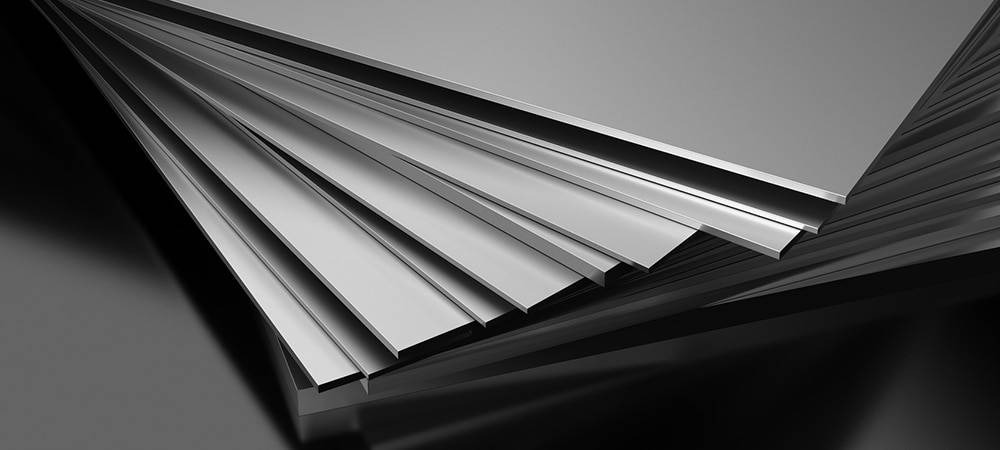

Why Stainless Steel 321 Pipes Are Perfect for Heat and Corrosion Resistance

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Stainless Steel 321 pipes are a specialized grade of austenitic stainless steel, engineered to deliver excellent performance in high-temperature environments. Stabilized with titanium, SS 321 pipes exhibit outstanding resistance to intergranular corrosion, especially after welding and exposure to temperatures ranging between 427°C to 870°C. They are widely used in heat exchangers, aircraft exhaust systems, chemical processing plants, and other industrial applications where strength and durability at elevated temperatures are critical.

What is Stainless Steel 321?

Stainless Steel 321 (UNS S32100) is a titanium-stabilized version of the popular 304 grade. The titanium addition prevents the formation of chromium carbide precipitates during welding, which helps maintain the alloy’s resistance to intergranular corrosion. As a result, SS 321 pipes are ideal for applications involving repeated heating and cooling, or long-term exposure to high heat.

Chemical Composition of SS 321 Pipes

Element Content (%)

Chromium 17.0 – 19.0

Nickel 9.0 – 12.0

Titanium ≥ 5x(C% min)

Carbon ≤ 0.08

Manganese ≤ 2.00

Silicon ≤ 1.00

Phosphorus ≤ 0.045

Sulfur ≤ 0.03

Iron Balance

This formulation enhances its high-temperature stability and corrosion resistance in oxidizing environments.

Key Features and Benefits of Stainless Steel 321 Pipes

1. Excellent Resistance to Intergranular Corrosion

Due to titanium stabilization, SS 321 pipes are resistant to carbide precipitation, making them suitable for welding and long-term exposure to high temperatures.

2. High-Temperature Strength

SS 321 retains mechanical strength and oxidation resistance up to 870°C, with intermittent service up to 925°C.

3. Good Creep Resistance

Compared to SS 304 or 304L, 321 pipes offer better creep resistance and higher strength at elevated temperatures.

4. Weldability and Fabrication

Stainless Steel 321 pipes are easy to weld using common welding techniques like TIG, MIG, and resistance welding without risk of intergranular corrosion.

5. Versatile Performance

SS 321 pipes are suitable for both oxidizing and slightly reducing environments, particularly where thermal cycling occurs.

Applications of Stainless Steel 321 Pipes

Thanks to their durability and resistance to heat and corrosion, SS 321 pipes are commonly used in:

• Heat exchangers and condensers

• Aircraft exhaust systems

• Thermal oxidizers and furnace parts

• Refinery and petrochemical equipment

• High-temperature chemical processing

• Boilers and superheaters

• Food processing and pharmaceutical equipment

Their long-term reliability makes them valuable in industries where safety and performance under pressure are crucial.

Specifications and Availability

Stainless Steel 321 pipes are available in seamless, welded, ERW, and fabricated forms.

Common Standards:

• ASTM A312 / ASME SA312

• ASTM A213 / ASME SA213

• ASTM A269 / ASTM A358

Size Range: 1/8” NB to 24” NB

Thickness: Sch 5S to Sch XXS

Length: Single Random, Double Random, or Custom Cut

Conclusion

Stainless Steel 321 pipes offer a robust and dependable solution for high-temperature, corrosive applications. Their excellent resistance to oxidation, intergranular corrosion, and stress rupture makes them an industry favorite across sectors such as petrochemical, aerospace, thermal processing, and food production. When durability, thermal stability, and corrosion resistance are essential, SS 321 pipes are a trusted and cost-effective choice.

Why Stainless Steel 321 Pipes Are Perfect for Heat and Corrosion Resistance

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.