Why Valve Lockout Devices are Essential for Energy Isolation and Hazard Prevention

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

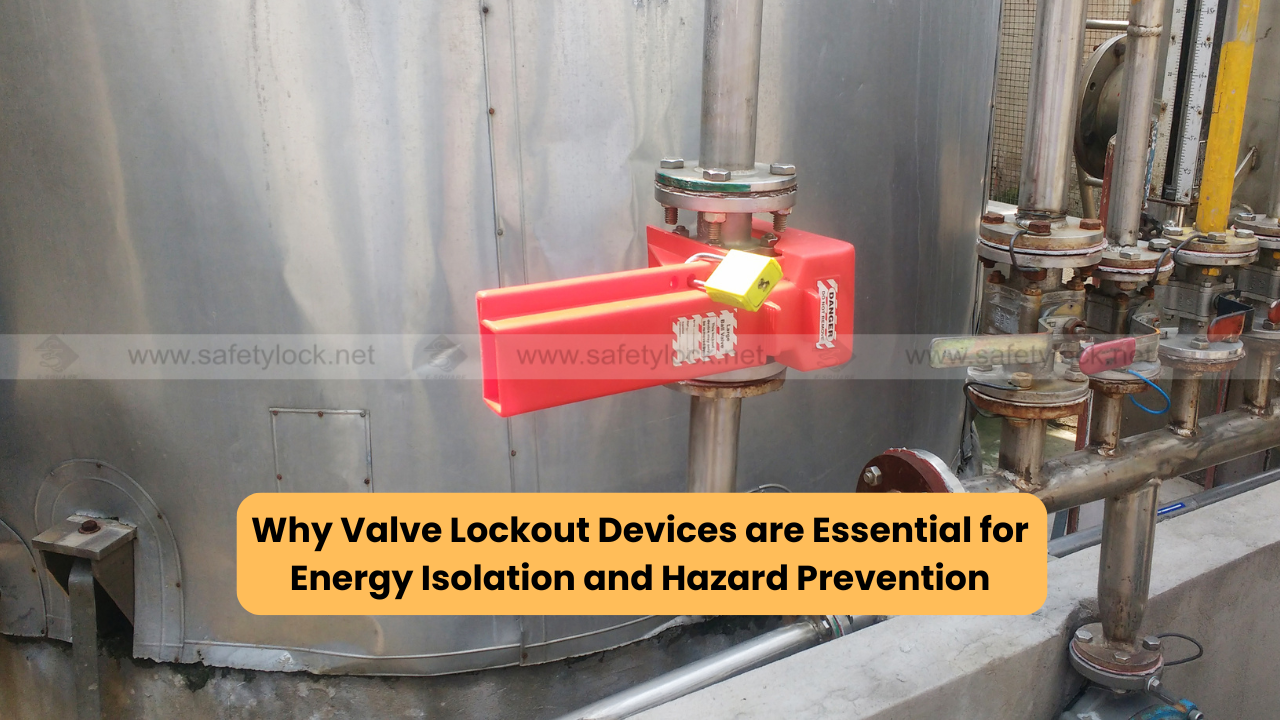

In industrial environments, machinery and equipment often rely on energy sources such as gas, steam, water, or chemicals - controlled via various types of valves. These valves regulate the flow and release of hazardous energy, making them a vital part of plant operations. However, if improperly managed, they can pose severe risks to workers during maintenance or service procedures. That’s where valve lockout devices come into play.

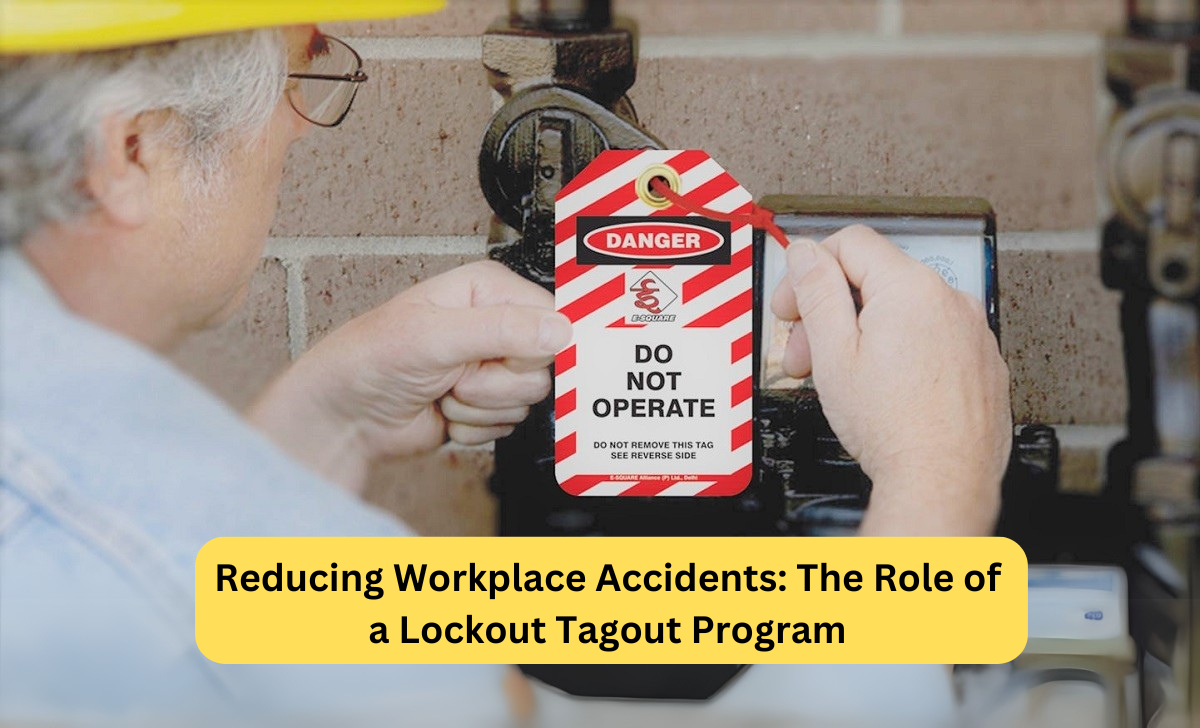

Valve lockout devices are engineered to prevent the accidental or unauthorized operation of valve-controlled energy sources. They are a fundamental component of any Lockout Tagout safety program, helping organizations comply with safety regulations and protect their workforce from potentially fatal incidents.

Understanding the Role of Valve Lockout Devices

Valve lockouts are designed to physically restrict a valve’s ability to open or close, thereby isolating the energy source entirely. During maintenance or shutdowns, these devices ensure that valves remain in a secure, fixed position - whether fully open or closed - until the work is complete and it is safe to resume operations.

Different types of valve lockouts are available to accommodate the wide variety of valve shapes, sizes, and mechanisms, such as ball valves, gate valves, butterfly valves, and plug valves. Each design aims to ensure maximum security, visibility, and compliance with safety procedures.

Types of Valve Lockout Devices

Depending on the valve type, different lockout devices are available:

• Ball Valve Lockouts: Encase the handle in a way that it cannot be moved from its locked position.

• Gate Valve Lockouts: Cover the handwheel to prevent it from being turned.

• Butterfly Valve Lockouts: Typically clamp over the valve handle to immobilize it.

• Plug Valve Lockouts: Designed to secure valves used in chemical or fluid transfer systems.

These devices are often made of durable materials like steel or high-impact plastic and are color-coded for quick visual identification. Many also feature spaces for padlocks and tags, allowing for multiple workers to lock out the same valve during group maintenance activities.

Why Valve Lockout Devices are Essential

Here are the key reasons valve lockout devices are essential for industrial safety:

1. Prevent Accidental Energy Release

During maintenance, any accidental release of pressure, gas, steam, or liquid due to an unsecured valve can cause severe injuries or even fatalities. Valve lockouts ensure the energy source remains isolated until all personnel have completed their work and the system is safe to activate.

2. Ensure Compliance with Safety Regulations

Organisation like OSHA (Occupational Safety and Health Administration) require industries to implement proper lockout tagout procedures. Using valve lockout devices is a direct way to comply with these regulations, avoiding penalties and ensuring a legally sound safety framework.

3. Reduce Workplace Injuries and Downtime

Injuries due to valve-related incidents can result in significant downtime, compensation claims, and loss of workforce morale. Lockout devices help prevent such accidents, reducing disruptions and maintaining productivity while prioritizing employee safety.

4. Promote a Culture of Safety

Installing lockout devices reinforces a strong message: safety comes first. When workers see physical barriers and clear tags on valves, it enhances awareness, encourages adherence to protocols, and fosters accountability throughout the team.

5. Accommodate a Wide Range of Industrial Applications

From oil refineries to food processing plants, valve lockout devices are versatile. They can be used in any industry where energy isolation is necessary, making them a universal tool for safeguarding employees and processes alike.

Conclusion

Valve lockout devices play a crucial role in modern industrial safety systems. They provide a simple yet powerful means to control hazardous energy, prevent unauthorized access, and safeguard the lives of workers during maintenance operations.

Beyond compliance, their real value lies in their ability to turn everyday operations into predictable, safe procedures. Whether you're upgrading an existing safety program or building one from scratch, investing in quality valve lockout devices is a step toward creating a safer, more responsible workplace.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.