process.

5. On-Site Assembly: Fast and Quiet Construction

Construction with mass timber is a game-changer. Since panels are prefabricated, the building process is fast, clean, and quiet. There's less need for on-site cutting, welding, or heavy machinery, which reduces noise and disruption in urban areas.

Using cranes, construction teams assemble the building like a 3D puzzle—panel by panel, level by level. Mass timber’s light weight allows for rapid installation, and because it’s dry construction, it’s not as weather-sensitive as concrete. Entire floors can be installed in days instead of weeks.

6. Finishing Touches: Aesthetics and Functionality

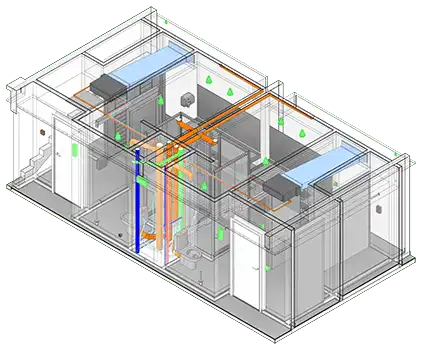

Once the structure is in place, finishes are added—cladding, windows, insulation, and internal systems like HVAC and electrical. But unlike traditional construction, the wood itself often remains exposed.

Mass timber interiors bring warmth, character, and natural beauty to a space. Beyond aesthetics, the exposed wood also contributes to occupant well-being, offering a biophilic environment that can reduce stress and enhance productivity.

7. Performance and Sustainability: Living the Green Life

Mass timber buildings are energy-efficient, carbon-friendly, and resilient. The wood acts as a carbon sink, storing CO₂ absorbed during the tree’s lifetime. Compared to steel or concrete, the embodied carbon in timber is drastically lower.

Additionally, mass timber panels offer excellent thermal insulation and can be paired with green technologies like solar panels and passive design systems. The result? A building that performs well, feels good, and helps the environment.

8. End of Life: Reuse, Recycle, or Regrow

One of the most exciting aspects of mass timber is what happens at the end of a building’s lifecycle. Mass timber can be disassembled and reused, giving the materials a second life in other projects.

If recycling isn’t an option, the wood can be repurposed for bioenergy. And since the source material is renewable, new trees can be planted to continue the cycle.

In Summary

The lifecycle of a mass timber building is a story of innovation, responsibility, and sustainability. From a seedling in a forest to a stunning skyscraper in the city, each stage is carefully managed to reduce waste, lower emissions, and enhance human experience.

Mass timber is more than just a building material—it’s a movement toward a greener, smarter future. And with advancements in technology and design, its role in shaping the skylines of tomorrow is only just beginning.

Looking to integrate mass timber with smart BIM workflows? Let Silicon Valley guide you with expert BIM consulting and modeling services tailored for sustainable architecture.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.