Why Poor Racking Still Causes Warehouse Accidents in 2025?

Safety is an integral part of any industrial warehouse or storage facility — it is more than a checklist item. In spite of this, the use of poorly-fitted racking systems is one of the most overlooked causes of warehouse accidents. From collapsed shelves to falling inventory, the risks are substantial.

We will discuss how poor racking choices directly lead to warehouse accidents and why it is important that every warehouse considers Heavy-Duty Racking Systems as a smart, safe investment to make.

The Real Dangers of Poor Racking

A warehouse stores tons of inventory - sometimes quite literally. When your racks do not meet structural requirements or are not designed to handle the kind of loads you encounter, you are at risk.

Common problems with low-quality or mismatched industrial racking systems include:

Overloaded beams that bend or collapse

Leaning uprights or unstable base plates

Improper anchoring to the warehouse floor

Rust, corrosion, or material fatigue

No safety clips or back mesh to prevent falling products

Such structural weaknesses can lead to serious warehouse safety hazards — injuries to workers, product loss, and operational downtime. Worse, these failures often happen without warning.

Why Heavy Duty Racking Systems Are the Safer Choice

There are several advantages to heavy-duty racks which have been engineered for use in industrial environments, allowing them to handle heavy loads, frequent wear and tear, and rough handling. These racks are made from high-tensile steel and precision-engineered components, which make them capable of withstanding heavy loads, frequent wear and tear.

Here’s what sets them apart:

We design custom warehouse racks based on the actual weight and size of your inventory in order to provide you with a load capacity that meets reality.

The structures are designed with reinforced frames, cross-beam locking, and test welds that will not budge under pressure.

Industrial storage racks are available with powder coated or galvanized finishes for long-term durability.

Custom Fit to Floor LayoutAvoids awkward overhangs or weak structural zones caused by misfit racks.

Integrated Safety FeaturesOptions like rack guards, aisle protection, and anti-collapse mesh for enhanced racking safety.

Automated Manufacturing = Higher Safety Standards

The automated racking systems we use at Sigma Racks ensure that all bolts, beams, and brackets meet consistent quality and alignment standards, which ensures that there are no weak links.

Compared to manual or semi-assembled systems, automation gives:

Precision tolerances

Consistent welds

Zero human error in alignment

Faster production without cutting corners

When you’re dealing with hundreds of kilos per rack, that precision can make the difference between safe operations and a disaster waiting to happen.

The Hidden Costs of Unsafe Racks

It has been observed that many businesses believe that they are saving money by using low-cost shelving when, in fact, what they are actually doing is increasing the costs of the shelving themselves as a result:

Damaged inventory

Higher worker compensation claims

Downtime due to warehouse safety violations

Fines for unsafe practices

Poor morale in unsafe environments

Instead of facing recurring losses, investing once in certified heavy duty racking systems can save lakhs over time.

Safety + Efficiency = Smarter Warehouse

The right Warehouse Storage Solutions don’t just prevent accidents — they improve workflow:

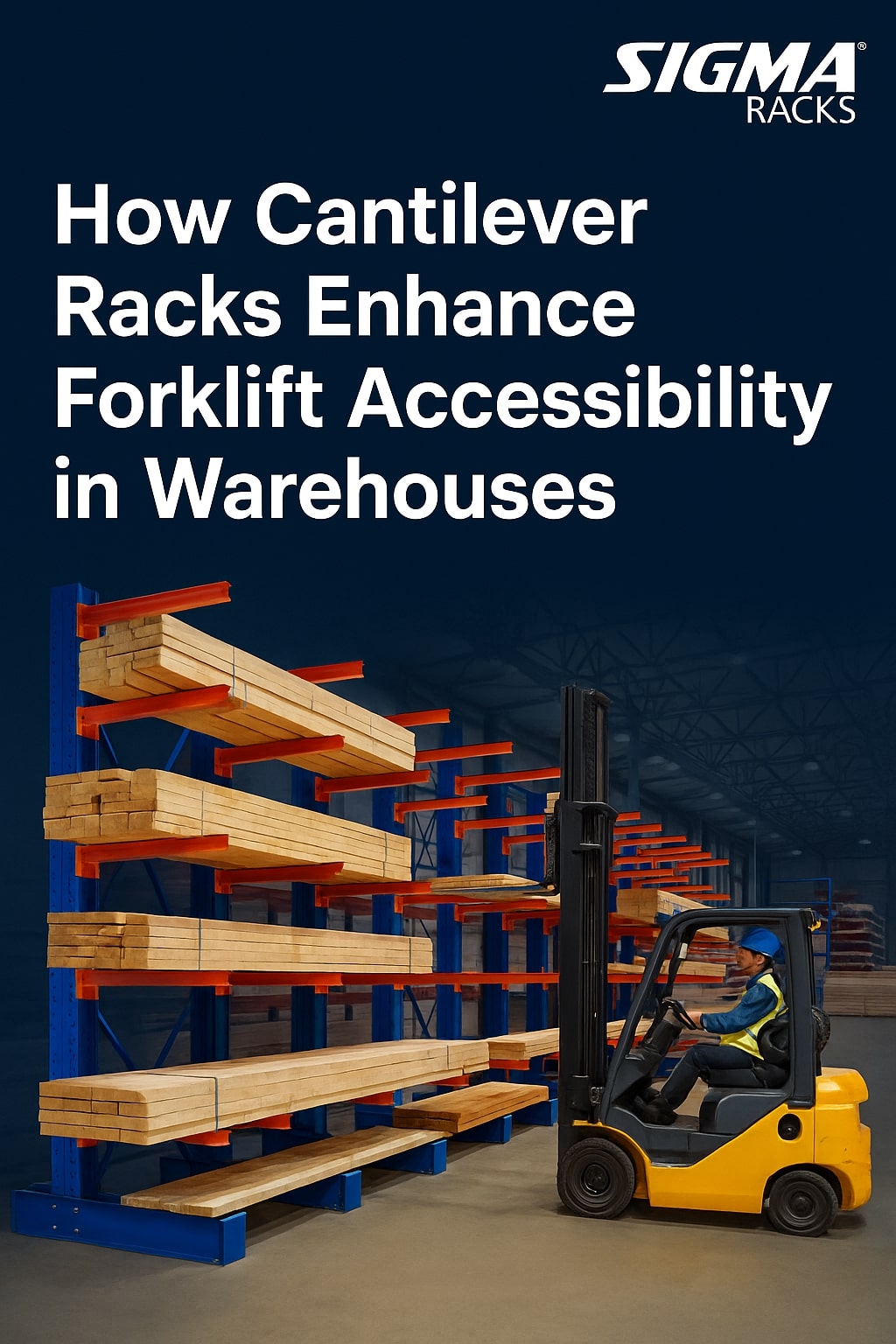

Better aisle spacing for forklifts

Faster picking with clearer zones

Safer stacking and unstacking

Less product damage during movement

When safety and structure work hand-in-hand, your warehouse becomes more than just a storage space — it becomes a performance engine.

Build it Right with Sigma Racks

As a manufacturer direct rack provider, Sigma Racks helps businesses design and install heavy duty racking solutions to meet their exact requirements - no overengineering, no underperformance, all our racks are load-tested, layout-optimized, and built using robotic technologies.

Whether you’re upgrading an outdated system or planning a new warehouse, we’ll make sure your Industrial Racking Systems don’t just hold goods — they protect your people.

📲 Ready to upgrade your warehouse safety?

Call us at +91-9670777737

Because a safe warehouse doesn’t start with policy — it starts with your racking.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.