Understanding LVDT Transducers

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Understanding LVDT Transducers: Versatile Sensors for Precision Measurement

In the realm of engineering and industrial applications, the quest for precise measurement and control drives the development of various sensors and transducers. Among these, the LVDT (Linear Variable Differential Transformer) stands out as a robust and highly accurate device, widely used across industries ranging from aerospace to manufacturing. This article explores the workings, applications, advantages, and future prospects of LVDT transducers.

What is an LVDT?

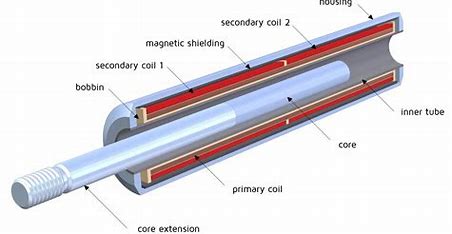

An LVDT is a type of electromechanical sensor designed to convert mechanical motion into an electrical signal. It operates on the principle of electromagnetic induction and consists of a primary winding (excitation coil) and two secondary windings (output coils). The core, typically made of ferromagnetic material, moves linearly within the coil assembly in response to the measured displacement. This movement induces voltages in the secondary windings, which are then used to determine the position of the core.

Working Principle

The working principle of an LVDT revolves around Faraday's law of electromagnetic induction. When an AC voltage is applied to the primary winding, it generates a magnetic field that induces voltages in the secondary windings. The voltage induced in each secondary winding varies with the position of the core inside the LVDT body. By measuring the differential output between the two secondary windings, the displacement of the core (and hence the measured object) can be accurately determined.

Applications

LVDTs find applications in a wide range of industries where precise linear position measurements are critical. Some notable applications include:

- Aerospace: Used in flight control systems, hydraulic actuators, and engine thrust measurement.

- Automotive: Position sensing in suspension systems, gearbox controls, and braking mechanisms.

- Manufacturing: Precision gauging and alignment in machining processes.

- Medical: Position feedback in MRI machines, robotic surgery, and patient positioning systems.

- Energy: Monitoring of turbine blade positions in power plants and valve position feedback in pipelines.

The ability of LVDTs to operate in harsh environments, resist electromagnetic interference, and provide reliable performance over extended periods makes them indispensable in these demanding applications.

Advantages of LVDT Transducers

1. High Accuracy: LVDTs can achieve high resolution and repeatability, making them suitable for applications requiring precise measurements.

2.Longevity and Reliability: With no physical contact between the core and the coil assembly, LVDTs exhibit minimal wear and can operate for millions of cycles without degradation.

3. Versatility: LVDTs can measure a wide range of displacements—from fractions of a millimeter to several inches—making them versatile across various industrial settings.

4. Robustness: Built to withstand harsh environmental conditions including temperature extremes, vibration, and shock, LVDTs maintain accuracy and reliability in challenging environments.

Future Trends

As technology advances, LVDTs continue to evolve with improvements in materials, manufacturing techniques, and signal processing capabilities. Future trends include:

- Miniaturization: Smaller LVDTs for applications in compact devices and portable equipment.

- Integration with IoT: LVDTs equipped with digital interfaces for seamless integration into smart systems.

- Enhanced Signal Processing: Advanced signal processing techniques to improve accuracy and reliability in noisy environments.

Conclusion

In conclusion, LVDT transducers represent a pinnacle of precision measurement technology. Their ability to provide accurate and reliable position feedback across a wide range of applications has cemented their place in modern engineering. As industries continue to demand higher levels of accuracy and reliability, LVDTs will undoubtedly play a crucial role in shaping the future of automation, robotics, and industrial control systems. With ongoing innovations, LVDTs are poised to remain at the forefront of sensor technology, enabling safer, more efficient, and more precise industrial processes worldwide.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.