Why to Choose Our Reverse Engineering Expertise

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In today’s fast-paced industrial and manufacturing environment, staying competitive means being able to adapt, replicate, and innovate—often under tight timelines. Whether you're modernizing legacy parts, replicating discontinued components, or improving existing designs, reverse engineering becomes an indispensable tool in your engineering arsenal. But the effectiveness of this process greatly depends on the expertise of the team behind it.

At Nel Per Tech, we specialize in delivering high-precision Reverse Engineering Servicesr that meet the evolving needs of industries ranging from aerospace and automotive to medical and consumer goods. Our team blends advanced technology with years of engineering experience to extract, digitize, and optimize physical components into usable CAD data or 3D models. Let’s explore why trusting your project to our reverse engineering experts makes all the difference.

The Value of Expert Reverse Engineering

Reverse engineering is more than just copying an object—it's a complex process that involves disassembling and analyzing components to understand their design, functionality, and performance. This process can help in:

Reconstructing legacy parts no longer in production

Improving existing designs for better performance or cost-efficiency

Conducting competitive product analysis

Creating digital models for simulation or prototyping

However, these benefits can only be realized when the reverse engineering is executed with accuracy and attention to detail. That’s where our expertise comes in.

Why Accuracy Matters

One of the most critical aspects of reverse engineering is dimensional accuracy. A small deviation can lead to a poor fit, reduced functionality, or even system failure in mission-critical applications. At Nel Per Tech, we use high-resolution 3D scanning technologies, CMMs (Coordinate Measuring Machines), and advanced metrology tools to ensure every measurement is captured with the highest precision. This minimizes the risk of errors and delivers CAD models that are as true to the original as possible.

Our Proven Process

Our Reverse Engineering Services follow a structured and transparent workflow to ensure quality at every stage:

1. Initial Assessment

We begin with a detailed discussion of your goals, whether you need a full CAD reconstruction, a partial redesign, or digital archiving. We assess the material, geometry, and condition of the original part to determine the best scanning and modeling methods.

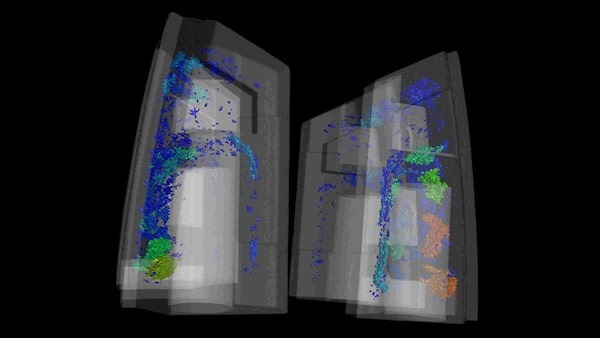

2. 3D Scanning & MeasurementWe use laser and structured light scanners to capture millions of data points from the original object. This point cloud data forms the basis of our digital model. For internal geometries, we offer industrial CT scanning to see inside without damaging the part.

3. Data Processing

Our engineers convert scan data into usable formats like mesh models, parametric surfaces, or fully editable CAD files (STEP, IGES, etc.). We apply geometric tolerancing, dimensional checks, and even simulate the part’s performance under load, if needed.

4. Validation & Delivery

Once the model is complete, we validate it through dimensional inspection and client review. Only when you’re satisfied do we deliver the final digital file, ready for manufacturing, prototyping, or design modification.

5. Ongoing Support

Our work doesn’t end at delivery. We offer continued support for design iterations, model integration, and any adjustments you may need along the way.

Technology + Talent = Superior Results

Many providers offer scanning services, but not all can transform raw data into actionable insights. At Nel Per Tech, we bridge that gap with a team of experienced engineers, CAD specialists, and metrologists who understand both the art and science behind reverse engineering.

Our Reverse Engineering Services are backed by:

High-End Equipment: We use industry-leading scanners and software to ensure precise results.

Skilled Technicians: Our team is trained in the nuances of mechanical design, tolerance analysis, and 3D modeling.

Tailored Solutions: No two parts are the same. We customize our approach based on your project’s complexity, material, and intended use.

Applications Across Industries

Our reverse engineering expertise supports a wide range of industries:

Aerospace: Reconstructing discontinued parts or improving aerodynamics

Automotive: Replacing worn components and creating performance upgrades

Medical Devices: Digitizing precision tools and anatomical models

Consumer Products: Innovating on competitor designs or legacy items

Manufacturing: Documenting and modifying tools, dies, and jigs

Each application brings unique challenges, but our proven methods and problem-solving mindset ensure consistent, high-quality outcomes.

Why Choose Nel Per Tech?

Choosing the right partner for reverse engineering isn’t just about technology—it’s about trust. When you work with Nel Per Tech, you’re partnering with a team that values precision, communication, and long-term collaboration. Here’s what sets us apart:

Fast Turnaround Times: We know speed matters. Our efficient workflows help you move from idea to implementation faster.

Confidentiality & Security: We protect your proprietary designs with strict confidentiality policies.

Flexible Service Models: Whether you need a one-off project or ongoing engineering support, we adapt to your needs.

Proven Track Record: Our satisfied clients across multiple sectors speak to the quality and reliability of our work.

With Nel Per Tech, you gain more than a service—you gain a technical partner committed to your success.

Conclusion

In an age where innovation, sustainability, and efficiency drive business success, reverse engineering stands as a strategic tool to unlock hidden value. But to truly capitalize on it, you need more than just technology—you need experience, insight, and commitment.

At Nel Per Tech, our Reverse Engineering Services are designed to help you move forward by understanding what came before. Whether you're trying to replicate, improve, or reimagine a part or product, we’re here to guide you every step of the way.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.