Why Rebar Detailing is More Than Just Steel Placement – The Hidden Science Behind Reinforcement

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

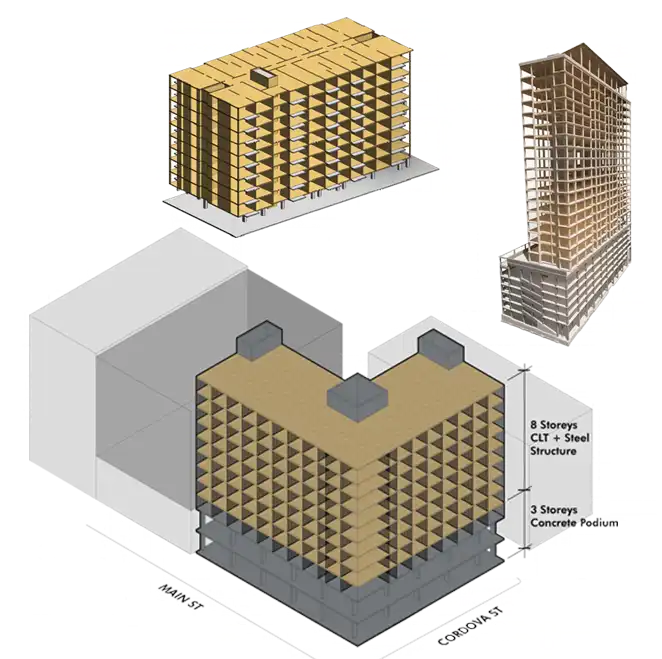

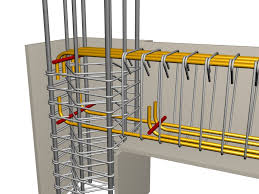

Rebar Detailing is often seen as a direct process of steel reinforcement within solid structures. However, there is a hidden science behind it that ensures structural integrity, durability and security of buildings and infrastructure. From accurate calculations to the rebar shop drawing, the process includes engineering expertise and advanced technology to meet the construction standards. In this blog, we will detect the role of advanced software such as the deep aspects of rebar detailing, AutoCAD rivers, and how a reliable rebar detailed company plays an important role in the success of a project.

Science behind rebar detailing

Rebar detailing is more than making pictures only. This includes accurate engineering that takes into account the forces working on structure, load distribution and construction feasibility. The following aspects define the hidden science of reinforcement:

1. Structural load idea

Rebar detailing ensures that the reinforcement can handle the load. A structure will cope throughout its lifetime. Engineers use structural rebar images to calculate bending moments, shear forces and axial loads, ensuring that every time it is deployed for optimal power.

Additionally, earthquakes and air loads are carefully assumed in detail to increase structural stability in areas suffering from earthquake and extreme weather conditions.

2. Concrete and steel interaction

The rebar is embedded in concrete to increase tensile strength, as concrete alone is weak in stress. The appropriate rebar drawing ensures that reinforcement is kept correctly to allow the formation of a spontaneous relationship between steel and concrete, to prevent structural failure. Concrete mixture, treatment process and temperature ups and rashes are also spread in rebar detailing .

3. Durability and Corrosion Resistance

Appropriate detailing helps to keep the reinforcement from moisture and corrosive elements. Proper details such as spacing and cover thickness, which are included in Retaining Wall Rebar Detail and Column Rebar Detail, are effective in increasing the service life of structures. Protective coatings like epoxy-coated rebar and galvanized steel help in corrosion resistance, especially in marine and industrial applications.

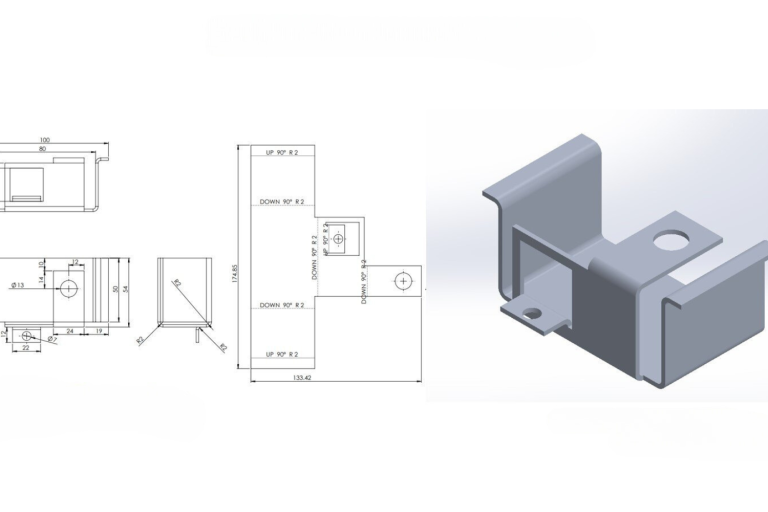

Importance of Rebar Shop Drawings

Rebar shop drawings are of great importance in construction projects. They serve as a guideline for placing, bending, and cutting of the different sizes of reinforcement bars. Some of the major aspects of shop drawings are:

Bar Bending Schedules (BBS) – A complete list showing the count, length, and shape of each piece of rebar.

Lap Splicing and Anchorage Details – Ensures without undermining structural strength that reinforcement is continuous in the proper manner.

Bar Marking and Tagging – All rebars will thus be easy to identify during construction.

Rebar Shop Drawings are produced using software tools like AutoCAD Rebar Detailing and Tekla Rebar Detailing, which both offer automation to the detailing process and ensure conformity to project requirements. It is the very accuracy of the drawings that help to meet on-site misinterpretation and land wastage of material to a great extent, helping in economical execution.

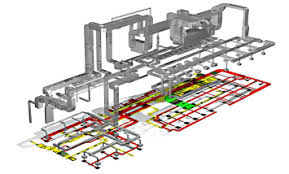

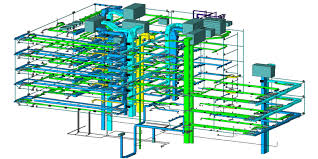

Software and Technologies in Rebar Detailing

With the growth of technology, Rebar Detailing improved in accuracy and efficiency. Now detailers can make detailed drawings, which are clash-free due to modern software such as Rebarcad, AutoCAD, and Tekla Rebar.

AutoCAD Rebar Detailing- widely used for 2D and 3D reinforcement drawings providing an accurate output.

Tekla Rebar Detailing- a 3D modeling environment to visualize and analyze reinforcement placement.

Rebarcad- framework is developed for rebar detailing, which provides features for rapid scheduling of bars and automatic detailing.

Further, the integration of Building Information Modeling (BIM) has changed the landscape of rebar detailing by promoting collaboration amongst architects, engineers, and contractors. BIM facilitates enhanced visualization, conflict detection capabilities, and real-time updates in construction workflows.

Reasons for Choosing a Professional Rebar Detailing Company

Using a specialist rebar detailing company will ensure compliance with industry standards, resource-efficient material usage, and timely completion. Some of the benefits of outsourcing rebar detailing services are:

Accuracy and Precision: By avoiding errors and reducing material wastage, specialist detailers guarantee a good production of Rebar Detailing Drawings.

Time and Cost Savings: Life cycle and error-free drawings reduce rework and delays in the project.

Conformity to Industry Standards: The people involved are well familiar with codes such as ACI, ASTM, and BS standards applicable for project compliance.

Coordination of the Project Betterment: Professional detailers will coordinate with contractors and engineers to reduce inconsistencies on site.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.