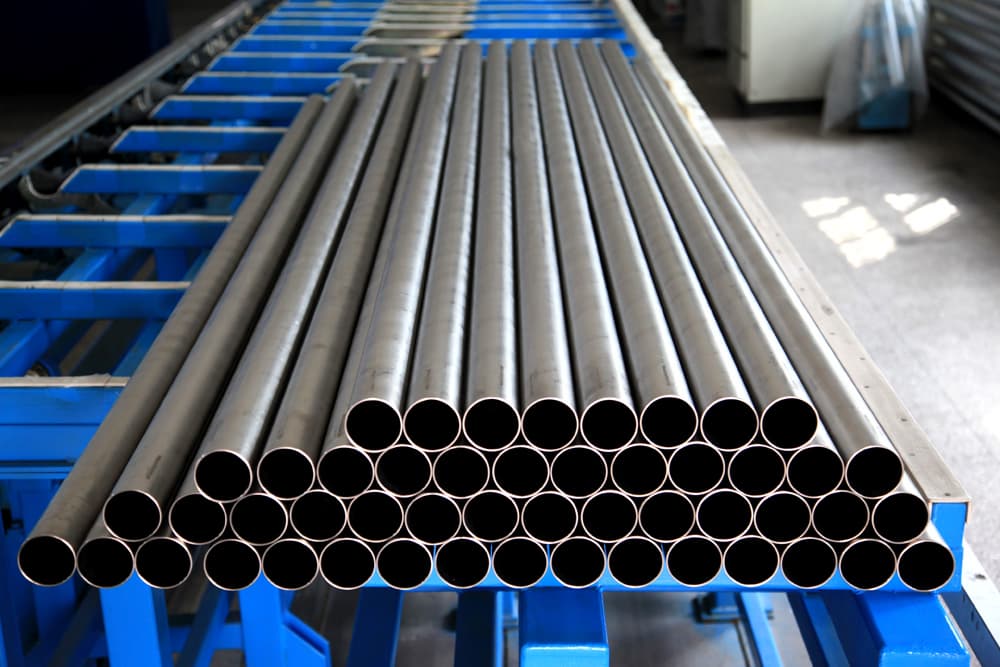

Unveiling the Excellence of 317L Stainless Steel ERW Pipes

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In the realm of stainless steel piping, the spotlight often shines on various grades that cater to specific industrial needs. Among these, 317L stainless steel stands out, known for its exceptional corrosion resistance and versatility. In this blog, we'll take a closer look at 317L stainless steel ERW pipes, exploring their unique features, applications, and the advantages they bring to diverse industries.

Understanding 317L Stainless Steel:

Stainless Steel 317L is an austenitic chromium-nickel-molybdenum alloy characterized by its low carbon content. This low carbon composition enhances its corrosion resistance, particularly in corrosive environments such as chemical processing plants and pulp and paper industries. When shaped into ERW pipes, 317L stainless steel becomes a reliable conduit for various applications.

Key Features of 317L Stainless Steel ERW Pipes:

Corrosion Resistance:

The hallmark feature of 317L stainless steel is its outstanding resistance to corrosion, particularly in harsh chemical environments. The alloy's composition, including molybdenum, provides robust protection against corrosive substances, making it ideal for applications where corrosion is a primary concern.

High Temperature Performance:

317L stainless steel retains its strength and integrity at elevated temperatures, making it suitable for applications involving heat and thermal processing. This property is particularly advantageous in industries such as petrochemicals, where high-temperature resistance is paramount.

Formability and Weldability:

The ERW manufacturing process imparts excellent formability to 317L ss pipes, allowing for seamless integration into complex piping systems. Additionally, the alloy maintains good weldability, facilitating efficient fabrication and customization as per specific industrial requirements.

Chemical Compatibility:

Due to its low carbon content and the inclusion of molybdenum, 317L stainless steel exhibits enhanced chemical compatibility. This feature makes it a preferred material for conveying corrosive chemicals and acids, especially in chemical and pharmaceutical industries.

Applications of 317L Stainless Steel ERW Pipes:

Chemical and Petrochemical Industries:

The corrosion-resistant nature of 317L stainless steel ERW pipes finds extensive use in chemical processing plants and petrochemical industries. These pipes play a crucial role in conveying corrosive substances without compromising on the integrity of the piping system.

Oil and Gas Processing:

In the oil and gas sector, where pipelines are subjected to harsh conditions and aggressive substances, 317L stainless steel ERW pipes provide a reliable solution. Their corrosion resistance and high-temperature performance make them well-suited for conveying oil, gas, and related products.

Pharmaceutical and Food Processing:

The chemical compatibility and hygienic properties of 317L stainless steel make it an ideal choice for conveying pharmaceutical and food products. These pipes are crucial in ensuring the integrity and cleanliness of processes in these highly regulated industries.

Pulp and Paper Industry:

Given its resistance to corrosion in acidic environments, 317L stainless steel ERW pipes find applications in the pulp and paper industry. They are used in conveying corrosive chemicals during various stages of paper production.

Conclusion:

Stainless Steel 317L ERW pipes embody the excellence of 317L stainless steel, offering a reliable solution for industries requiring corrosion-resistant, high-temperature performance. From chemical plants to food processing facilities, these pipes play a pivotal role in maintaining the integrity of critical processes. As industries evolve, the demand for 317L stainless steel ERW pipes is likely to persist, ensuring the continued prominence of this alloy in the realm of stainless steel piping.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.