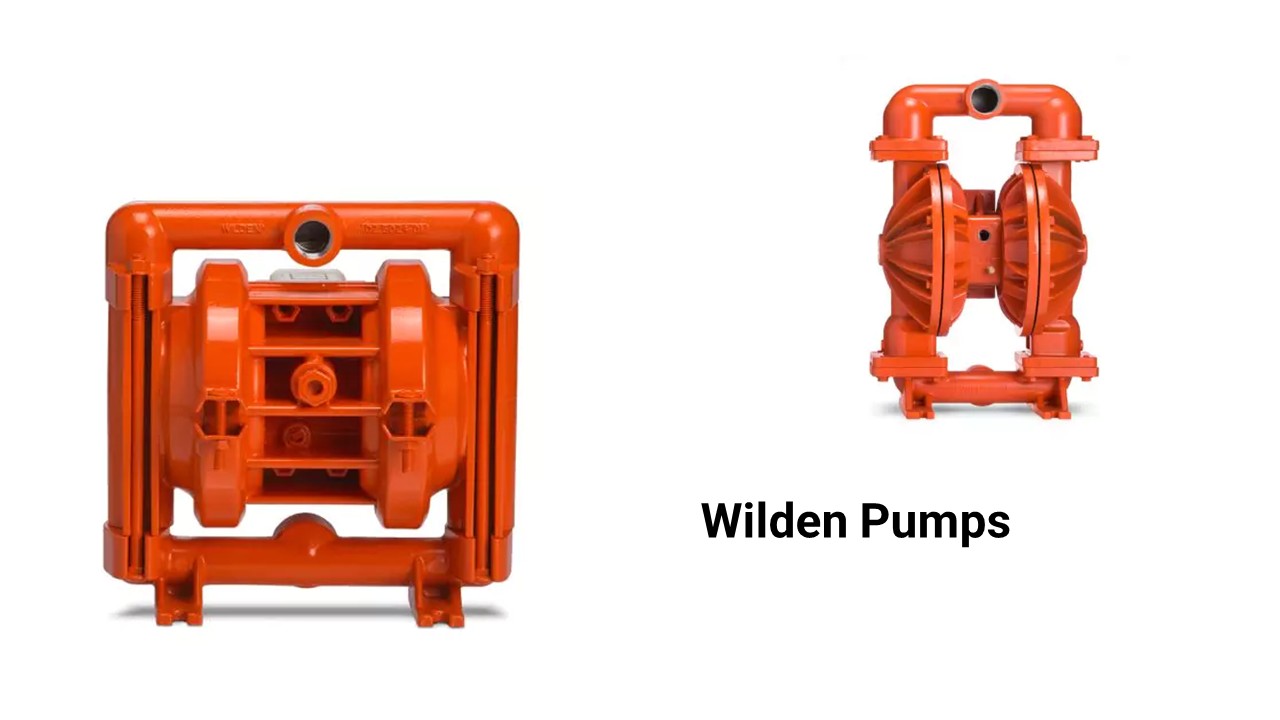

Why Wilden Pumps Are The Best For Viscous And Abrasive Fluid Handling

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Air-operated double diaphragm (AODD) pumps are currently a standard in companies that need dependable, energy-efficient, and multitalented fluid handling. Wilden Pump is one of the top brands in the market that has the privilege of being a byword for innovation, build quality, and performance.

Overview of Wilden Pump

Wilden, the leader in AODD technology, has set industry standards since the company began. Wilden pumps can handle abrasive materials, high-viscosity slurries, chemicals, and water. The pumps range in size from 203 mm (8") to 6 mm (¼"). They can be used in many industrial applications and provide high flow rates along with operational flexibility.

Important attributes and advantages

Energy-efficient: Compared to other AODD technologies, Wilden's Pro-Flo SHIFT Air Distribution System (ADS) offers 34% higher flow rates and 60% energy savings. All of this means lower operating costs and also, generally doubles the MTBR, an advantage that leads to improved productivity overall.

Long-Term Construction: Wilden pumps can come with bolted and clamped types. Bolted types provide improved product containment with increased flow rates, whereas clamped types are appreciated for simplicity of installation and maintenance.

Flexibility: The mining, oil and gas, food and beverage, water and wastewater treatment, chemical processing, and biopharmaceutical industries all use the pumps extensively.

Handling Sensitive Products: Sensitive or shearing-prone fluids can be managed by the Wilden AODD pumps. They suit industries where product quality has to be preserved, including the food, beverage, and pharmaceutical sectors.

Self-running capability refers to Wilden pumps' capacity to self-prime and run dry without endangering themselves. This feature guarantees their reliability, even in tough working conditions.

Solids Handling: Certain models, such as the Stallion Series, are built to handle solid-charge slurries. They are therefore very useful in mining and other high-usage applications.

Uses in Various Industries

Numerous industries make use of wilden pumps:

Chemical processing: Apply the polymers to dosing, acid transferring, and solvent control.

Mining: The abrasion-resistant types are able to transfer abrasive slurries and heavy solids without plugging.

Food and Beverage: The Sanitary types are FDA, EHEDG, and 3A compliant for safe and sanitary product handling.

Oil and gas: You need reliable performance and strong containment for high-risk use.

Water and Wastewater: Made to improve the efficiency of treating fluids with abrasives or particles.

Why Choose Wilden Pump?

Wilden's dedication to the latest in technology is realized in its ongoing product improvements, including Chem-Fuse Diaphragm for leak protection and FIT metal pump series for flow efficiency and ease of maintenance. Years of demonstrated reliability, technical assistance, and full line of accessories to ensure pump performance form the foundation of their global reputation.

Conclusion

A globally recognized leader in the AODD technology, Wilden Pump offers heavy-duty, energy-efficient, and highly versatile solutions for nearly all fluid handling issues. Wilden pumps combine uncompromising reliability, operating efficiency, and ease of maintenance for demanding industrial applications or severe sanitary environments-which is why the first choice for companies whose pay for results and Peace of Mind.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.