Tooling Board Market Size, Demand, Industry Trends and Analysis Report 2024-2032

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

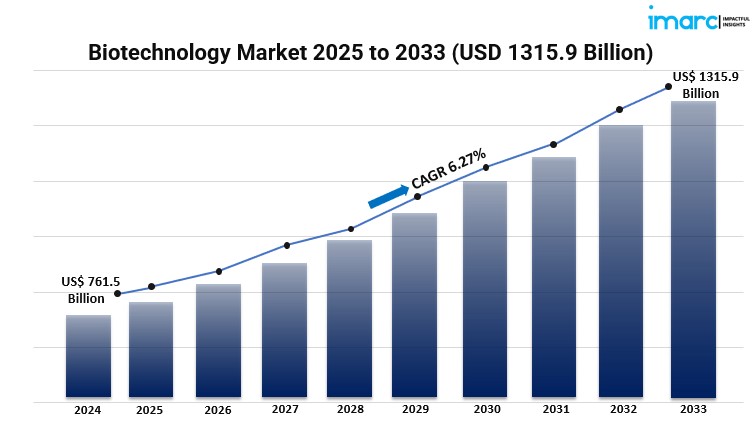

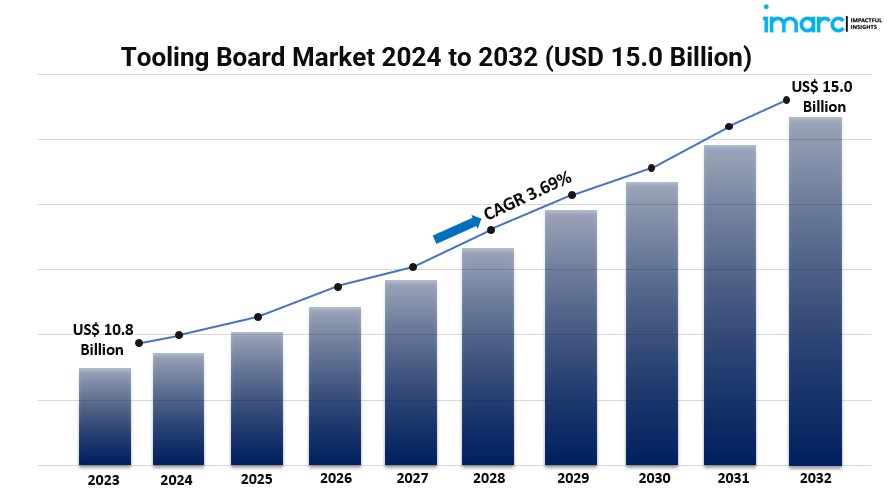

The latest report by IMARC Group, titled “Tooling Board Market Report by Material (Polyurethane, Epoxy Resins, and Others), Application (Aerospace and Defense, Automotive, Marine, Wind Energy, and Others), and Region 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on the market. The global tooling board market size reached USD 10.8 Billion in 2023. Looking forward, IMARC Group expects the market to reach USD 15.0 Billion by 2032, exhibiting a growth rate (CAGR) of 3.69% during 2024-2032.

Factors Driving the Growth of the Tooling Board Industry:

- Unmatched Versatility and Customization:

The tooling board industry's expansion is significantly fueled by its exceptional versatility and customization capabilities. These boards are manufactured in a wide array of materials, each offering unique properties tailored to specific applications. From the density and hardness of the material to its machinability, manufacturers can select the optimal tooling board to meet their precise requirements. This adaptability proves invaluable across numerous sectors. In automotive design, for example, tooling boards enable the creation of intricate and complex prototypes, while in aerospace, their precision facilitates the production of highly accurate molds for critical components. Beyond material selection, the ease with which these boards can be manipulated is a key advantage. Standard machining processes such as milling, routing, and drilling allow for the creation of intricate geometries and fine details with remarkable accuracy. This flexibility extends beyond prototyping; it streamlines production workflows, accelerates design iterations, and significantly reduces lead times. This combination of material choice and machining ease positions tooling boards as the preferred solution for rapid prototyping and iterative design, ultimately boosting efficiency and reducing time-to-market.

- Superior Durability and Dimensional Stability:

The remarkable durability and dimensional stability of tooling boards are additional key factors driving their widespread adoption. These boards are engineered to withstand the demanding conditions of various manufacturing processes, including molding, casting, and extensive machining, without compromising performance or dimensional accuracy. This resilience contrasts sharply with traditional materials like wood or plaster, which are prone to warping, shrinking, or expanding in response to temperature fluctuations, humidity changes, or mechanical stress. Tooling boards, however, maintain exceptional dimensional stability, ensuring consistent results and minimizing material waste. This consistency is crucial, whether the application involves the creation of a single prototype or high-volume production runs. Manufacturers can confidently rely on the dependable performance and repeatable results offered by tooling boards. The extended lifespan of tooling boards is further enhanced by their inherent resistance to chemical damage, solvent degradation, and moisture absorption. This makes them exceptionally well-suited for long-term use in even the most demanding industrial environments, reducing the need for frequent replacements and associated costs.

- Enhanced Cost-Effectiveness and Sustainable Practices:

The rising popularity of tooling boards is inextricably linked to their cost-effectiveness and alignment with sustainable manufacturing practices. Compared to traditional materials such as metals or composites, tooling boards provide a significantly more affordable alternative without compromising on quality or performance. The lower material cost, combined with the efficiency gained from reduced machining times and minimal post-processing, translates to substantial savings throughout the production process. The lightweight nature of tooling boards further contributes to cost reduction, as lower shipping and handling costs are incurred compared to heavier alternatives. The machinability of these boards allows for efficient material utilization, minimizing waste and maximizing resource allocation. This responsible use of resources directly aligns with contemporary sustainability initiatives aimed at reducing environmental impact and promoting eco-conscious manufacturing. By reducing material waste and lowering overall production costs, tooling boards offer a compelling solution that enhances profitability while simultaneously contributing to a more sustainable manufacturing landscape.

For an in-depth analysis, you can request a sample copy of the report: https://www.imarcgroup.com/tooling-board-market/requestsample

Competitive Landscape:

The competitive landscape of the market has been studied in the report with detailed profiles of the key players operating in the market.

- Alchemie Ltd.

- Alro Steel Corporation

- Base Materials Ltd

- Coastal Enterprises

- Curbell Plastics Inc.

- General Plastic Manufacturing Co.

- Goldenwest Manufacturing Inc.

- Huntsman Corporation

- OBO-Werke GmbH

- RAMPF Holding GmbH & Co.KG

- Sika AG

- Trelleborg AG

Tooling Board Market Report Segmentation:

By Material:

- Polyurethane

- Epoxy Resins

- Others

Polyurethane dominates the market due to its versatility, durability, and cost-effectiveness.

By Application:

- Aerospace and Defense

- Automotive

- Marine

- Wind Energy

- Others

The aerospace and defense industry is a major driver of the tooling board market, owing to its stringent quality standards and the need for advanced materials and technologies.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Europe holds a significant share of the market, driven by its strong industrial base, focus on innovation, and favorable regulatory environment.

Global Tooling Board Market Trends:

The global tooling board market is driven by several key trends. One of the primary factors is the increasing demand for faster product development cycles and shorter time-to-market. Tooling boards offer a versatile and efficient solution for prototyping, tooling, and production. Their ease of machining and handling, coupled with their durability and stability, allows for rapid prototyping and iterative design processes. Additionally, the growing emphasis on sustainability and environmental responsibility is driving the adoption of tooling boards. These materials often require less energy to produce and process compared to traditional materials, reducing the overall environmental impact. Furthermore, the ability to recycle and reuse tooling boards contributes to a more sustainable manufacturing process. The increasing complexity of product designs, particularly in industries such as automotive, aerospace, and electronics, is also driving the demand for advanced tooling materials. Tooling boards can be customized to meet the specific needs of these industries, enabling the production of intricate and high-precision components.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=3419&flag=C

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provides a comprehensive suite of market entry and expansion services. IMARC offerings include a thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.