Tips for Maximizing Efficiency with Pin Vises on CNC

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

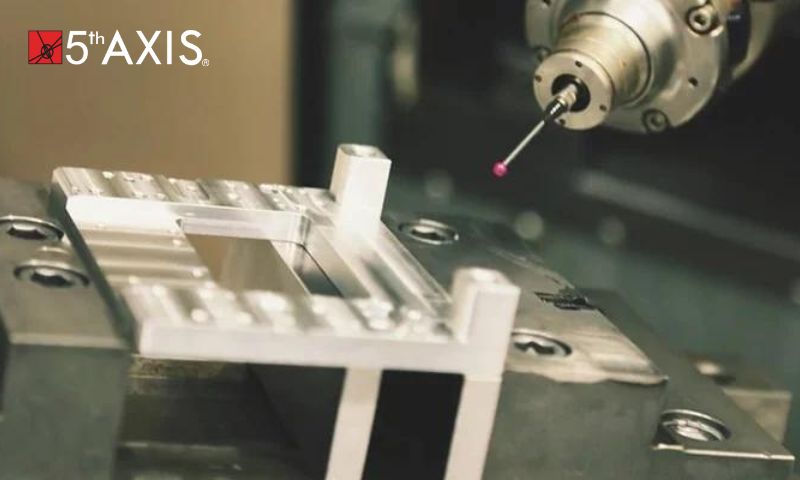

In the world of CNC machining efficiency isn't just about being fast—it's about making every second and every move count. Have you ever considered how much the jaws on your machine impact your work? Pin Vise Machinable Jaws provided by 5th Axis are designed to make your CNC operations better and faster. Let's see how these advanced tools can take your production efficiency to the next level.

Understanding the Role of Pin Vises

Tools like the widely used Machinable Jaws Pin Vise-PMV3XS or the DV75150X-MJ-A-Double Station Machinable Jaws (Aluminum) are made to do more than just hold things tightly. They help to increase the precision and speed of CNC machines making them essential for high-quality manufacturing. But what really sets Pin Vises apart from other machining tools?

Pin Vises: Boosting CNC Machine Efficiency

1. Precision Alignment

Maximizing efficiency in CNC machining starts with precisely aligning the workpiece. Pin Vises ensure that each piece is held securely and exactly in the right spot. This reduces the need for time-consuming adjustments and fixes. Have you ever considered how costly even a tiny misalignment can be?

2. Versatility Across Materials

Different materials behave differently when machined. Pin Vises like the DV75150X-MJ-S-Double Station Machinable Jaws (Steel) and V75100X-5CDV-Center Hard Jaw are specially made to handle various materials from aluminum to steel. They ensure optimal handling and reduce waste. How many other jaws can adapt so well to different materials?

3. Quick Setup Changes

Changing setups is often a slow part of CNC machining. Pin Vises are built for quick and easy changes greatly reducing downtime. What if you could cut setup times in half? Think about how that could speed up your production.

Tips for Utilizing Pin Vises to Their Full Potential

Regular Maintenance: Keep your Pin Vises in good shape with regular checks and care. Jaws that are well-maintained work the best.

Proper Installation: Make sure your Pin Vises are put in correctly. A jaw that's not installed right can lead to inefficiency and damage.

Match the Jaw to the Job: Always use the Pin Vise Jaw that's meant for the material and job type you're doing. This improves efficiency and helps your tools and workpieces last longer.

Real-World Impact of Pin Vises: A Case Study

Look at a high-volume automotive parts maker who switched to Pin Vises. By using the DV75150X-3R-Hard Jaw Set which is perfect for their needs they cut down machine setup time by 40% and reduced scrap by 30%. These improvements made their production faster and cheaper.

Why Choose Pin Vises from 5th Axis?

When you pick Pin Vises from 5th Axis you're choosing a partner who is committed to making your CNC machining better. Our jaws are made to be precise and efficient and they're designed for modern manufacturing demands. With a variety of models like the Machinable Jaws Pin Vise-PMV3XS and the strong DV75150X-MJ-S-Double Station Machinable Jaws (Steel) we offer solutions that improve your CNC operations at every level.

Expanding Your Capabilities with Pin Vises

As you continue to use Pin Vises you'll start to see their impact not just on individual projects but across your entire machining process. These jaws allow you to take on more complex and varied projects with confidence. Each new project becomes a chance to push the limits of what your CNC machine can achieve. This capability to handle diverse and challenging tasks can significantly widen your market opportunities.

Enhancing Workplace Safety with Pin Vises

Safety in the workplace is paramount especially when dealing with high-speed machinery like CNC machines. Pin Vises contribute to a safer work environment by providing a secure hold on workpieces reducing the chance of accidents caused by slippage. When tools perform reliably operators are less likely to face unpredictable movements leading to a safer and more controlled operation. Isn’t ensuring the well-being of your team while maintaining productivity a win-win scenario?

Sustainability and Cost-Efficiency with Pin Vises

Using Pin Vises also promotes sustainability in your machining operations. By reducing material waste and improving process efficiency you contribute to more environmentally friendly production practices. Less scrap means less waste and efficient use of materials helps conserve resources. Additionally the durability of Pin Vises means you won’t need to replace them as often saving money and reducing environmental impact over time.

Keeping Up with Industry Standards Using Pin Vises

As manufacturing technology evolves, staying current with industry standards becomes essential. Pin Vises help you meet these standards by enabling precision and consistency in your work. With high-quality reliable tools like those from 5th Axis you ensure that your outputs not only meet but often exceed industry expectations. Staying ahead of the curve with the latest tooling innovations can set your operations apart from competitors.

Pin Vises: A Tool for Future Growth

As you look to the future of your CNC machining operations, consider how integrating Pin Vises into your workflow can contribute to long-term growth and success. These tools are not just about improving current processes—they are about preparing your business for future challenges and opportunities. With the right tools your machine’s potential is limitless and so is your business’s growth.

Conclusion: Making the Switch to Pin Vises

Now that you understand the full scope of benefits that Pin Vises offer from enhancing efficiency and safety to ensuring sustainability and compliance with industry standards the decision to integrate these tools into your CNC operations is clear. Pin Vises from 5th Axis are more than just an investment in tooling; they are an investment in the future of your manufacturing capabilities.

Are you ready to embrace these benefits and see real improvements in your production quality and efficiency? Visit 5th Axis today to explore our range of Pin Vise Machinable Jaws and start on the path to a more productive and successful machining operation. Let Pin Vises be the key to unlocking your CNC machine’s full potential. Why wait to achieve excellence? Make the switch now and propel your projects to new heights.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.