Why Quality Sheet Metal Fabrication Drafting is Key to Manufacturing Success

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

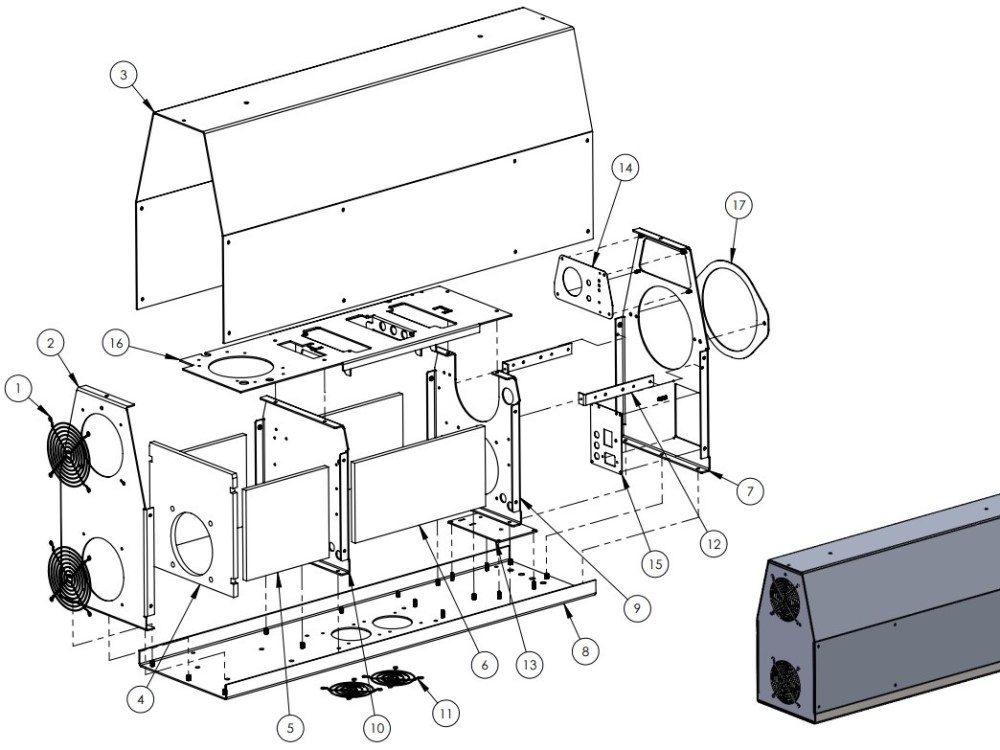

Sheet Metal Fabrication Drawing Services play a vital role in bridging the gap between design and manufacturing by providing clear, accurate, and detailed documentation essential for precise fabrication. By incorporating critical details such as dimensions, tolerances, and material types, well-crafted drawings support seamless communication between engineers, fabricators, and assembly teams. With industry-standard practices and advanced CAD tools, sheet metal drawings enhance productivity, streamline workflows, and improve the overall quality of the finished product.

1. The Importance of Accurate Drafting in Fabrication

Drafting is more than just creating blueprints. In the context of sheet metal fabrication, it means delivering clear and detailed representations of every component and assembly. Proper mechanical drafting services allow fabricators to understand exact dimensions, tolerances, bends, and joining methods, ensuring that no part is misinterpreted or poorly fabricated.

Inaccurate or poorly created drafts can lead to serious issues such as:

- Wasted material due to rework or errors

- Delays in the production line

- Increased labor and operational costs

- Safety concerns due to flawed components

2. Enhancing Communication Between Teams

One of the core benefits of high-quality drafting is improved coordination. When fabrication teams, engineers, and project managers are working from the same detailed drawings, there’s less room for confusion. Drafting also plays a central role in aligning vendor specifications, machine capabilities, and client expectations.

Whether it’s a small business or a large industrial facility, sheet metal shop drawings serve as a shared language across departments, ensuring everyone is on the same page.

3. Adherence to Industry Standards and Compliance

Quality drafting ensures that drawings align with established industry standards like ANSI, ISO, or company-specific requirements. This is particularly critical in sectors like:

- HVAC

- Aerospace

- Automotive

- Heavy Equipment

By following Sheet Metal Drawing Standards, companies can ensure that their products are compliant, safe, and suitable for global supply chains.

4. Optimizing Design for Manufacturability (DFM)

High-quality sheet metal detailing services allow for DFM principles to be integrated early in the process. Drafting experts can analyze how parts will be manufactured and assembled, reducing the risk of impractical designs or excessive production steps.

Key considerations include:

- Reducing part complexity

- Improving nesting efficiency

- Designing for standard tooling and equipment

- Ensuring easy assembly and maintenance

- This proactive approach lowers production costs and increases throughput.

5. The Role of Advanced CAD Tools

Modern drafting relies heavily on CAD technologies such as AutoCAD, SolidWorks, and Inventor. These tools not only improve drafting accuracy but also allow for real-time collaboration and rapid revisions. They support both 2D and 3D modeling, simulate fabrication outcomes, and generate detailed sheet metal fabrication drawings compatible with CNC machines.

With these tools, teams can:

- Model complex geometries

- Identify design flaws before production

- Share files digitally for faster approvals

- Maintain consistency across projects

6. Scalability and Outsourcing Advantages

As industries expand, so do their design needs. Quality drafting allows for scalability by creating modular, standardized, and easily replicable drawings. Companies can also outsource sheet metal drafting services to trusted partners, gaining access to specialized expertise and reducing in-house workload.

7. Why Choose As Industries

At the core of effective fabrication is a drafting partner you can rely on. As Industries is a recognized leader in Sheet Metal Design Services, offering a wide range of solutions including:

- Sheet Metal Shop Drawings Services

- Sheet Metal Fabrication Drawing Services

- SolidWorks Sheet Metal Drawing Services

- Sheet Metal Modeling Services

With a team of experienced engineers and CAD professionals, As Industries supports HVAC, automotive, and industrial manufacturing sectors with drafting solutions that meet global standards and deliver production-ready documentation with accuracy and speed.

In conclusion, quality sheet metal fabrication drafting is a strategic investment that leads to improved efficiency, reduced costs, and a higher standard of finished products. It ensures every part is made right the first time, supporting smoother operations and stronger results.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.