Top Qualities to Look for in a Reliable Hydraulic Gear Pump Manufacturer

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

When industries rely on heavy-duty machinery, one of the most critical components they need is a hydraulic gear pump. Whether you're in construction, agriculture, mining, or manufacturing, choosing the right hydraulic gear pump manufacturer is essential for the smooth operation of your equipment. But with so many options available globally, how can you make the best choice?

In this article, we will guide you through what makes a manufacturer trustworthy, what to consider before buying, and why quality matters. If you're searching for a dependable supplier for hydraulic gear pumps, read on.

What Is a Hydraulic Gear Pump?

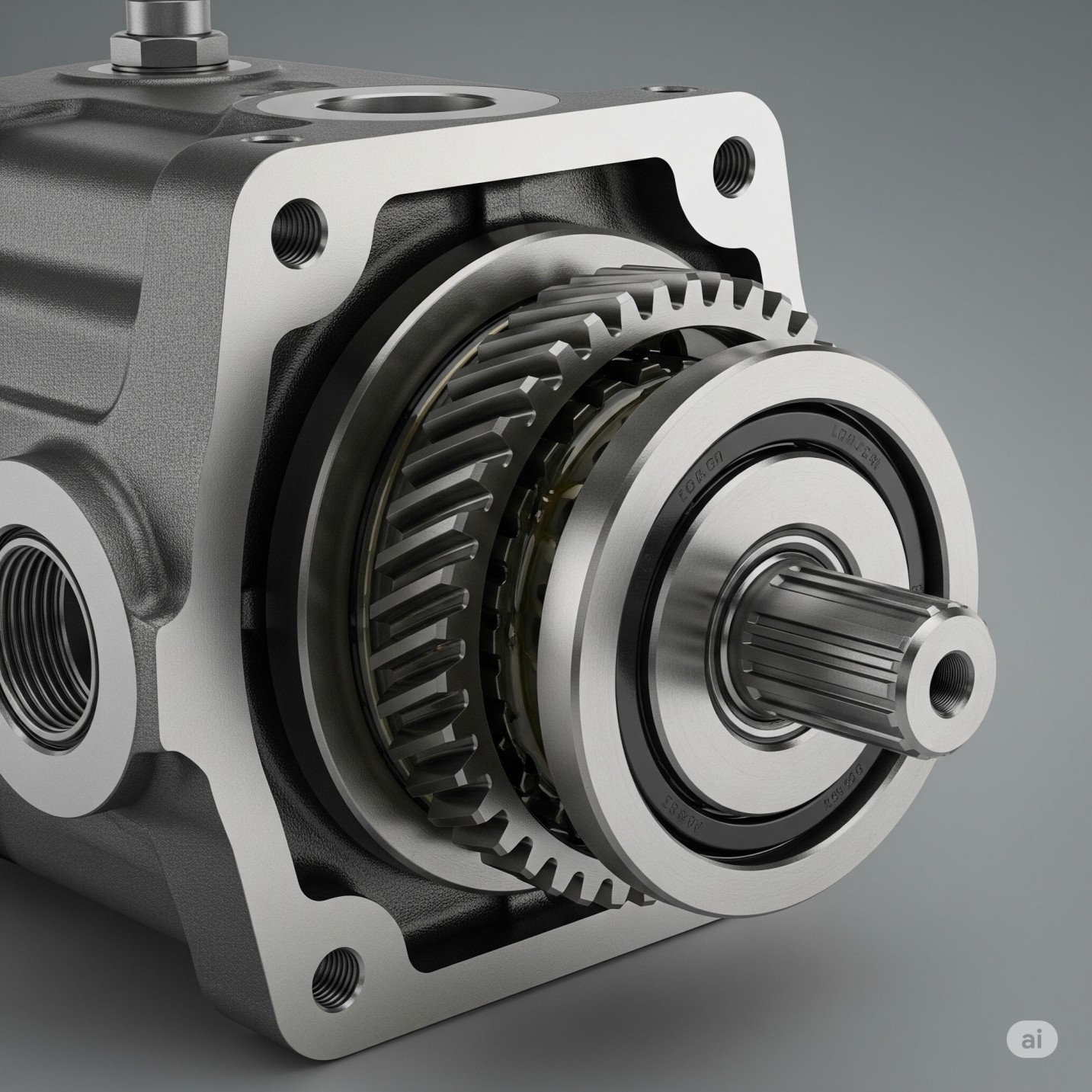

One kind of positive displacement pump is a hydraulic gear pump. It is frequently used in hydraulic systems to transport fluids, such as oil, by means of interlocking gears. These pumps are renowned for their efficiency, portability, and longevity. They are frequently found in devices like industrial presses, tractors, excavators, and forklifts.

Why Choosing the Right Manufacturer Matters

Many hydraulic systems are powered by hydraulic gear pumps. A low-quality pump can lead to frequent breakdowns, high maintenance costs, and potential safety risks. A reputable manufacturer ensures the pump meets international standards, lasts longer, and performs under demanding conditions.

Here’s what you should expect from a trusted hydraulic gear pump manufacturer:

- Quality assurance

- Reliable materials

- Advanced engineering

- Consistent supply

- Good after-sales support

Key Factors to Consider While Selecting a Hydraulic Gear Pump Manufacturer

1. Experience and Industry Reputation

Look for manufacturers with years of experience in the hydraulic industry. Companies that have been around for decades often have a deep understanding of customer needs and produce high-performance pumps. Online reviews, certifications, and testimonials are great indicators of a company's credibility.

2. Product Range and Customization

A good hydraulic gear pump manufacturer offers a wide variety of models that suit different flow rates, pressures, and configurations. They should also provide custom-built pumps for specific industrial requirements.

3. Material and Build Quality

Cast iron, aluminum, and steel are among the premium materials used to make the best gear pumps. The internal gears should be heat-treated for added strength. Ask the manufacturer about the materials used in both the housing and the gears.

4. Global Shipping and Support

If you’re sourcing from an international manufacturer, ensure they can ship worldwide and offer technical support across time zones. A manufacturer with global reach understands export standards and can ensure smooth delivery without delays.

5. Certifications and Compliance

Always choose a manufacturer that complies with international quality standards such as ISO 9001, CE, or RoHS. These certifications guarantee that the manufacturer follows best practices in manufacturing and quality control.

Benefits of Buying from a Trusted Hydraulic Gear Pump Manufacturer

Longer Lifespan

- Top-grade gear pumps are designed to withstand extreme working conditions, offering more hours of service.

Efficient Performance

- A well-designed gear pump minimizes energy consumption and improves overall system efficiency.

Low Maintenance

- Reliable manufacturers use parts that are resistant to wear and corrosion, reducing the need for frequent repairs.

Better Warranty Terms

- Reputed manufacturers usually offer solid warranty policies and quick replacement options.

Technical Support

- You get access to installation guides, user manuals, and direct technical assistance in case of issues.

Emerging Trends in Hydraulic Gear Pump Manufacturing

Manufacturers today are adopting newer technologies to stay ahead in the competitive market:

- Eco-friendly designs that reduce environmental impact.

- Smart pumps with sensor integration for monitoring performance.

- Energy-efficient models to cut down on operational costs.

- 3D printing enabling quicker production cycles and quick prototyping.

- Staying updated with these trends helps industries choose modern and future-proof solutions.

Questions to Ask Your Hydraulic Gear Pump Supplier

- Which materials are utilized in the pump's construction?

- Are the pumps tested for pressure and leakage before shipping?

- Do you provide custom gear pump solutions?

- How long does it typically take for orders placed from overseas to be delivered?

- What kind of after-sales service do you offer?

Asking the right questions will ensure you're not just buying a product but forming a long-term partnership with a reliable supplier.

Conclusion

A hydraulic gear pump manufacturer plays a crucial role in the performance and longevity of your hydraulic systems. From material quality to technical expertise, every factor contributes to a better end product. Don’t compromise when it comes to sourcing hydraulic parts—choose a partner who prioritizes innovation, quality, and customer satisfaction.

Whether you're upgrading existing equipment or setting up a new project, investing in a trusted manufacturer will save you time, money, and hassle in the long run.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.