Tiered Link Strategy – Multiply Your SEO Impact Today!

Tiered Link Strategy – Multiply Your SEO Impact Today!

Why Maintenance Is Required for Mechanic Work Lights to Ensure Longevity?

Written by gjigjiguy » Updated on: October 23rd, 2024

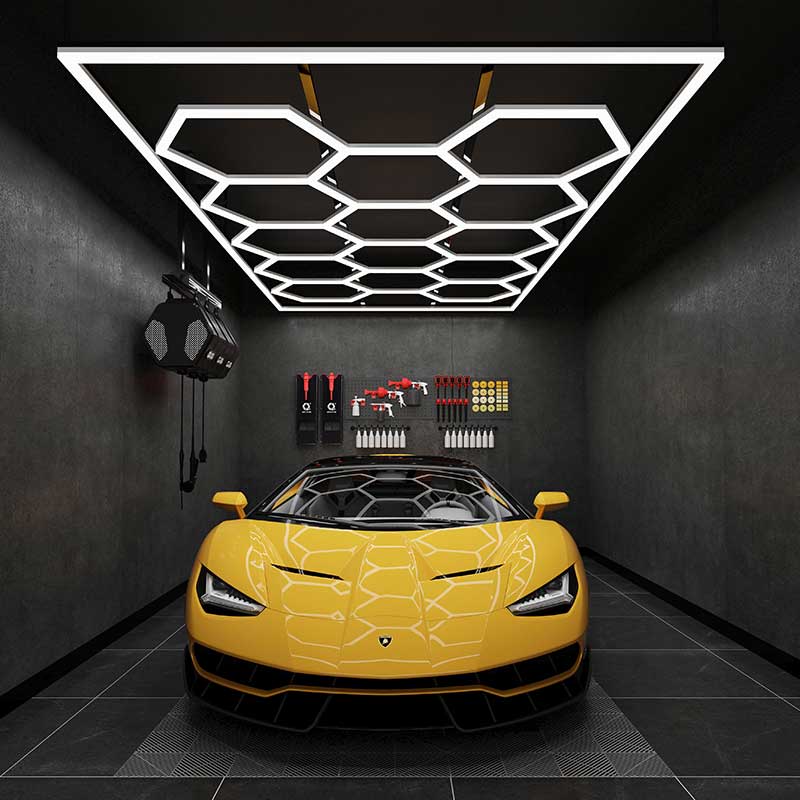

Mechanic work lights are essential tools in automotive repair shops, providing the necessary illumination for detailed inspections and repairs. Among various types, LED lights hexagon mechanic work lights stand out for their efficiency and effectiveness. However, like any tool, their longevity depends significantly on proper maintenance. This article delves into the importance of maintenance for mechanic work lights, specifically focusing on LED hexagon designs.

Understanding LED Hexagon Mechanic Work Lights

LED lights hexagon car care lights offer several advantages, including energy efficiency, durability, and adjustable lighting angles. Their unique hexagonal design allows for a broader distribution of light, reducing shadows and enhancing visibility in intricate repair tasks. Despite these benefits, neglecting maintenance can lead to performance issues and shortened lifespans.

Importance of Regular Cleaning

One of the simplest yet most critical maintenance tasks is regular cleaning. Dust, grease, and debris can accumulate on the surface of the lights, diminishing their brightness and overall effectiveness. For LED lights hexagon working lights, which often have multiple facets, it’s vital to clean all angles to ensure optimal light output. Using a soft cloth and non-abrasive cleaner can help maintain clarity without damaging the surface.

Checking Electrical Components

Regularly inspecting the electrical components of LED lights hexagon auto repair lights is essential. Loose connections or damaged wiring can lead to flickering or complete failure. Mechanics should check all cords and connectors for wear and tear, replacing any faulty components promptly. This proactive approach helps prevent larger issues that could arise from neglected wiring, ultimately extending the lifespan of the lights.

Ensuring Proper Ventilation

LED lights hexagon for garage auto detail repair shop lights generate some heat during operation. Ensuring proper ventilation around the lights is crucial to prevent overheating, which can lead to reduced brightness and lifespan. Mechanics should avoid placing hexagon LED car work lights in enclosed spaces without adequate airflow. Additionally, checking for any obstructions around the lights that might trap heat is essential for maintaining performance.

Regularly Inspecting Mounting and Stability

The stability of mechanic work lights is vital for both safety and performance. LED lights hexagon for detailing should be securely mounted or placed in a stable position to prevent accidental falls or shifts during use. Regularly inspecting the mounting hardware and ensuring it remains tight and secure can help avoid accidents that may damage the lights or cause injury.

Testing for Light Output

Over time, the brightness of LED lights hexagon garage can diminish. Regularly testing the light output of hexagon LED auto beauty lights ensures they are performing at optimal levels. If a significant reduction in brightness is observed, it may indicate that the lights need replacement or maintenance. Keeping a consistent brightness is essential for detailed work, where precision is crucial.

Addressing Environmental Factors

The environment in which LED lights hexagon car care lights operate can significantly affect their longevity. Exposure to moisture, extreme temperatures, or corrosive substances can lead to premature failure. Mechanics should be aware of their shop's environmental conditions and take steps to protect their lights. For instance, using waterproof covers or storing lights in dry areas can help mitigate potential damage.

Conclusion

Maintaining LED lights hexagon automotive work lights is vital for ensuring their longevity and effectiveness in automotive repair shops. Regular cleaning, inspecting electrical components, ensuring proper ventilation, checking stability, testing light output, and addressing environmental factors are all essential practices that can significantly extend the lifespan of these valuable tools. By investing time in maintenance, mechanics can ensure that their work lights remain reliable, enhancing both safety and productivity in their workspaces.

Disclaimer: We do not promote, endorse, or advertise betting, gambling, casinos, or any related activities. Any engagement in such activities is at your own risk, and we hold no responsibility for any financial or personal losses incurred. Our platform is a publisher only and does not claim ownership of any content, links, or images unless explicitly stated. We do not create, verify, or guarantee the accuracy, legality, or originality of third-party content. Content may be contributed by guest authors or sponsored, and we assume no liability for its authenticity or any consequences arising from its use. If you believe any content or images infringe on your copyright, please contact us at [email protected] for immediate removal.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.