The Role of 3D Mechanical Modeling in Modern Engineering Solutions

Modern engineering demands more than just ideas—it requires precision, speed, and adaptability. One of the most impactful tools fulfilling these demands is 3D mechanical modeling. This powerful technology allows engineers and product designers to visualize, simulate, and refine components and systems in a virtual environment long before physical prototypes are created.

With 3D mechanical modeling, industries benefit from optimized workflows, improved design communication, and a reduction in production risks. Let’s explore how this technology transforms the engineering process from design to deployment.

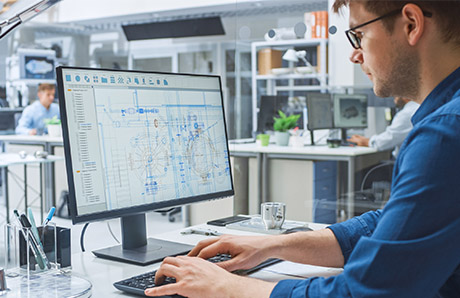

1. Advanced Visualization and Communication

3D modeling provides a lifelike representation of components, assemblies, and systems. Unlike flat 2D drawings, it allows stakeholders to rotate, zoom, and dissect every element of a design. This is especially useful in multidisciplinary teams, where engineers, designers, and clients need to collaborate on a single platform.

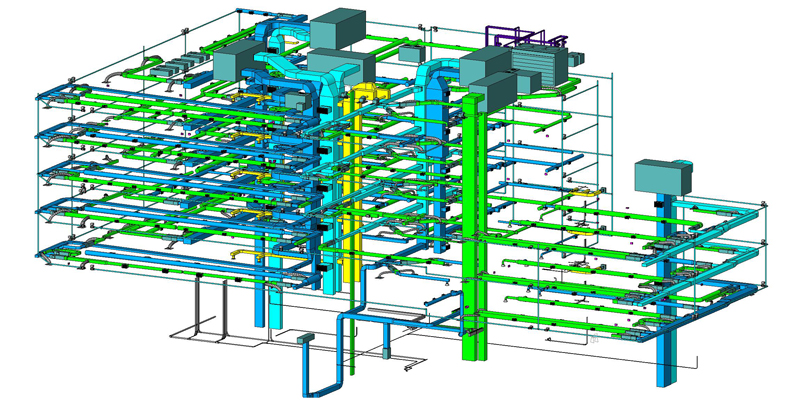

For example, in mechanical BIM services, 3D modeling enables seamless coordination between mechanical, electrical, and structural systems. Clash detection and interference analysis can be performed early, reducing costly field errors during construction or manufacturing.

2. Unmatched Accuracy and Design Precision

3D modeling ensures that every part fits perfectly before it reaches the production floor. By working with parametric and constraint-based designs in tools like SolidWorks, Autodesk Inventor, and Revit, engineers maintain full control over every feature and dimension.

This level of accuracy helps in:

- Reducing manual drafting errors

- Creating design iterations faster

- Ensuring tight tolerances in production

- Validating design intent with simulation tools

Additionally, Mechanical CAD Modeling Services help engineers standardize their documentation and conform to industry-specific drawing codes.

3. Efficient Prototyping and Faster Time-to-Market

With traditional workflows, developing prototypes is time-consuming and expensive. However, 3D modeling reduces dependency on physical prototypes in early design stages. Engineers can simulate materials, movement, and external forces digitally, saving both time and money.

Digital models can also be easily translated into 3D prints or CNC machine codes for rapid prototyping, enabling real-world testing and feedback without extended lead times.

4. Seamless Integration with Simulation and Testing

Before building a single part, engineers can run stress, thermal, and motion analysis on their models. 3D mechanical modeling tools are integrated with FEA (Finite Element Analysis) and CFD (Computational Fluid Dynamics) software, allowing real-time simulations of mechanical behavior.

This integration helps:

- Predict wear and fatigue

- Validate structural integrity

- Optimize designs for different operating conditions

- Avoid performance issues post-manufacture

This capability is particularly useful in aerospace, automotive, and heavy machinery industries where safety and reliability are non-negotiable.

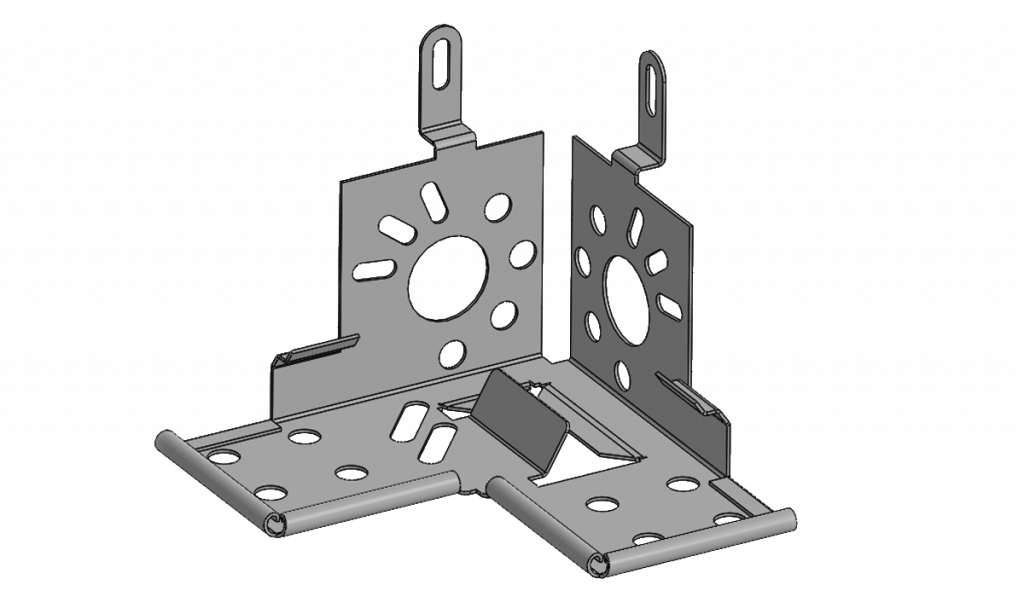

5. Enabling Customization and Complex Assemblies

3D modeling makes it easier to modify parts, create product variants, and manage complex assemblies. For example:

- A designer can quickly swap materials or change dimensions to meet client-specific needs.

- Large assemblies with hundreds of components (like HVAC systems or industrial equipment) can be structured and tested virtually.

- Configurations and BOMs (Bill of Materials) can be generated automatically.

- Mechanical Product 3D CAD Modeling Services allow the creation of reusable templates and libraries that accelerate future projects without starting from scratch.

6. Enhanced Manufacturing and Production Planning

3D mechanical models are the backbone of modern manufacturing. The CAD data can be directly imported into CAM (Computer-Aided Manufacturing) software, ensuring that CNC machines, laser cutters, or 3D printers execute precise instructions with minimal waste.

Manufacturers can also use the models for:

- Process simulation

- Assembly line planning

- Quality checks

- Digital twin implementation

This digitization leads to a more controlled, cost-efficient, and optimized manufacturing pipeline.

The shift from 2D drafting to intelligent, parametric 3D modeling has revolutionized how engineers design, validate, and manufacture products. It not only reduces time and errors but also opens doors for innovation, automation, and sustainability.

As Industries delivers comprehensive 3D Mechanical Modeling Services designed to meet the diverse needs of the engineering and manufacturing sectors. Our skilled team combines deep industry knowledge with expertise in tools like SolidWorks, Revit, Inventor, and AutoCAD to produce intelligent and production-ready models that streamline development and improve product quality. Whether it’s for BIM coordination, product prototyping, or system simulation, we’re committed to helping our clients turn ideas into reality—with precision, speed, and value.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.