Which Demand Planning KPIs Matter Most for Business Success?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

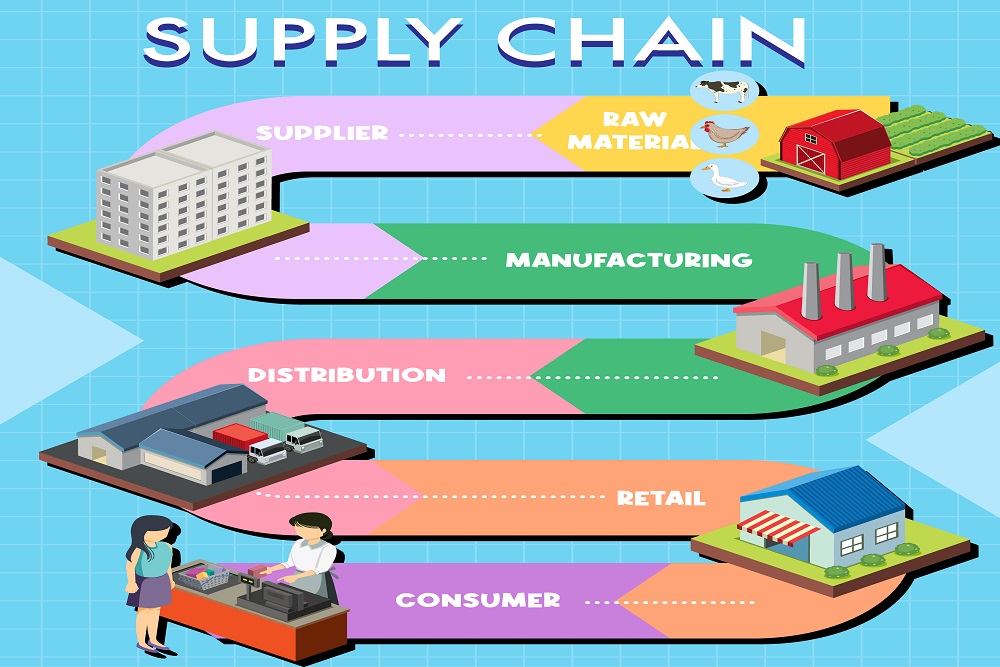

Demand planning is the backbone of an efficient supply chain. Businesses that fail to predict customer demand accurately risk stock shortages, overstocking, and financial losses. To ensure smooth operations, companies must track key performance indicators (KPIs) that measure the effectiveness of their demand planning strategies.

The right demand planning KPIs provide valuable insights into forecasting accuracy, inventory efficiency, and supply chain responsiveness. Businesses leveraging AI-powered tools like thouSense can analyze these KPIs in real time, allowing for data-driven decision-making and optimized operations.

In this blog, we’ll explore the most important demand planning KPIs that drive business success and explain how companies can use them to enhance forecasting accuracy and operational efficiency.

1. Forecast Accuracy: The Foundation of Demand Planning

Why Forecast Accuracy Matters

Reducing Stock Imbalances

Accurate demand planning ensures that businesses maintain optimal inventory levels. Poor forecasting leads to either stockouts, which disrupt sales, or excessive inventory, which ties up working capital.

Improving Supply Chain Efficiency

Forecast accuracy helps companies align their procurement, production, and logistics with actual demand, reducing waste and enhancing operational efficiency.

KPIs That Measure Forecast Accuracy

Mean Absolute Percentage Error (MAPE)

MAPE calculates the percentage deviation between forecasted and actual demand. A lower MAPE value indicates higher forecasting precision.

Forecast Bias

This KPI determines whether a company consistently over-forecasts or under-forecasts demand. A balanced bias ensures businesses maintain optimal stock levels without unnecessary excess or shortages.

2. Inventory Performance: Balancing Supply and Demand

Why Inventory Management is Crucial

Minimizing Holding Costs

Holding excessive inventory increases storage costs and risks obsolescence, particularly in industries with perishable or seasonal products.

Ensuring Product Availability

Poor demand planning can result in frequent stockouts, causing customer dissatisfaction and lost sales opportunities.

KPIs That Measure Inventory Efficiency

Inventory Turnover Ratio

This KPI measures how often inventory is sold and replaced over a given period. A high turnover ratio indicates strong demand planning, while a low ratio suggests overstocking or slow-moving products.

Days Sales of Inventory (DSI)

DSI calculates how long inventory remains in stock before being sold. Lower DSI values indicate that products move quickly, reducing holding costs and improving cash flow.

3. Customer Satisfaction: Meeting Market Demand

Why Customer-Focused Demand Planning Matters

Enhancing Customer Experience

Reliable demand planning ensures that businesses can fulfill customer orders on time, improving satisfaction and brand loyalty.

Minimizing Backorders and Delays

Frequent stock shortages force customers to wait or switch to competitors. Effective demand planning helps companies maintain product availability.

KPIs That Measure Customer Satisfaction

Order Fill Rate

This KPI measures the percentage of customer orders fulfilled on the first shipment. Higher fill rates indicate effective demand planning and inventory availability.

Stockout Rate

The stockout rate calculates how often items are unavailable when customers attempt to purchase them. A lower stockout rate signifies stronger inventory management and forecasting accuracy.

4. Supply Chain Responsiveness: Adapting to Market Changes

Why Supply Chain Agility is Critical

Handling Market Fluctuations

Businesses must be able to adjust to unexpected changes in demand, whether due to seasonal trends, economic shifts, or competitor actions.

Optimizing Supplier Coordination

An agile supply chain ensures that businesses can quickly respond to changes in demand by adjusting procurement and production schedules.

KPIs That Measure Supply Chain Responsiveness

Supplier On-Time Delivery Rate

This KPI tracks how reliably suppliers fulfill orders on schedule. A high percentage indicates smooth coordination and reduced risk of inventory disruptions.

Demand Variability

Demand variability measures fluctuations in customer demand over time. Businesses with stable demand patterns can optimize production, while high variability requires flexible supply chain strategies.

5. Financial Performance: The Profitability of Demand Planning

Why Financial KPIs Matter in Demand Planning

Reducing Excess Costs

Efficient demand planning reduces the costs associated with excess inventory, emergency shipments, and lost sales due to stockouts.

Improving Revenue Forecasting

Accurate demand planning allows businesses to project future sales revenue, aiding in budgeting and financial decision-making.

KPIs That Measure Financial Success

Gross Margin Return on Inventory Investment (GMROI)

GMROI calculates the profitability of inventory investments. Higher values indicate that inventory is being used effectively to generate revenue.

Cost of Goods Sold (COGS) as a Percentage of Revenue

Tracking COGS relative to revenue helps businesses assess whether they are managing procurement and production costs efficiently.

How thouSense Enhances Demand Planning KPIs

AI-Driven Forecasting for Improved Accuracy

Leveraging Data for Precision

thouSense analyzes historical sales data, market trends, and real-time demand fluctuations to enhance forecasting accuracy and reduce errors.

Predictive Analytics for Smarter Planning

With AI-powered insights, businesses can anticipate demand shifts before they occur, allowing them to adjust procurement and production proactively.

Optimizing Inventory Management with Automation

Reducing Overstock and Stockouts

thouSense helps businesses balance inventory levels by providing automated alerts for replenishment and stock optimization.

Real-Time KPI Monitoring

thouSense continuously tracks key demand planning KPIs, offering actionable insights that businesses can use to improve performance.

Best Practices for Tracking Demand Planning KPIs

1. Regularly Review KPI Performance

Monitoring demand planning KPIs on a monthly or quarterly basis ensures businesses stay on track with their goals and make data-driven improvements.

2. Integrate AI for Data Accuracy

AI-driven tools like thouSense reduce manual forecasting errors and improve the reliability of demand planning metrics.

3. Align KPIs with Business Objectives

Each business has unique goals—whether focused on customer satisfaction, cost reduction, or sales growth. Selecting the right KPIs ensures that demand planning efforts align with the overall company strategy.

4. Improve Supplier Communication

Coordinating with suppliers based on real-time demand insights ensures timely inventory replenishment and minimizes supply chain disruptions.

5. Adjust Strategies Based on KPI Insights

If KPI trends indicate inefficiencies—such as high stockout rates or poor forecast accuracy—businesses should adapt their planning approach accordingly.

Conclusion

Effective demand planning is impossible without tracking the right KPIs. From forecasting accuracy and inventory turnover to customer satisfaction and financial performance, demand planning KPIs provide businesses with crucial insights into supply chain efficiency.

With AI-powered tools like thouSense, companies can enhance demand planning by leveraging real-time data, predictive analytics, and automated inventory management. Investing in KPI-driven demand planning ensures businesses reduce costs, improve customer experience, and maintain a competitive edge.

By prioritizing these KPIs and continuously refining demand planning strategies, businesses can achieve sustainable growth and long-term success.

FAQs

1. What are the most important demand planning KPIs?

Key KPIs include forecast accuracy, inventory turnover ratio, order fill rate, stockout rate, and supplier on-time delivery rate.

2. How does demand planning impact customer satisfaction?

Accurate demand planning ensures products are available when needed, reducing stockouts and improving order fulfillment rates.

3. How can AI tools like thouSense improve demand planning KPIs?

thouSense uses predictive analytics and real-time data tracking to enhance forecasting accuracy, optimize inventory levels, and improve supply chain responsiveness.

4. What role does financial performance play in demand planning?

Tracking financial KPIs such as GMROI and COGS ensures that businesses maximize profitability while managing inventory and procurement costs effectively.

5. How often should businesses review demand planning KPIs?

Businesses should monitor KPIs regularly—monthly or quarterly—to adjust their strategies and maintain supply chain efficiency.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.