Top Challenges in BIM Fabrication—and How to Overcome Them

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

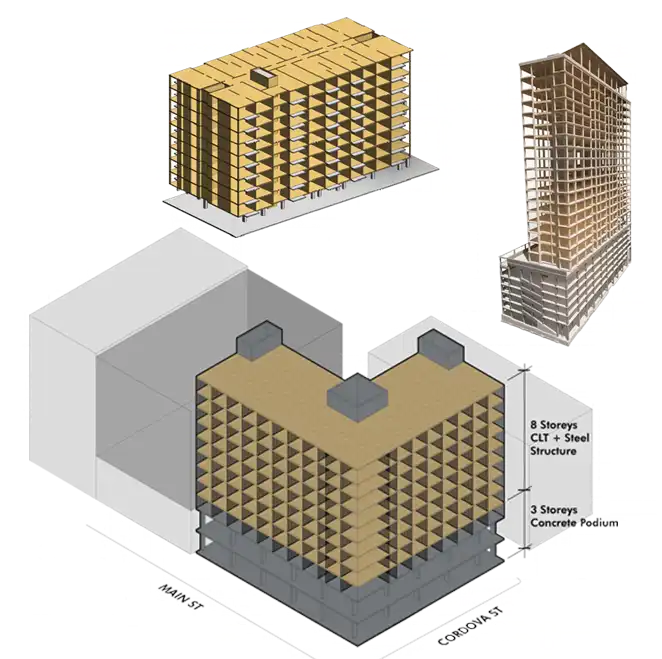

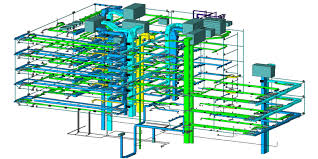

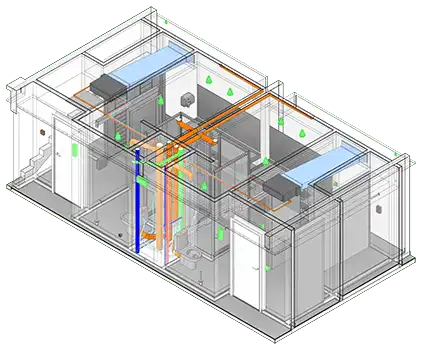

BIM Fabrication Services have transformed how construction professionals approach manufacturing, assembly, and installation of building components. From MEP systems to steel structures, BIM-based fabrication brings accuracy, efficiency, and coordination to the forefront. However, like any technology-driven process, it’s not without its challenges.

Here’s a closer look at some of the most common hurdles in BIM fabrication—and practical ways to overcome them.

1. Data Inconsistencies Between Design and Fabrication Models

One of the major pain points in BIM fabrication is the inconsistency between design intent and fabrication-level models. Design models often focus on conceptual and visual representation, while fabrication models require high levels of detail and precision for real-world manufacturing.

Solution:

Clear communication between design and fabrication teams is essential. Implementing LOD (Level of Development) standards ensures the model transitions smoothly from design to fabrication. Using interoperable BIM software like Revit, AutoCAD, or Tekla integrated with fabrication tools minimizes data loss and errors.

2. Limited Fabrication Knowledge Among Design Teams

Architects and engineers may create beautiful 3D models that look good on screen but aren't practically feasible for fabrication. This knowledge gap can lead to delays, costly rework, and RFIs during construction.

Solution:

Involve fabricators early in the project lifecycle. Adopting Integrated Project Delivery (IPD) or collaborative BIM workflows helps bring all stakeholders—including manufacturers—on board from day one. Also, cross-training design professionals in fabrication requirements improves model constructability.

3. Software Compatibility and File Format Issues

Even with the rise of open BIM standards, not all software platforms speak the same language. Moving models between different tools (like from Revit to a fabrication platform or CNC machine) can cause data loss, geometry distortion, or missing components.

Solution:

Adopt industry-standard file formats such as IFC, DWG, and STEP where possible. Tools like Autodesk Revit, Advance Steel, or Trimble’s Tekla offer better compatibility when working within a unified ecosystem. Using middleware tools or plugins for format conversion can also bridge the gap.

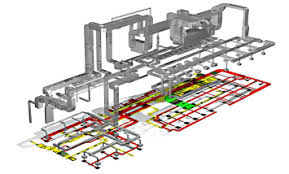

4. Clash Detection and Coordination Errors

Even a minor clash between HVAC ductwork and structural steel can lead to costly delays during installation. If fabrication starts before resolving these conflicts, rework becomes inevitable.

Solution:

Perform early and frequent clash detection using tools like Navisworks, BIM 360, or Solibri. Set up coordination meetings and BIM review sessions at every major project milestone to ensure all disciplines are aligned. A well-managed BIM coordination process drastically reduces on-site issues.

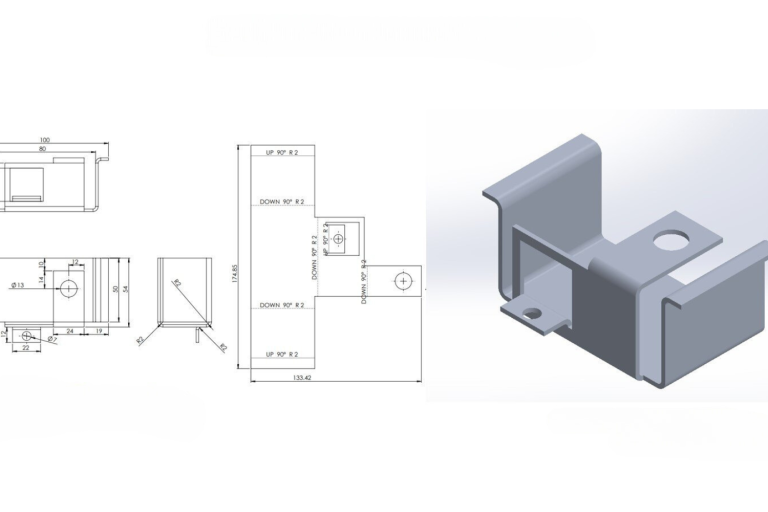

5. Fabrication Model Accuracy and LOD Mismatch

Sometimes, models are sent to fabrication without the required detail level, leading to issues during CNC processing or component assembly. A mismatch in the expected Level of Development (LOD) results in confusion about what is ready for fabrication and what is not.

Solution:

Use clearly defined BIM Execution Plans (BEPs) and ensure that all teams follow agreed-upon LOD definitions (e.g., LOD 300 for coordination, LOD 400 for fabrication). Establish quality control checks before approving models for shop drawings or digital fabrication.

6. Managing Change Orders in Real-Time

Changes during construction are inevitable—but managing them in a fabrication workflow can be challenging. Late-stage design updates might not reflect in already-fabricated components, causing misalignments.

Solution:

Utilize cloud-based BIM platforms (like Autodesk BIM 360 or Trimble Connect) that allow real-time model updates and version control. This ensures that all stakeholders are working with the most recent model. A robust change management protocol helps track and document modifications before fabrication begins.

7. Lack of Standardization in Fabrication Processes

Different fabricators have different preferences, workflows, and standards. This inconsistency can result in miscommunication, model misinterpretation, and delays in production.

Solution:

Create and follow company-specific BIM standards and templates for fabrication. Use BIM content libraries that include manufacturer-specific elements and parametric families. Consistent documentation and process alignment reduce guesswork and enhance model usability.

8. Skilled Workforce Shortage

As BIM fabrication grows, the demand for professionals who can handle both modeling and fabrication requirements is increasing. Unfortunately, there's a shortage of skilled BIM modelers with fabrication knowledge.

Solution:

Invest in ongoing training programs for your BIM and fabrication teams. Upskill existing staff with courses in fabrication modeling, parametric modeling, and detailing. Collaborate with technical institutions to promote BIM education tailored for fabrication workflows.

Final Thoughts

BIM Fabrication Services are revolutionizing how buildings are planned, produced, and assembled. But embracing this technology also means facing and resolving the challenges that come with it. By improving coordination, adopting the right tools, setting clear standards, and investing in skilled talent, you can fully unlock the power of BIM fabrication.

Looking to streamline your BIM fabrication workflow? Let our experts at Silicon Valley Infomedia help you with tailored BIM solutions—from 3D modeling to fabrication-ready detailing. Get in touch today!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.