Welding Consumables Market - Global Growth, Share, Trends, Demand and Analysis Report Forecast 2030

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

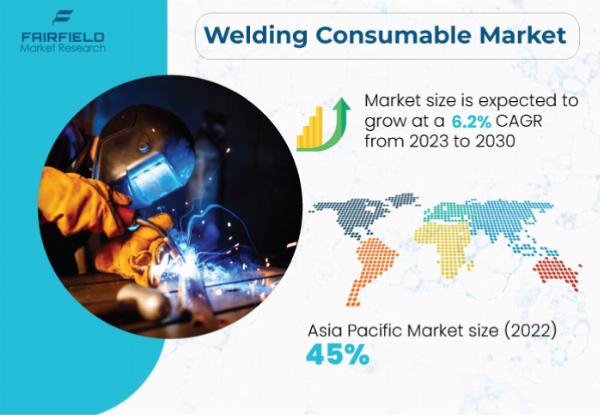

Global welding consumables market is expected to witness remarkable growth, reaching a value of US$19.2 billion by the year 2030, up from US$12.6 billion in 2022. According to a recent report, the market is projected to experience a compound annual growth rate (CAGR) of 6.2% between 2023 and 2030, fueled by various key factors driving demand and innovation in the industry.

Key Trends Driving Market Growth:

1. Growing Demand from Construction and Automotive Industries: The market is witnessing a surge in demand from the construction and automotive sectors, driven by increasing infrastructure projects and rapid urbanization worldwide. Welding consumables play a vital role in these industries, particularly in the fabrication and assembly of structural components.

• Technological Advancements Driving Innovation: Continuous innovation in welding technologies, such as automation, robotics, and Artificial Intelligence (AI), is enhancing the efficiency, precision, and safety of welding processes. Integration of these advanced technologies is streamlining operations and increasing productivity.

• Pacing Infrastructural Development: The global focus on infrastructural development, including investments in bridges, highways, railways, and commercial and residential spaces, is contributing significantly to the demand for welding consumables.

• Growing Emphasis on Sustainable Practices: There is a rising demand for environmentally friendly welding consumables as businesses worldwide prioritize sustainability. Manufacturers are investing in research and development to create eco-friendly alternatives, complying with stringent environmental regulations.

Major Growth Barriers:

1. High Raw Material Costs and Price Volatility: The market faces challenges due to fluctuations in the prices of metals, fluxes, and gases, which are essential components of welding consumables. Economic uncertainties and geopolitical factors contribute to price volatility, impacting manufacturing costs and profit margins.

2. Stringent Regulatory Compliance: Adherence to stringent environmental regulations and industry standards poses a significant challenge for market players. Meeting these regulations requires substantial investments in research and development to develop eco-friendly consumables, adding complexity and costs to manufacturers.

Key Trends and Opportunities to Look at:

1. Rapid Adoption of Automation and Robotics: Industries are increasingly integrating robotic welding systems for higher precision and efficiency, particularly in regions like North America and Europe. Brands are leveraging this trend by offering compatible consumables and specialized training to capitalize on the demand for robotic welding solutions.

2. Focus on Environmentally Friendly Consumables: There is a growing shift towards eco-friendly welding consumables, driven by stringent environmental regulations worldwide. Companies are developing green alternatives to comply with regulations and appeal to environmentally conscious consumers.

3. Digitalization and IoT Integration: Smart welding consumables embedded with sensors and IoT capabilities enable real-time monitoring and data analysis, gaining momentum globally. Companies are investing in advanced IoT integration to offer predictive maintenance services and enhance customer experiences through data-driven insights.

Regional Outlook:

1. Asia Pacific Tops with Unprecedented Infrastructure Growth: Asia Pacific remains the largest revenue-contributing region in the global welding consumables market, driven by robust industrial growth, rapid urbanization, and extensive infrastructural developments.

2. North America to Maintain 25% Share Through: North America is poised to witness significant growth in sales, fueled by technological advancements, innovation in welding processes and consumables, and a highly developed industrial sector.

Fairfield’s Competitive Landscape Analysis:

In the competitive landscape, manufacturers are differentiating through product innovation and quality, leveraging data analytics and IoT technology to enhance their offerings. Smart welding consumables offer real-time monitoring capabilities, optimizing welding processes and improving efficiency.

Leaders in Global Welding Consumables Space:

• Bavaria Schweisstechnik Gmbh

• Carboweld Schweissmaterialien Gmbh

• Colfax Corporation

• Corodur Verschleiss-Schutz Gmbh

• Daiko Welding Consumables

• Dim Schweissmaterial Manfred Schuermann

• Drahpo Gmbh

• Drahtwerk Elisental W. Erdmann Gmbh & Co.

• Durum Verschleissschutz Gmbh

• Elbor Spa

• Fidat Srl

• Fronius International Gmbh

• Gedik Welding

• Hermann Fliess & Co. Gmbh

• Voestalpine Ag

For more information: https://www.fairfieldmarketresearch.com/report/welding-consumables-market

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.