The Ultimate Guide to UV LED Chip Manufacturers and UV LED Modules

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today’s rapidly evolving technology landscape, UV LED chips and UV LED modules are playing an increasingly critical role in industries ranging from healthcare to industrial manufacturing. As the demand for ultraviolet (UV) light applications grows, choosing the right UV LED chip manufacturer becomes essential for businesses aiming to maximize efficiency, performance, and longevity in their products. This comprehensive guide will delve into the key aspects of UV LED technology and provide insights into selecting the best UV LED chip manufacturers and modules.

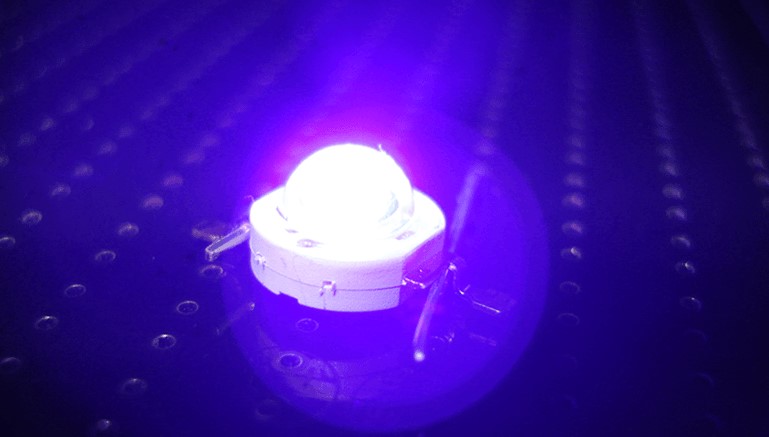

What Are UV LED Chips?

UV LED chips are small, semiconductor-based devices that emit ultraviolet light when an electric current passes through them. Unlike traditional UV lamps, UV LEDs do not contain hazardous materials like mercury, making them a safer and more environmentally friendly option.

UV LED chips can be categorized into three main types based on the wavelength of light they emit:

- UV-A LEDs (315-400 nm): Used in applications like curing, counterfeit detection, and forensic investigations.

- UV-B LEDs (280-315 nm): Primarily used in medical treatments and skin therapies.

- UV-C LEDs (100-280 nm): Known for their powerful germicidal properties, UV-C LEDs are widely used in sterilization and disinfection.

The Role of UV LED Modules in Industrial Applications

A UV LED module consists of one or more UV LED chips integrated into a housing with additional electronic components like drivers and heat sinks. Modules are used to ensure efficient power delivery, proper thermal management, and ease of integration into larger systems.

Industries such as printing, medical sterilization, water purification, and air disinfection depend on UV LED modules for their day-to-day operations. These modules are particularly valued for their energy efficiency, long lifespan, and low maintenance requirements compared to traditional UV lighting solutions.

Top Benefits of UV LED Technology

1. Energy Efficiency

One of the greatest advantages of UV LED chips is their low power consumption compared to traditional UV lamps. UV LEDs offer a much more efficient solution, using less energy while delivering the same or better output. This makes them ideal for businesses aiming to reduce their energy bills and minimize their environmental footprint.

2. Long Lifespan

UV LED modules have an extended operational life, often exceeding 50,000 hours. This is significantly longer than traditional mercury-based UV lamps, which typically last between 1,000 and 10,000 hours. The long lifespan of UV LED chips translates into fewer replacements and lower overall maintenance costs.

3. Environmentally Friendly

Unlike mercury vapor lamps, UV LEDs are free from toxic chemicals, making them a green technology. UV LEDs are also 100% recyclable, further reducing their impact on the environment.

4. Compact Design

UV LED modules offer a compact design that allows for easy integration into various devices and systems. Their small size and efficient performance make them ideal for applications where space is a concern.

5. Instant-On Capabilities

UV LEDs do not require a warm-up time like traditional UV lamps. They offer instant-on capabilities, allowing for immediate use without delays. This feature is particularly beneficial in industrial processes that require quick and precise UV light activation, such as UV curing and photolithography.

Key Applications of UV LED Chips and Modules

1. Water and Air Sterilization

The disinfection capabilities of UV-C LED chips have become essential in water and air purification systems. These UV LEDs are capable of eliminating bacteria, viruses, and harmful pathogens without the need for chemical additives. This makes them perfect for water treatment plants, HVAC systems, and portable sterilization devices used in healthcare.

2. UV Curing

UV-A and UV-B LEDs are critical in UV curing applications. This process is widely used in the printing, coating, and adhesive industries, where UV light is used to cure inks, varnishes, and other materials. UV curing is faster, more reliable, and environmentally friendly compared to traditional heat-based curing methods.

3. Medical Sterilization

The healthcare industry relies on UV-C LED modules for sterilizing medical instruments, surfaces, and even air in medical facilities. UV-C technology is highly effective in reducing the risk of infections, making it a valuable asset for hospitals and clinics.

4. Forensics and Counterfeit Detection

In forensic science, UV-A LED chips are employed to detect biological evidence like blood, saliva, and other fluids. They are also used in counterfeit detection to authenticate currencies, documents, and valuable items by revealing hidden security features.

5. Security and Fraud Prevention

UV LEDs are frequently used in security applications. By embedding UV-sensitive inks into products and documents, organizations can prevent fraud and ensure authenticity. The inks are invisible to the naked eye but can be revealed using a UV light, making this an effective tool for safeguarding sensitive materials.

Choosing the Best UV LED Chip Manufacturers

When selecting a UV LED chip manufacturer, it is important to consider several key factors that will ensure you receive the highest quality products that meet your specific needs.

1. Quality and Reliability

High-quality UV LED chips are designed for durability and reliability, which are critical in applications like medical sterilization and water purification. Look for manufacturers that prioritize rigorous testing and quality control processes to guarantee that their chips meet global standards.

2. Customization Options

Top UV LED chip manufacturers often offer customized solutions that cater to the unique requirements of your industry. Whether you need specific wavelengths, power outputs, or chip configurations, choosing a manufacturer that provides flexible options is vital.

3. R&D Capabilities

Manufacturers with a strong focus on research and development are better equipped to deliver cutting-edge UV LED technology. R&D not only helps improve the efficiency of UV LED chips but also enables manufacturers to develop innovative solutions that keep pace with market demands.

4. Certifications and Compliance

Ensure that the manufacturer you choose complies with international certifications such as ISO 9001, RoHS, and CE standards. These certifications are indicative of the manufacturer’s commitment to producing safe, environmentally friendly, and high-quality UV LED chips.

5. Competitive Pricing

While quality is important, pricing also plays a major role in your decision. Choose a manufacturer that offers competitive pricing without compromising on the quality of the UV LED module. Bulk orders or long-term partnerships can often help secure better rates.

Top UV LED Chip Manufacturers to Consider

Several UV LED chip manufacturers have established themselves as leaders in the market due to their commitment to quality, innovation, and customer support. Companies like Tianhui LED, Nichia, and Seoul Viosys are known for delivering high-performance UV LED chips and modules that are used in industries worldwide.

These manufacturers offer a wide range of UV LED products that cater to applications such as sterilization, curing, security, and more. By investing in products from reputable manufacturers, businesses can ensure long-term performance and reliability.

Conclusion

The demand for UV LED chips and UV LED modules continues to grow as industries seek more efficient, eco-friendly, and versatile solutions. Whether for water purification, UV curing, or medical sterilization, selecting the right UV LED chip manufacturer is crucial for achieving the best performance.

By considering factors such as quality, customization, R&D, and pricing, businesses can partner with leading manufacturers to secure reliable and long-lasting UV LED solutions. As the technology advances, UV LEDs will play an even greater role in improving efficiency and sustainability across various industries.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.