Understanding Synchronous Timing Belts: The Power Behind Precision

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Have you ever contemplated how complicated machines can circulate with such wonderful precision?

From the engine of your car to the ideal moves of a robot arm, the timing synchronous belt has a tendency to be disregarded, even as one explores the history of something. Let's take a better look at the vital factors to see why they're so vital.

What Are Timing Synchronous Belts?

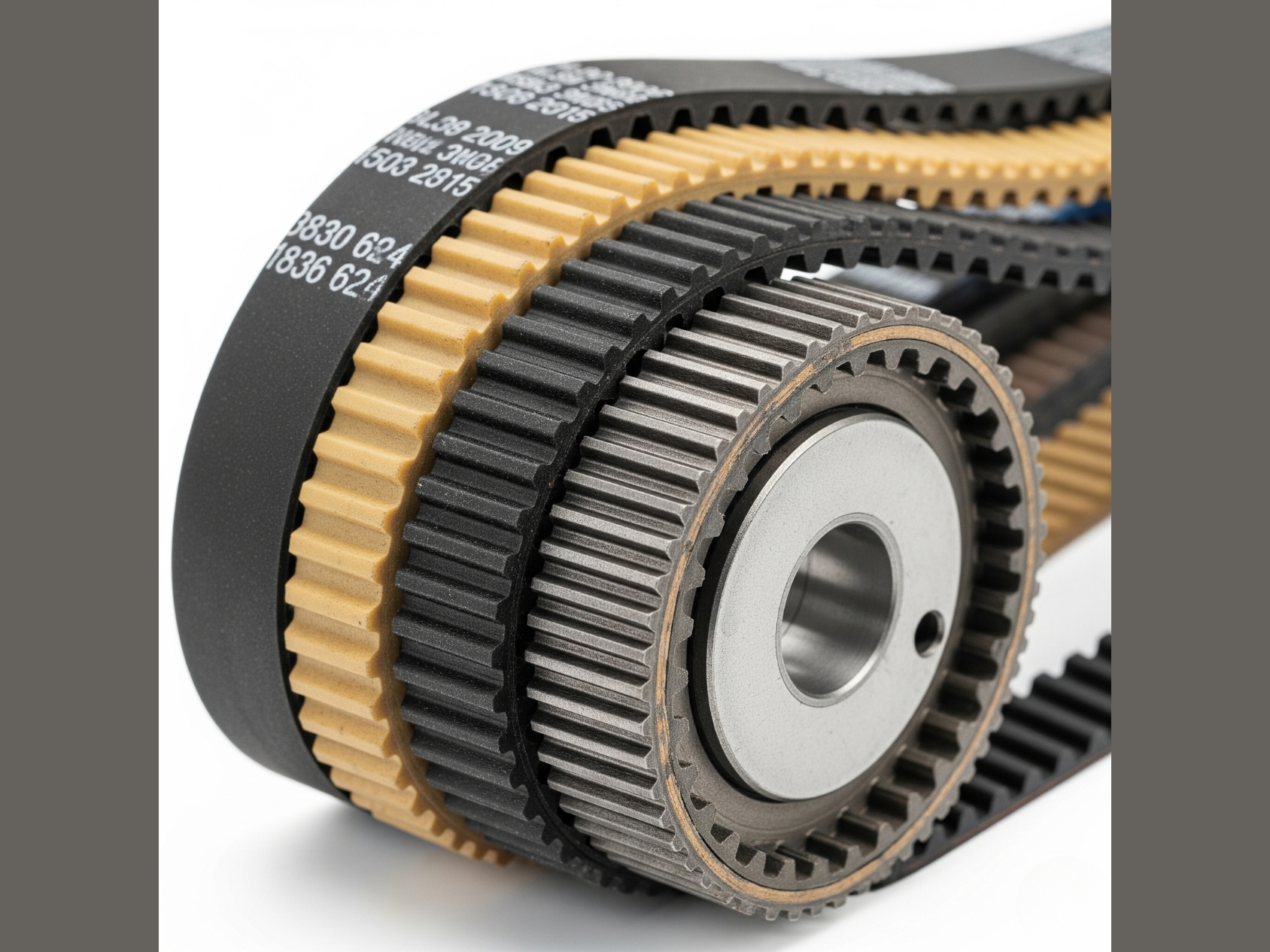

Imagine an everyday belt, but with a special twist. Timing synchronous belts are not clean; they've got teeth all along their internal surface. These enameled parts are designed to flawlessly mesh with corresponding grooves on toothed wheels, known as pulleys or sprockets. Think of it like a bicycle chain and its gears; however, in preference to metallic links, you have a bendy belt.

Those toothed belts make a nice connection, in contrast to normal belts that rely on friction and will slip. In this way, the belt ensures that the other pulley spins at the exact right speed and in best step after the primary pulley has grew to become. No slippage ever happens!

What Are They Used For?

Correctly synchronizing the motion of several parts of a device is the primary function of a timed synchronous belt. This type of belt may be found at work if precise timing is essential.

The engine of your car is the most typical example. The crankshaft is connected to the camshaft by a timing belt, sometimes referred to as a "cambelt". Because the pistons travel up and down, this ensures that the engine operates smoothly and that the valves open and close precisely at the right moment.

Beyond vehicles, you'll locate them in a huge range of machines, including:

Industrial Equipment: From conveyor structures that need to move objects at a genuine tempo to packaging machines that require unique product placement.

Robotics: For the correct and repeatable actions of robot fingers.

Printers and Scanners: Ensuring the print head or scanner moves with the best precision.

Washing Machines: In some fashions, they control the drum's rotation.

Sizes of Timing Belts

Timing belts are available in a huge range of sizes to house numerous uses. No one stylish length exists. Rather, they vary with the aid of a ramification of things:

- Length: This can be placed by way of circling the belt.

- Width: How wide the belt is.

- Tooth Profile: The tooth's form consists of rounder, trapezoidal profiles like HTD or STD. Different profiles have specific functions and strengths.

- Pitch: The separation between successive teeth.

To ensure the belt can provide the essential strength and match the pulleys effectively, these specifications are crucial.

Benefits of Timing Belts

Timing belts provide various advantages that lead them to a popular preference for specific electricity transmission:

- Pinpoint Accuracy: No slip way, best synchronization, which is crucial for a multitude of machines.

- High Efficiency: Because there's no friction-based slip, little or no strength is lost, making them exceedingly efficient.

- Quiet Operation: Compared to noisy chains or gears, timing belts run an incredible deal more quietly without problems and quietly.

- No Lubrication Needed: Unlike chains that require oil, timing belts are easy and maintenance-free in terms of lubrication.

- Cleanliness: No oil method, no mess, which could be a huge plus in lots of commercial enterprise settings.

- Durability: Made with strong materials and bolstered cords, they may be built to closing, even though they do have a lifespan and require occasional replacement.

Types of Timing Belts

The core principle remains the same; timing belts come in different types, mainly categorized by their materials and tooth profiles:

Rubber timing belts are most popular; they are frequently composed of HNBR or neoprene rubber and reinforced with steel or fiberglass strands. They serve a diffusion of functions and are bendy.

Polyurethane timing belts are well-known for their high-quality resistance to wear and are, from time to time, bolstered with Kevlar or steel wires. They are regularly hired in settings that call for extreme precision and cleanliness.

Open-ended timing belts are to be had in prolonged rolls and can be trimmed to the required duration for programs concerning linear movement, together with 3D printers. After that, they're often clamped at both ends.

Endless timing belts are used to replace the strength among spinning shafts and are made as a non-preventive loop. Each kind of designed to meet specific demands regarding strength, flexibility, temperature resistance, and precision.

Although Timing synchronous belts might be hidden away in the machinery around us, their role in enabling precise, reliable, and efficient operation is undeniable. They are really the motion control unsung heroes.

Looking for more details or a complete catalog of our timing belts?

Dynamic Industrials is ready to help. Contact us today with your questions and needs.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.