Why Lockout Hasps are Essential for Electrical and Mechanical Safety

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

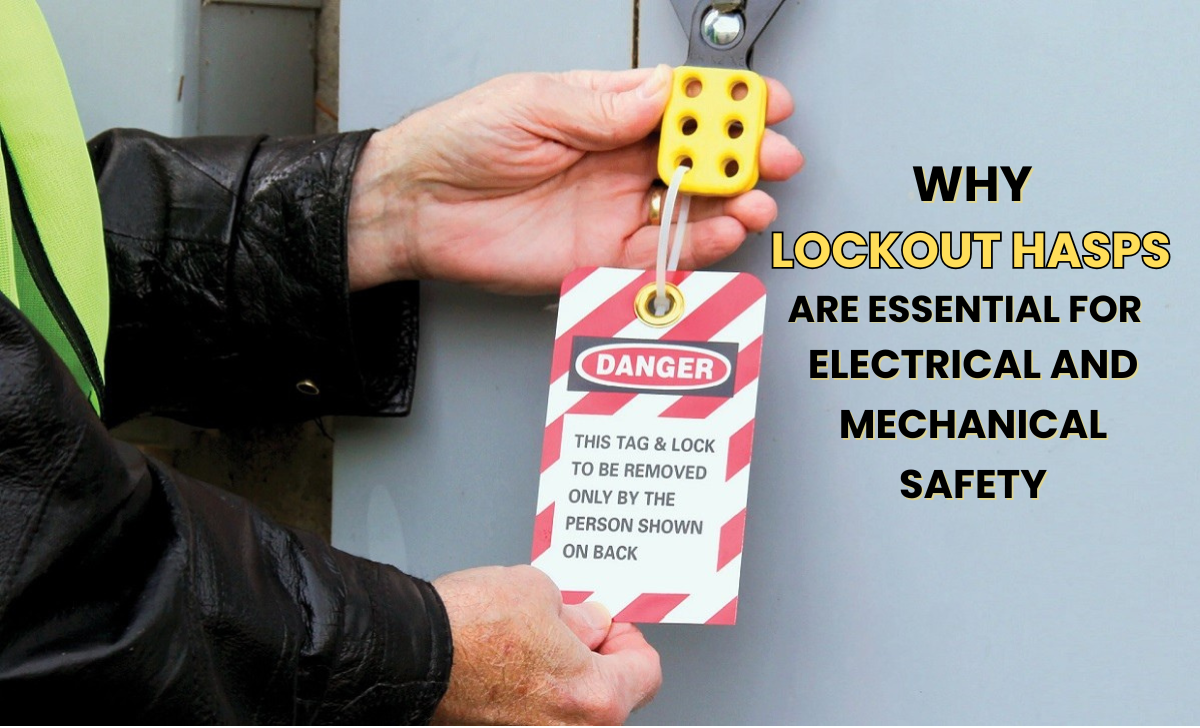

In industries where electrical and mechanical equipment is integral to operations, safety is paramount. The potential for accidents, injuries, or even fatalities due to uncontrolled energy sources is a constant concern. Lockout hasps, a critical component of lockout tagout systems, play an essential role in ensuring worker safety by preventing the unexpected release of hazardous energy. This article explores why lockout hasps are indispensable for electrical and mechanical safety, highlighting their functionality, benefits, and regulatory importance.

What are Lockout Hasps?

A lockout hasp is a robust safety device designed to secure energy isolation points, such as circuit breakers, valves, or switches, during maintenance or repair. Key features include:

Material: Typically made of durable steel or nylon to withstand industrial environments.

Design: Features multiple holes to accommodate several padlocks, allowing multiple workers to secure the device.

Function: Physically prevents equipment operation until all padlocks are removed, ensuring a zero-energy state.

Lockout hasps are integral to LOTO procedures, which control hazardous energy sources like electricity, hydraulic pressure, or mechanical motion.

Enhancing Electrical Safety:

Electrical systems present significant risks, including shocks, arc flashes, and electrocution. Lockout hasps mitigate these dangers by isolating electrical energy sources. Their role in electrical safety includes:

Secure Isolation: Lockout hasps secure circuit breakers or switches in the "off" position, preventing accidental re-energization.

Group Lockout: Enable multiple workers to attach personal padlocks, ensuring no single individual can restore power prematurely.

Risk Reduction: Minimize the chance of electrical accidents caused by miscommunication or oversight during maintenance.

By facilitating safe electrical work, lockout hasps protect workers from life-threatening hazards.

Ensuring Mechanical Safety:

Mechanical equipment, such as presses, conveyors, or rotating machinery, poses risks like crush injuries or amputations if energy is not properly controlled. Heavy-duty or Steel Lockout hasps enhance mechanical safety by:

Isolating Energy Sources: Secure valves, levers, or other controls to prevent unexpected movement.

Controlling Stored Energy: Lock out hydraulic, pneumatic, or spring-loaded systems to eliminate residual energy hazards.

Versatile Application: Suitable for various mechanical systems, from small valves to large industrial machines.

Lockout hasps ensure equipment remains in a safe, de-energized state, protecting workers from mechanical hazards.

Compliance with Safety Regulations

Lockout hasps are not just a best practice; they are often a legal requirement. In the United States, the Occupational Safety and Health Administration (OSHA) mandates the use of LOTO procedures under standard 29 CFR 1910.147 to control hazardous energy. Lockout hasps are explicitly recommended in this standard because they provide a reliable means of securing energy isolation points.

Non-compliance with LOTO regulations can result in hefty fines, legal liabilities, and, most importantly, preventable injuries. By incorporating lockout hasps into safety protocols, employers demonstrate a commitment to worker protection and regulatory adherence. Regular training on the proper use of lockout hasps further ensures that employees understand their role in maintaining a safe workplace.

Additional Benefits of Lockout Hasps:

Beyond safety and compliance, lockout hasps offer practical advantages, including:

Cost-Effective: Affordable tools with significant safety benefits.

Ease of Use: Simple to install and operate, requiring minimal training.

Durability: Built to withstand harsh conditions, ensuring long-term reliability.

High Visibility: Often brightly colored or labeled for high visibility, reducing the risk of operation errors by unauthorized personnel.

Maintenance-Free: They require little to no upkeep, making them a low-maintenance safety solution.

These benefits make lockout hasps a practical and efficient choice for industrial safety.

Conclusion

Lockout hasps are indispensable for electrical and mechanical safety in industrial environments. By enabling secure energy isolation, supporting group lockout procedures, and ensuring adherence compliance with regulations, they significantly reduce the likelihood of workplace accidents. Their simplicity, durable robust design, and versatility make them a critical component of any LOTO program. For employers and workers, investing in high-quality lockout hasps is a small investment for a major step toward a safer workplace, providing both protection and peace of mind.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.