Why Lockout Safety Padlocks are Essential for Energy Isolation

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

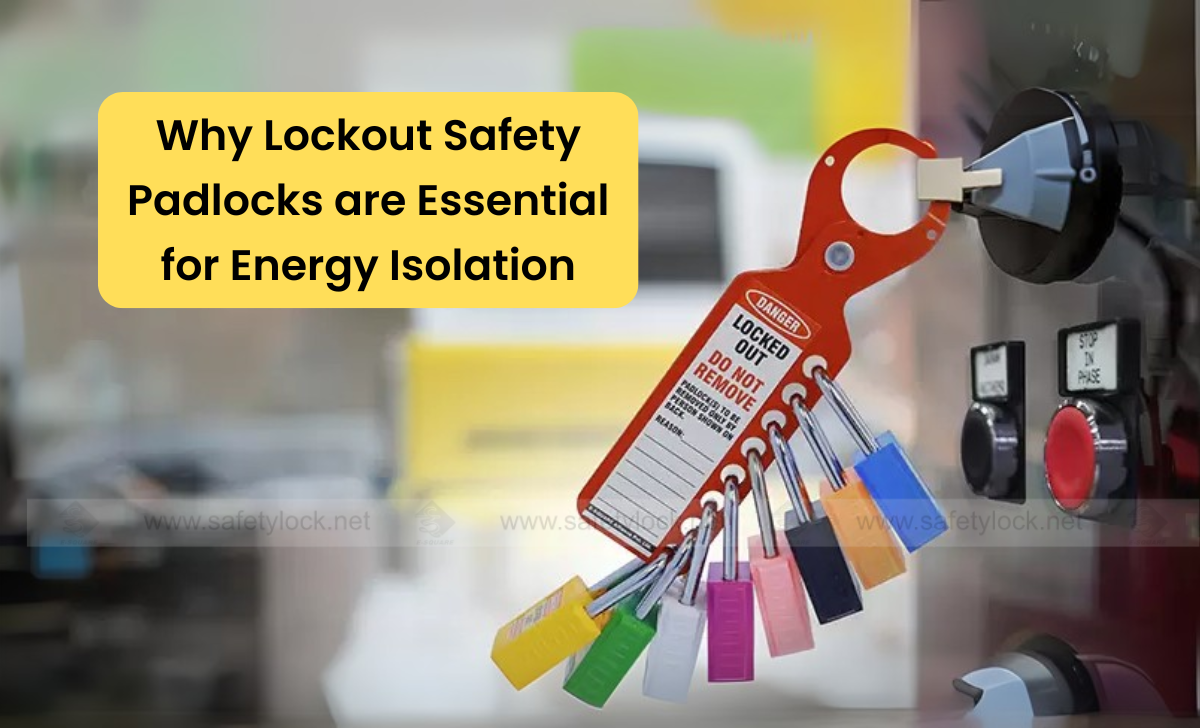

In industrial and workplace environments, ensuring the safety of employees is a top priority. One of the most effective safety measures to prevent accidents during equipment maintenance and servicing is the Lockout Tagout system. A crucial component of any LOTO program is the lockout safety padlock. These specialized padlocks provide a secure means of isolating energy sources, ensuring that machinery and electrical systems remain in a de-energized state until maintenance is safely completed. This article explores why lockout safety padlocks are essential for energy isolation and how they contribute to workplace safety.

The Role of Lockout Safety Padlocks in Energy Isolation

Lockout safety padlocks are specifically designed to control hazardous energy during maintenance activities. Their primary function is to lock out switches, valves, circuit breakers, and other energy sources to prevent unexpected re-energization, which could result in serious injuries or fatalities. Unlike standard padlocks, lockout safety padlocks are engineered with unique features that make them more reliable for workplace safety applications.

Key Features of Lockout Safety Padlocks:

Non-Conductive Materials: Many lockout safety padlocks are made from non-conductive materials such as thermoplastics, ensuring they are safe for use in electrical environments.

Unique Keying Systems: Lockout padlocks often come with unique keying options, such as keyed-different or master-keyed systems, to ensure that only authorized personnel can remove the lock.

Highly Visible Design: Available in bright colors, these padlocks enhance visibility and indicate that maintenance work is in progress, preventing accidental operation.

Durability and Weather Resistance: Designed for industrial use, these padlocks are resistant to extreme temperatures, chemicals, and harsh environments.

Compliance with Safety Standards: Lockout safety padlocks meet international safety regulations such as OSHA’s 29 CFR 1910.147 standard, ensuring legal compliance.

Why Lockout Padlocks are Essential for Workplace Safety?

1. Prevention of Workplace Accidents: The primary purpose of lockout padlocks is to prevent accidental machine activation, which could lead to electrocution, mechanical injuries, or exposure to hazardous substances.

2. Regulatory Compliance: Government safety agencies require businesses to implement energy isolation procedures. Using lockout padlocks ensures adherence to these regulations, reducing the risk of fines and legal issues.

3. Protection of Maintenance Personnel: Employees working on de-energized equipment can perform their tasks without fear of sudden power restoration, leading to a safer work environment.

4. Standardization of Safety Procedures: Implementing lockout safety padlocks as part of a LOTO program helps establish a standardized approach to energy isolation, ensuring consistency across departments and facilities.

5. Reduction in Equipment Downtime: Proper energy isolation with lockout padlocks reduces the likelihood of equipment damage caused by unexpected startups, leading to lower maintenance costs and increased operational efficiency.

How to Implement Lockout Safety Padlocks Effectively?

Implementing a lockout padlock on equipment or lockout devices is very easy, just remember a few things to make it effective.

1. Identify Hazardous Energy Sources: Conduct a thorough assessment of all equipment and machinery that require energy isolation.

2. Develop a Lockout/Tagout Program: Establish clear procedures for locking out equipment, assigning responsibilities, and training employees.

3. Use the Right Lockout Padlocks: Choose padlocks that are suitable for the specific energy sources in your facility, ensuring durability and compliance.

4. Train Employees on Proper Usage: Educate workers on the importance of lockout safety padlocks and how to use them correctly.

5. Regularly Inspect and Maintain Lockout Equipment: Conduct periodic audits to ensure lockout padlocks are in good condition and being used properly.

Conclusion

Lockout safety padlocks are an essential component of any energy isolation procedure, ensuring that equipment remains securely locked out during maintenance. Their role in preventing workplace accidents, ensuring compliance with safety regulations, and protecting workers from hazardous energy sources cannot be overstated.

By implementing a well-structured lockout program and using high-quality lockout padlocks, organizations can create a safer work environment and minimize the risks associated with uncontrolled energy releases. Investing in lockout safety padlocks is not just a safety measure; it is a commitment to the well-being of employees and the efficiency of industrial operations.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.