Why Hand Pallet Trucks Are the Smart Choice for Material Handling

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today's fast-paced industries, efficiency and safety go hand in hand—especially when it comes to material movement. Among the most widely used and reliable equipment for moving goods in warehouses, manufacturing plants, retail stores, and distribution centers is the pallet truck. Also known as a pallet jack or hand pallet mover, this simple yet powerful tool is indispensable for any business that deals with heavy loads.

Let’s explore why these trucks are considered a smart, economical, and sustainable solution for handling materials, with insights into types, applications, and benefits.

Versatile Types to Suit Every Industry

- Over time, pallet trucks have evolved into a variety of types to serve different operational needs:

- Low Profile Trucks – Designed for handling low-clearance pallets in tight spaces.

- Heavy Duty Trucks – Ideal for transporting extra-heavy loads, commonly found in manufacturing.

- High Lift Pallet Trucks – Enable the lifting of goods to a more ergonomic height.

- Weigh Scale Trucks – Allow users to weigh goods in transit, saving time.

- Stainless Steel Trucks – Used in clean environments such as food and pharma industries due to their resistance to corrosion.

- Rough Terrain Trucks – Built with stronger wheels and frames to handle outdoor or uneven surfaces.

- Electric Pallet Movers – Motor-powered variants designed for high-volume operations with minimal operator fatigue.

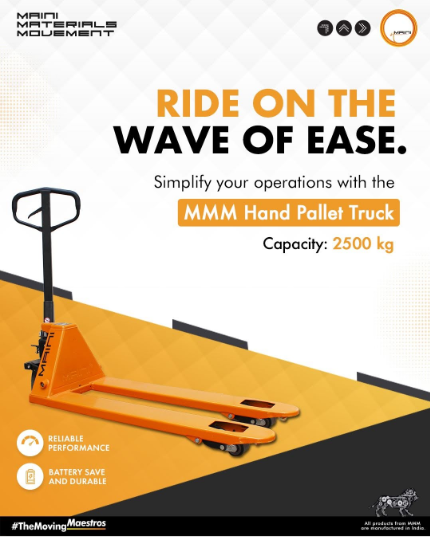

Brands like Maini Materials Movement offer robust and precision-engineered models to cater to various industrial demands, emphasizing ergonomics, safety, and reliability.

Key Benefits of Using Hand Pallet Trucks

1. Cost-Effective Investment

Compared to forklifts or motorized loaders, hand pallet trucks are significantly more affordable, both in terms of purchase and maintenance. Their durability and long service life mean fewer replacements, making them a smart choice for small and large businesses alike.

2. Ease of Use

No license, training, or certification is required to operate a hand pallet mover, making it accessible to any employee. With straightforward controls, minimal learning curve, and simple maneuverability, workers can begin using it with confidence in no time.

3. Improved Workplace Safety

Manual lifting and carrying of heavy materials can lead to injuries. Using a pallet truck helps reduce physical strain, enhances load stability, and allows for safer operations within crowded warehouse floors or narrow retail aisles.

4. Efficiency and Productivity

These tools streamline movement by allowing staff to move multiple items at once, cutting down the number of trips required. When integrated into a warehouse system, they can significantly reduce handling time and optimize labor productivity.

5. Minimal Maintenance

With few mechanical components, hand pallet trucks require only basic care—occasional lubrication, checking hydraulic fluid levels, and keeping wheels clear of debris. This results in very low downtime and repair costs.

6. Compact and Space-Saving

Their compact size enables them to fit through tight corridors, elevators, and between storage racks. This is particularly useful in retail and urban logistics spaces where every square foot matters.

Common Applications Across Industries

- Warehousing – Efficient storage and transport of goods within facilities.

- Retail – Stock replenishment and store layout changes.

- Logistics & Transportation – Loading and unloading deliveries.

- Manufacturing – Moving raw materials and finished goods along production lines.

- Healthcare – Transporting medical supplies in hospitals with minimal noise.

- Construction – Carrying building materials on-site.

- Food Processing – Safe movement of packaged items in clean zones.

- Agriculture – Handling produce or supplies in open and enclosed spaces.

Whether in a supermarket or a large factory, the utility of pallet trucks spans across sectors.

Choosing the Right Pallet Truck

When selecting a hand pallet truck, consider the following:

- Load Capacity – Match the truck’s lifting strength with your average load weight.

- Fork Length & Width – Choose dimensions compatible with your pallet size.

- Material & Build – Stainless steel or heavy-duty steel for longevity in tough environments.

- Terrain – Select rough-terrain models for outdoor or uneven surfaces.

Ergonomics – Opt for models with easy-grip handles and smooth movement to reduce operator fatigue.

A quality manufacturer like Maini Materials Movement focuses on delivering thoughtfully designed material handling solutions that prioritize performance, worker comfort, and safety. Their range of pallet trucks is built to handle the demands of diverse work environments.

Final Thoughts

As businesses push for more efficient and safe ways to handle materials, the humble hand pallet mover remains an unbeatable option. It combines simplicity, durability, and cost-effectiveness into a single piece of equipment. Whether you're expanding your storage capacity or upgrading your material movement tools, investing in a reliable hand pallet mover is a decision you won’t regret.

Smart logistics starts with the right tools—and in this case, the right truck.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.